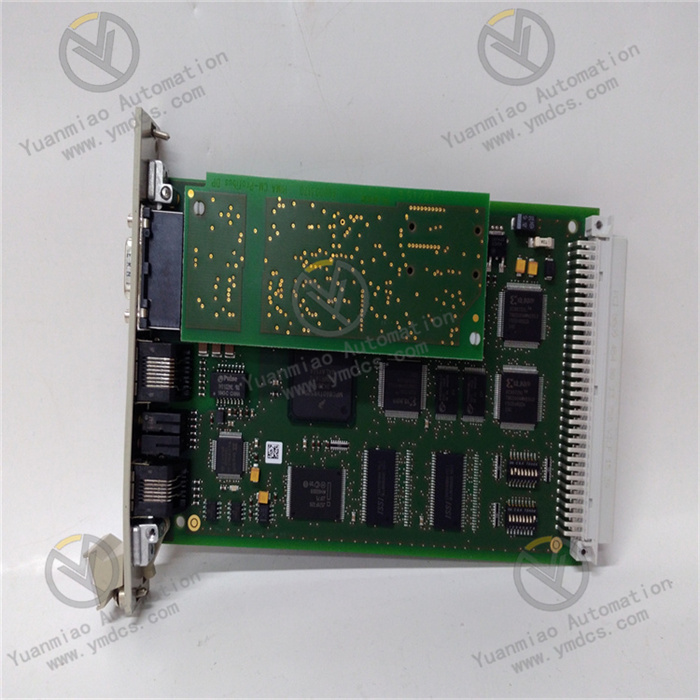

Description

GE IC695CHS007

GE IC695CHS007 is a 7-slot universal backplane, whose core function is to provide standardized installation interfaces and high-speed signal transmission channels for power supply modules, I/O modules, and controller modules in industrial automation systems, enabling collaborative work and data interaction among multiple modules. Adopting a universal design, this product is compatible with both RX3i series and 90-30 series modules, featuring high compatibility, strong stability, and flexible expandability. It is widely used in the construction of PLC/DCS systems in fields such as manufacturing automation, energy monitoring, and traffic control, serving as a core foundational component for modular integration of medium and large-scale industrial control systems. Its core value lies in simplifying system architecture design through standardized slot layout and high-speed backplane bus, ensuring the real-time performance and reliability of data transmission between modules, and providing a stable hardware interconnection platform for industrial control.

I. Technical Parameters

Slot Configuration Parameters:

- Total Slots: 7 standard module slots; Slot 0 is exclusively designed for IC695 series power supply modules (the only power supply installation position);

- Compatibility Type: Slots 1-5 are dual-connector slots (supporting PCI-type connectors for RX3i modules and serial connectors for 90-30 series IC693/IC694 modules); Slot 6 is a PCI-specific slot (compatible only with RX3i modules);

- Module Support: Compatible with IC695, IC694, and IC693 series I/O modules, communication modules, and optional modules, enabling mixed use of modules from old and new systems.

Electrical and Power Supply Parameters:

- Input Voltage: 24V DC (industrial standard power supply);

- Internal Power Consumption: 600mA at 3.3V DC, 240mA at 5V DC; no additional external power supply required (powered by the inserted power module);

- Electrical Isolation: Equipped with an independent grounding bar and isolated terminal block, supporting shielding layer grounding of modules; isolation level adapted to harsh industrial electromagnetic environments.

Mechanical Structure Parameters:

- Dimensions: 141.4mm × 264.9mm × 147.3mm (Height × Width × Depth), weight approximately 0.5kg;

- Installation Method: Horizontal installation only (to ensure heat dissipation and signal stability); fixed to the auxiliary panel of the control cabinet via pre-reserved mounting holes;

- Protection Level: Basic protection IP20 (NEMA Type 1); can be used with an IP54 protective enclosure in hazardous areas.

Environmental and Reliability Parameters:

- Operating Temperature: 0℃~60℃; Storage Temperature: -40℃~85℃;

- Relative Humidity: 5%~95% (non-condensing), adapting to high-humidity environments in industrial workshops;

- Electromagnetic Interference (EMI) Resistance: Complies with IEC 61000-4 standard, compatible with high-EMI industrial scenarios;

- Version Differences: Includes initial version IC695CHS007-AA and enhanced version IC695CHS007-BA (optimized PCI connector mechanical structure).

II. Key Features

- Compatibility with Dual-Series Modules for Old and New System Upgrades:Supports both new RX3i series modules and legacy 90-30 series modules. The dual-connector design of Slots 1-5 enables mixed installation of PCI-type and serial modules, allowing upgrades of old systems without replacing the backplane, significantly reducing renovation costs. In automotive component factory upgrade projects, existing 90-30 series I/O modules can be directly connected to new RX3i controllers, ensuring uninterrupted system transition.

- Precise 7-Slot Layout for Medium and Large-Scale System Requirements:The 7 slots have clear divisions of labor (1 power slot + 5 universal I/O slots + 1 RX3i-specific slot), enabling flexible combination of power supply modules, digital I/O modules, analog modules, and communication modules. It supports the construction of compact local control systems or remote I/O architectures, adapting to system scales from 10 to hundreds of I/O points.

