Description

ABB PPD113B01-25-111000

The ABB PPD113B01-25-111000 is part of the AC800PEC control system. Widely used in industrial automation, this system is renowned for its high reliability, powerful processing capabilities, and flexible configuration, making it suitable for industrial control scenarios of various scales and complexities, such as power, chemical, metallurgical, and pharmaceutical industries. It is used for precise control and monitoring of various industrial processes, enabling functions such as sequential control, ladder logic control, accident recall processing, analog-digital conversion, input/output signal processing, data communication, and data processing.

Functional Features

- Powerful Control Functions: Equipped with multiple control algorithms and function blocks, it can implement complex control strategies such as PID control and fuzzy control to meet the control requirements of different industrial processes.

- Signal Processing Capability: Capable of handling various types of input signals, including analog, digital, resistance temperature detectors (RTDs), and thermocouples, while providing corresponding output signals to control actuators. For example, it may have multiple analog input channels that can connect to sensors for temperature, pressure, and flow, converting analog signals into digital signals for processing; it also has digital input/output channels for interacting with switches, relays, and other devices.

- Communication Capability: Supports multiple communication protocols such as MODBUS, PROFIBUS, and ETHERNET, facilitating seamless communication and data exchange with other devices to achieve system integration and expansion. Through communication networks, the module can be connected to supervisory control and data acquisition (SCADA) systems, other controllers, or intelligent devices for remote monitoring and management.

- Reliability Design: Incorporates redundancy technology, fault diagnosis, and self-protection functions to enhance system reliability and stability. For instance, it may feature power redundancy and communication redundancy, automatically switching to backup components in case of a failure to ensure continuous operation; it also includes protection functions against overcurrent, overvoltage, overheating, etc., to safeguard the module and other devices from damage.

Technical Parameters of ABB PPD113B01-25-111000 Module

1. Electrical Parameters

| Parameter | Description |

|---|---|

| Rated Power | 25kW (the "25" in the model indicates this parameter, suitable for medium-capacity excitation systems or industrial power control) |

| Input Voltage Range | - DC input: Typically compatible with 110VDC or 220VDC (specific to system design, supporting wide voltage input) |

| Output Voltage Range | Adjustable DC voltage (e.g., 0–250VDC, used for excitation control or motor drive; subject to confirmation in the manual) |

| Output Current Range | Typical 0–125A (supports short-term overload, such as 150% of rated current for 30 seconds) |

| Efficiency | ≥92% (high-efficiency design reduces energy consumption and heat generation) |

| Frequency Response | Supports dynamic response (response time ≤20ms, adapting to fast adjustment needs) |

| Ripple Coefficient | ≤3% (low-ripple output reduces interference with precision equipment) |

2. Mechanical and Environmental Parameters

| Parameter | Description |

|---|---|

| Dimensions | Standard rack-mounted design (e.g., 2U height, 19-inch rack mounting; dimensions approx.: 482.6mm×300mm×133mm) |

| Weight | Approximately 10–12kg (metal casing with enhanced heat dissipation and anti-vibration capabilities) |

| Operating Temperature | -10°C–+55°C (industrial-grade wide temperature range, adapting to harsh environments) |

| Storage Temperature | -25°C–+70°C |

| Humidity | 5%–95% non-condensing |

| Protection Class | IP20 (indoor installation, protected against solid foreign objects; requires use with a control cabinet) |

| Installation Method | Horizontal rack mounting, supports rail fixation (requires reserved heat dissipation space) |

3. Control and Communication

| Parameter | Description |

|---|---|

| Control Mode | - Analog control: 4–20mA or 0–10V input - Digital control: Supports MODBUS RTU protocol |

| Communication Interface | RS-485 (standard), optional Ethernet (RJ45) or fiber optic interface |

| Protection Functions | - Overvoltage protection (OVP) - Overcurrent protection (OCP) - Overheat protection (OTP) - Short-circuit protection (SCP) - Undervoltage protection (UVP) |

| Redundancy Design | Supports parallel redundancy (improves system reliability, automatic switching in case of failure) |

| Signal Feedback | Real-time feedback of parameters such as output voltage, current, temperature, and fault status to the controller or SCADA system |

4. Functional Characteristics

- Modular Design: Supports expansion of multiple I/O modules (e.g., analog input/output, digital input/output) and adapts to different signal types (voltage, current, HART, etc.). Flexibly configurable communication interfaces (e.g., Anybus/Modbus RTU) are compatible with mainstream industrial buses.

