Description

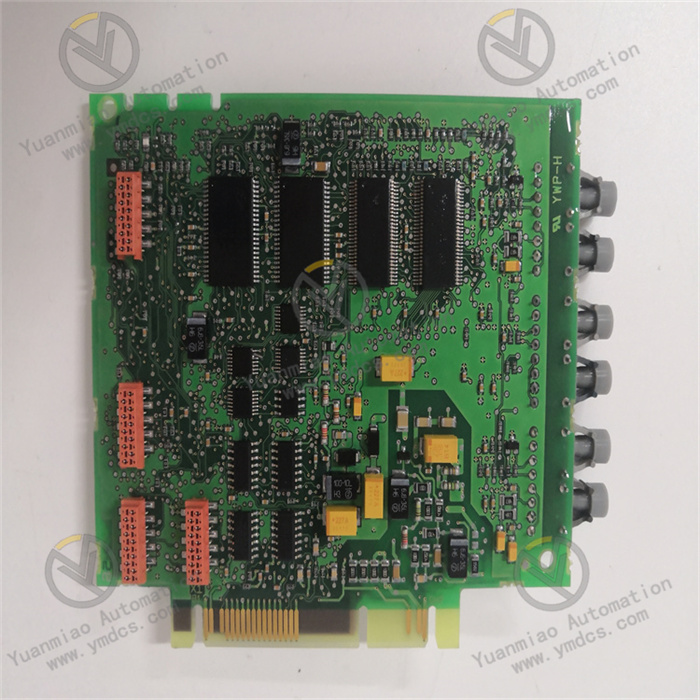

ABB CI531 3BSE003825R1

ABB CI531 3BSE003825R1

Overview

The ABB CI531 3BSE003825R1 is a communication interface module in the field of industrial automation, primarily used to enable data interaction and communication between devices in process control systems. Designed to be compatible with ABB's control systems (such as AC 800M), it acts as a bridge between field devices and control systems, supporting multiple communication protocols to ensure efficient collaborative operation of industrial equipment. It is commonly used in scenarios requiring high-reliability communication, such as power, chemical, and manufacturing industries.

Functional Features

- Strong Protocol Compatibility

Supports industrial communication protocols such as Modbus RTU and Modbus ASCII, enabling data interaction with third-party devices (e.g., sensors, actuators). - High-Speed Data Transmission

Features efficient data processing capabilities and supports real-time communication to ensure fast transmission of control commands and feedback information. - Hardware Redundancy Design

Supports hot-swapping and redundant configuration (e.g., dual-module backup), reducing system downtime risks and enhancing reliability in industrial applications. - Anti-Interference Capability

Adopts industrial-grade protection design, enabling stable operation in harsh environments with electromagnetic interference and temperature fluctuations. - Flexible Configuration

Customizable communication parameters (baud rate, data bits, parity, etc.) via software tools (e.g., ABB Control Builder) to adapt to different application scenarios.

Technical Parameters

| Parameter Type | Specific Indicators |

|---|---|

| Communication Interface | RS-485 interface (supports 2 independent channels), supporting half-duplex communication. |

| Baud Rate Range | 1200bps to 115.2kbps, adjustable as needed. |

| Electrical Isolation | Electrical isolation between channels, isolation voltage ≥500V AC, enhancing anti-interference capability. |

| Operating Voltage | 24VDC (±10%), power consumption approximately 5W. |

| Protection Class | The module's protection class is IP20, suitable for installation in control cabinets. |

| Ambient Temperature | Operating temperature: -20℃ to +60℃; storage temperature: -40℃ to +85℃. |

| Dimensions (L×W×H) | Approximately 170mm×40mm×200mm, adapting to standard control cabinet installation space. |

| Certifications | Complies with international safety standards such as CE and UL, suitable for global industrial scenarios. |

Working Principle

The CI531 module receives Modbus protocol signals from field devices via the RS-485 interface. First, it performs electrical isolation and filtering on the signals to avoid interference affecting data accuracy. Then, it parses the protocol content (such as address, function code, data frame) through an internal processor, converting physical layer signals into digital signals recognizable by the control system. Meanwhile, the module can encode commands issued by the control system into Modbus protocol frames and transmit them to field devices via the interface, achieving bidirectional communication. Its redundancy design ensures that when a single module fails, the backup module can automatically take over communication tasks to maintain continuous system operation.

Common Faults and Solutions

- Communication Interruption

- Possible causes: Damaged communication cable, poor interface contact, incorrect baud rate/parity parameter settings.

- Solutions: Check cable connections and replace damaged cables; use a multimeter to test interface voltage; reconfigure communication parameters via Control Builder to ensure consistency with devices.

- Data Transmission Error

- Possible causes: Electromagnetic interference, incorrect protocol frame format, module hardware failure.

- Solutions: Add a shielding layer to the cable and ensure reliable grounding; check if the data frame format complies with Modbus protocol specifications; detect module status via diagnostic software and replace the module if there is a hardware failure.

- Abnormal Module Indicator Lights

- Possible causes: Power failure, abnormal communication link, failed redundancy configuration.

- Solutions: Check if the 24VDC power input is stable; confirm whether the redundant module connection is normal; if the indicator lights continue to report errors, try restarting the module or restoring factory settings.

- Hot-Swap Failure

- Possible causes: Hot-swapping not performed according to specifications, resulting in interface chip damage.

- Solutions: Ensure the module is replaced when powered off; if the chip is damaged, contact ABB after-sales service to replace the internal circuit board of the module.

Application Scenarios

- Process Control

Connects field instruments such as flowmeters and pressure transmitters to transmit real-time data to the DCS system. - Equipment Monitoring

Communicates with frequency converters and motor controllers to achieve remote adjustment and monitoring of parameters such as rotation speed and current. - Industrial Automation Production Lines

Coordinates the action timing and data interaction of multiple devices in scenarios such as automotive manufacturing and food processing.