Description

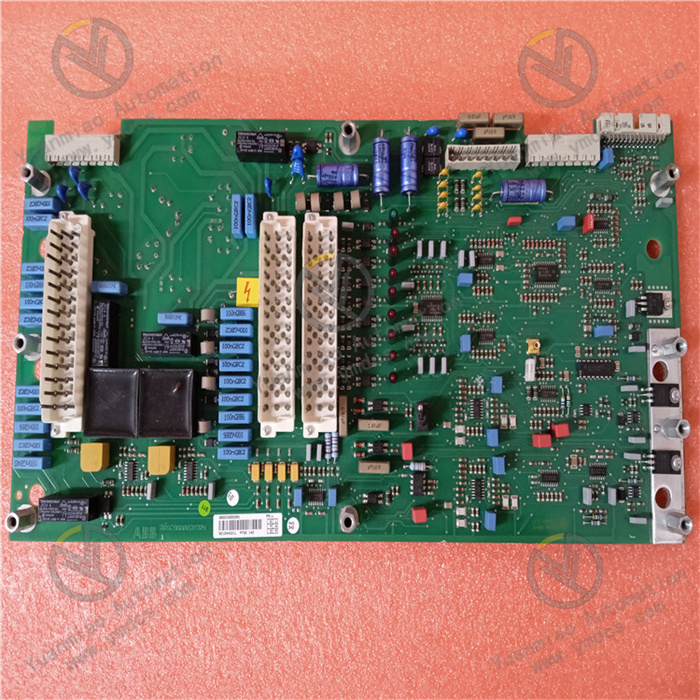

ABB PFSK142 3BSE006505R1

ABB PFSK142 (Order No. 3BSE006505R1) is a communication interface module specially designed for conventional data interaction scenarios in industrial Distributed Control Systems (DCS). It integrates ProfiBus DP bus communication and the system's internal SBUS interface functions, serving as a cost-effective communication hub component that connects Field Control Units (FCU), third-party intelligent devices and the main control system. With its high cost performance, stable signal transmission capability and convenient operation and maintenance features, this module is widely used in industrial scenarios with low requirements for communication redundancy, such as power generation, metallurgy and light industry, providing reliable support for the basic data interaction of DCS.

1. Product Attributes

Positioned as a cost-effective universal communication bridge unit of the Advant OCS 400 system, this module is distinguished from the redundant modules in the same series. It focuses on the basic requirements of industrial-grade data interaction while balancing cost control and system compatibility. The specific basic information is as follows:

- Product Model: PFSK142 (Order No.: 3BSE006505R1)

- Product Type: Industrial-grade non-redundant communication interface module, compatible with the Advant OCS 400 DCS. It integrates ProfiBus DP V0 master/slave station and ABB SBUS bus communication functions, supports two-way transmission of basic data, and is a cost-effective communication component for distributed control of small and medium-sized industrial installations.

- Core Purpose: Serving as a universal communication gateway of the Advant OCS 400 system, it receives process data (temperature, pressure, flow rate, etc.) collected by field I/O modules and transmits the data to the main control system via the ProfiBus DP bus; meanwhile, it receives control commands issued by the main control terminal and forwards them to field execution units. It supports local indication of link status, facilitating maintenance personnel to quickly identify communication faults. Suitable for small and medium-sized DCS with non-redundant architecture, it meets the requirements of conventional process parameter monitoring and control.

2. Technical Specifications

2.1 Electrical and Communication Performance Parameters

| Parameter Category | Core Indicators | Description |

|---|---|---|

| Communication Protocol | Supports ProfiBus DP V0 and ABB SBUS | ProfiBus DP is used to connect third-party conventional devices (frequency converters, PLC, general instruments); SBUS is used for basic data interaction between FCU and the main control unit within the system |

| Communication Rate | ProfiBus DP: up to 12 Mbps; SBUS: 2 Mbps | Supports automatic rate adaptation, matching the transmission rate according to bus length. The maximum bus length is 100m at a rate of 12 Mbps |

| Redundancy Design | Single ProfiBus DP interface + single SBUS interface, no redundant switching function | Suitable for scenarios with general requirements for system availability. Manual switching to the standby module is required in case of faults |

| Data Interaction Capability | Supports transmission of up to 1024 digital I/O points / 256 analog I/O points | The data refresh cycle is < 200ms, adapted to the conventional parameter monitoring and control requirements of small and medium-sized industrial installations |

| Power Supply Requirements | 24V DC single-channel power supply, power consumption ≤ 10W | Supports wide voltage input (20~28V DC), adapted to the conventional DC power supply environment of industrial sites |

2.2 Physical and Protection Specifications

- Dimensions and Weight: Approximately 200mm × 115mm × 55mm in size, with a net weight of about 0.6kg. The compact design is fully compatible with the installation dimensions of the PFSK151/PFSK152 modules in the same series, allowing direct replacement and upgrade.