- High-Precision Control: Voltage/current control accuracy of ±1.5% of rated value ensures output stability. Fast dynamic response adapts to sudden load changes (e.g., generator excitation regulation).

- High Reliability: Uses IGBT power devices, resistant to high voltage and current, supporting long-term full-load operation. Intelligent temperature-controlled cooling system (automatic fan start/stop + large heat sink) reduces noise and extends service life. Built-in EMI filter provides strong anti-electromagnetic interference capability, suitable for complex industrial environments.

- Status Monitoring and Maintenance: Front-end indicator lights (fault, operation, warning) display module status in real time. Supports remote monitoring and fault diagnosis, reducing downtime.

5. Application Scenarios

- Power Industry: Excitation control of synchronous generators (such as steam and hydro turbines) to maintain grid voltage stability.

- Industrial Automation: Power regulation in motor drive systems and process control (e.g., chemical, metallurgical, rail transit industries).

- Renewable Energy: Excitation control or power regulation for energy storage systems and synchronous compensators.

6. Comparison with Series Products (Example)

| Parameter | PPD113B01-20-111000 | PPD113B01-25-111000 | Difference Description |

|---|---|---|---|

| Rated Power | 20kW | 25kW | 25% power increase, suitable for larger loads |

| Output Current | 0–100A | 0–125A | Increased current capacity for high-excitation needs |

| Overload Capacity | 150%/30s | 150%/45s | Longer short-term overload duration |

| Communication Protocol | MODBUS RTU | MODBUS RTU | Same protocol, optimized hardware performance |

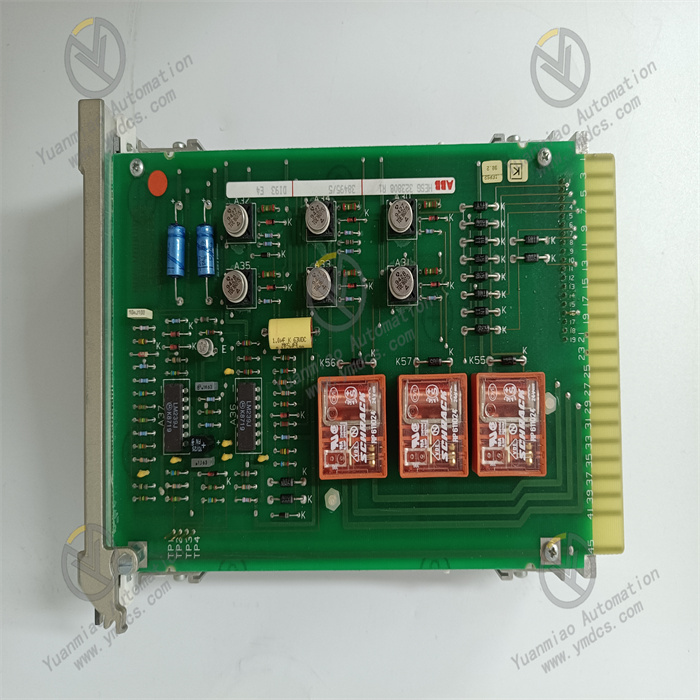

Appearance and Installation

- Appearance Design: Typically adopts a standard industrial module form factor with a compact structure, facilitating installation in control cabinets or equipment. The module surface may have status indicator lights to display working conditions such as power status, communication status, and fault status, enabling operators to conduct on-site monitoring and fault troubleshooting.

- Installation Method: Supports multiple installation methods such as rail mounting and panel mounting, which can be selected according to actual application scenarios and installation requirements. The installation process is simple and convenient, allowing quick completion of module installation and cabling.