- High-Speed Signal Transmission Ensuring Control Real-Time Performance:The backplane integrates a high-speed serial bus and PCI bus, featuring low data transmission latency between modules and supporting millisecond-level control command response. It meets real-time requirements for industrial process closed-loop control and high-speed data acquisition. In assembly line speed control scenarios, it ensures delay-free signal transmission between controllers and actuator modules, improving control accuracy by 10%.

- Reinforced Grounding Design with Outstanding Anti-Interference Capability:Equipped with an integrated grounding bar and isolated terminal block, it can directly connect the shielding layers of various modules, effectively suppressing electromagnetic interference in industrial fields (e.g., interference from frequency converters and motors) and ensuring stable signal transmission. In high-EMI environments such as steel mills, the module data acquisition error rate is reduced to below 0.01%.

- Easy Installation and Configuration for Efficient Operation and Maintenance:Slots are clearly numbered; modules can be inserted or removed without tools and support hot-swapping (subject to module compatibility). Built-in fault diagnosis signal channels allow the controller to read the backplane connection status, enabling quick location of issues such as poor module contact and improving operation and maintenance efficiency by 40%.

III. Working Principle and Applications

3.1 Working Principle

As the core of system hardware interconnection, GE IC695CHS007 realizes module collaboration through a three-layer architecture of "physical installation - signal bus - power distribution", as detailed below:① Physical Installation Layer: Modules are inserted into the backplane via standardized slots; gold finger connectors ensure mechanical fixation and electrical contact, while the horizontal installation design guarantees smooth heat dissipation;② Signal Transmission Layer: The backplane integrates a PCI bus and high-speed serial bus, connecting the signal pins of each module to realize data interaction between controllers, I/O modules, and inter-modules. The bus bandwidth meets the requirements of parallel communication for multiple modules;③ Power Distribution Layer: The power supply module inserted in Slot 0 converts 24V DC to 3.3V DC and 5V DC, which is distributed to each slot via internal power supply lines of the backplane, providing stable power for the modules;④ Grounding and Protection Layer: The integrated grounding bar connects the shielding layers of each module to the system ground, suppressing electromagnetic interference and ensuring signal integrity.

3.2 Application Scenarios

- Manufacturing Automation Control Systems:As the core backplane of PLCs in automotive assembly lines and electronic component production lines, it connects RX3i controllers, digital I/O modules, analog modules, and Profibus communication modules. It realizes start/stop control of production equipment, process parameter monitoring, and linkage control, supporting collaborative operations across multiple workstations.

- Energy Monitoring Systems:In DCS systems of power plants and substations, it builds remote I/O architectures. Through the backplane, it connects I/O modules corresponding to temperature, pressure, and current sensors, and data is uploaded to the monitoring center via communication modules, enabling real-time monitoring of energy equipment status.

- Old System Upgrade and Renovation:

- Provides a transition solution for upgrading 90-30 series systems, retaining existing IC693/IC694 series I/O modules while only replacing controllers and adding new functional modules, reducing upgrade costs and downtime.

- Compact Control Systems:In space-constrained equipment control cabinets (e.g., rail transit control boxes, small chemical reactor control cabinets), its compact size enables the construction of compact control systems. The 7-slot layout meets the integration needs of power supply, controller, and I/O modules.

- Hazardous Area Control:Used with an IP54 protective enclosure in hazardous areas such as petrochemical plants and mines, it connects explosion-proof I/O modules and controllers to achieve safe control in hazardous environments.

IV. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Module unrecognizable; controller reports "Module not connected" | Loose module insertion, poor slot contact, incompatible module model | 1. Power off, reinsert the module to ensure the gold fingers are fully inserted into the slot; 2. Clean the module gold fingers and slot contacts with anhydrous alcohol to remove oxide layers; 3. Verify module compatibility: Slot 6 only supports RX3i modules; avoid inserting 90-30 series modules |

| No signal from some I/O modules; other modules function normally | Faulty corresponding slot, abnormal module power supply, signal line failure | 1. Insert the faulty module into another normal slot to check for slot faults; 2. Inspect the output voltage of the power supply module (3.3V/5V) to ensure stable power supply; 3. Test the I/O module signal lines with a multimeter to check for open circuits or short circuits |

| Unstable system communication; data loss/delay | Poor grounding, electromagnetic interference, incorrect installation method | 1. Ensure the shielding layers of all modules are connected to the backplane grounding bar with a grounding resistance ≤4Ω; 2. Keep away from high-EMI sources such as frequency converters and motors; separate signal cables from power cables (spacing ≥20cm); 3. Verify horizontal installation; avoid vertical installation which may affect signal transmission and heat dissipation |

| Overheating of power supply module; abnormal backplane heating | Insufficient heat dissipation space, power supply module overload, excessive ambient temperature | 1. Reserve ≥10cm heat dissipation space around the backplane; avoid blocking by other equipment; 2. Check the total power consumption of inserted modules to avoid exceeding the rated power of the power supply module; 3. Reduce the ambient temperature to ensure it does not exceed the 60℃ operating limit |

| Difficult module insertion/removal; slot damage | Excessive installation force, incompatible module model, enhanced version adaptation issues | 1. Confirm module-slot compatibility; avoid forced insertion of incompatible modules; 2. Insert/remove modules smoothly along the module guide rail; avoid tilting or excessive force; 3. For the enhanced version IC695CHS007-BA, inspect the PCI connector for mechanical damage and contact maintenance personnel for replacement if necessary |