- Protection and Material: The housing is made of high-strength engineering plastic with an IP20 protection rating (for cabinet installation). Its vibration resistance complies with IEC 60068-2-6 standard (5-150Hz, amplitude 0.1mm), adapting to the conventional mechanical vibration environment of industrial sites.

- Installation Method: DIN rail mounting, connected to the system motherboard via a standard backplane connector. Wiring adopts screw terminal blocks with anti-loosening design, enabling easy disassembly and assembly without professional tools.

- Interface Configuration: 1×ProfiBus DP bus interface (DB9 connector), 1×SBUS interface (ABB dedicated connector), 1×status indicator light (Power/Run/Communication).

2.3 Environmental Adaptability

- Temperature Range: Operating temperature: 0℃~+55℃; Storage temperature: -20℃~+70℃. Adapted to the working conditions of conventional industrial workshops, but not applicable to extreme alpine or high-temperature environments.

- Anti-interference Performance: With 2kV surge protection capability, its electromagnetic interference suppression complies with IEC 61000-4 standard, resisting interference from conventional electromagnetic radiation equipment in industrial sites.

Humidity Adaptability: Operating humidity: 10%~90% (non-condensing). It can operate stably for a long time in industrial environments with conventional humidity.

3. Compatible Systems and Hardware Combinations

Compatible Control Systems: Core compatibility with the ABB Advant OCS 400 distributed control system (non-redundant architecture). It can be used as a communication master station to connect third-party ProfiBus DP devices, or as a slave station to access the upper-layer SCADA system. It is compatible with the basic extended applications of the ABB Symphony Plus system (protocol conversion gateway required).

- Supporting Equipment and Links: Connectable to ABB Advant OCS 400 series FCU control units, conventional DI/DO/AO/AI modules, as well as third-party ProfiBus DP devices (e.g., ABB ACS510 frequency converters, Siemens S7-200 PLC, general electromagnetic flowmeters). Shielded twisted-pair cables are recommended for ProfiBus bus connection. 120Ω terminating resistors must be connected at both ends of the bus, and the shielding layer should be grounded at a single point with a grounding resistance ≤ 4Ω.

- Expansion and Linkage: Supports basic linkage with the ABB Industrial IT system to realize remote data monitoring. The firmware version can be checked via the backplane bus, and parameter configuration must be completed through the ABB Control Builder Basic software. Multi-module parallel deployment is supported, adapting to the regional communication requirements of small and medium-sized industrial installations.

4. Product Features

High Cost Performance, Adapted to Conventional Scenarios

Installation Compatibility, Convenient Upgrade

Stable and Reliable, Simple Operation and Maintenance

Multi-device Compatibility, Flexible Integration

5. Application Scenarios and Safe Operation Precautions

5.1 Application Scenarios

- Power Generation Industry: Used in the DCS of small waste heat generator sets and substation auxiliary systems to realize the monitoring and control of conventional process parameters, ensuring the stable operation of equipment.

- Metallurgical Industry: Adapted to the automatic control systems of small rolling and heat treatment production lines, transmitting conventional process data such as temperature and speed to meet the basic control requirements of the production lines.

- Light Industry: Used in small and medium-sized production installations in industries such as food and papermaking, connecting field instruments and actuators to realize automatic monitoring and simple adjustment of the production process.

5.2 Safe Operation and Maintenance Specifications

- Installation and wiring must be performed by professional technical personnel. Before operation, the system power supply must be disconnected, and no voltage must be confirmed before disassembling and assembling the module to avoid electric shock or module damage.

- ProfiBus bus wiring must strictly follow the principles of terminating resistor matching and single-point grounding. Omitting terminating resistors or adopting multi-point grounding is strictly prohibited to prevent communication abnormalities caused by signal reflection.

- Regularly check the module status indicator lights and connector tightness. If the communication light is off, priority should be given to troubleshooting the bus wiring, terminating resistors and the communication status of third-party devices.