Description

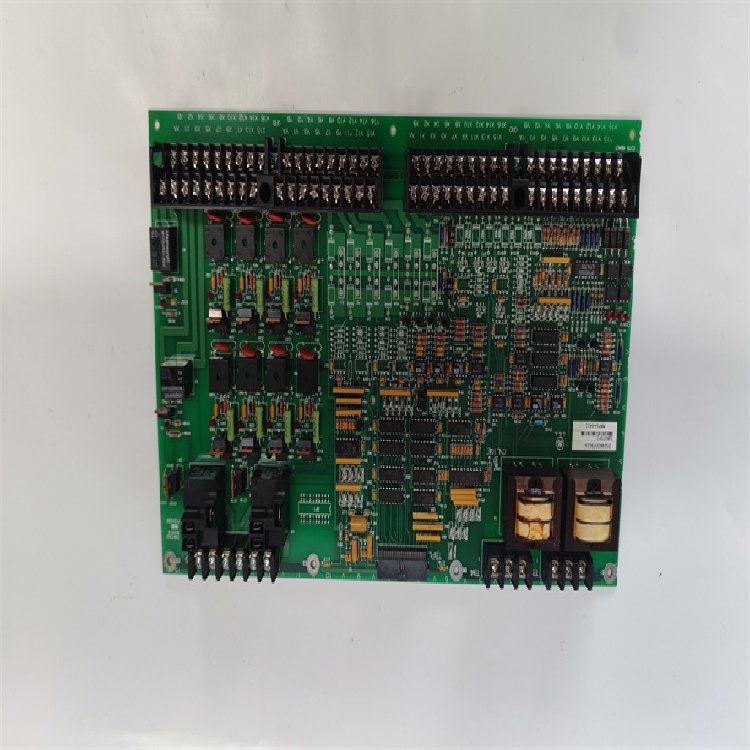

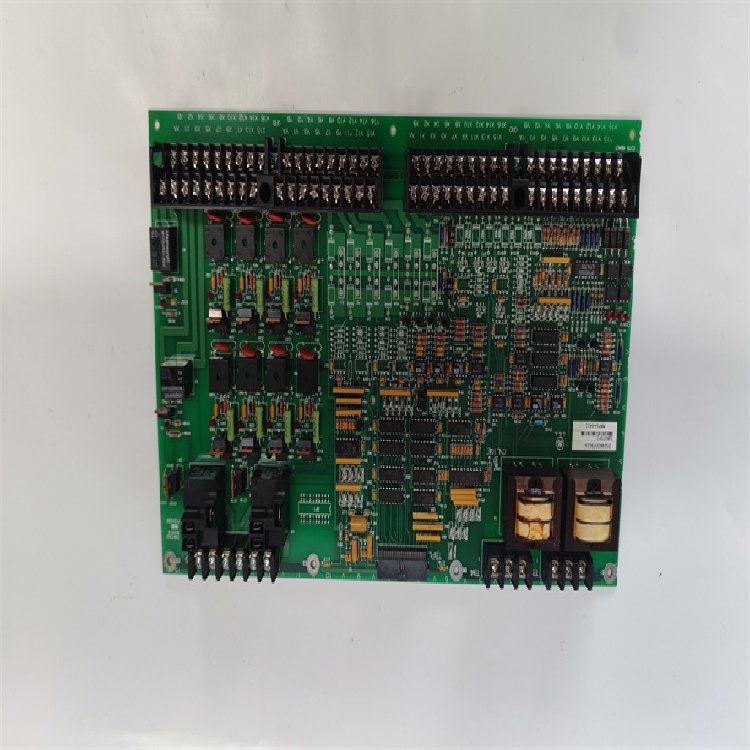

GE DS200VPBLG2A

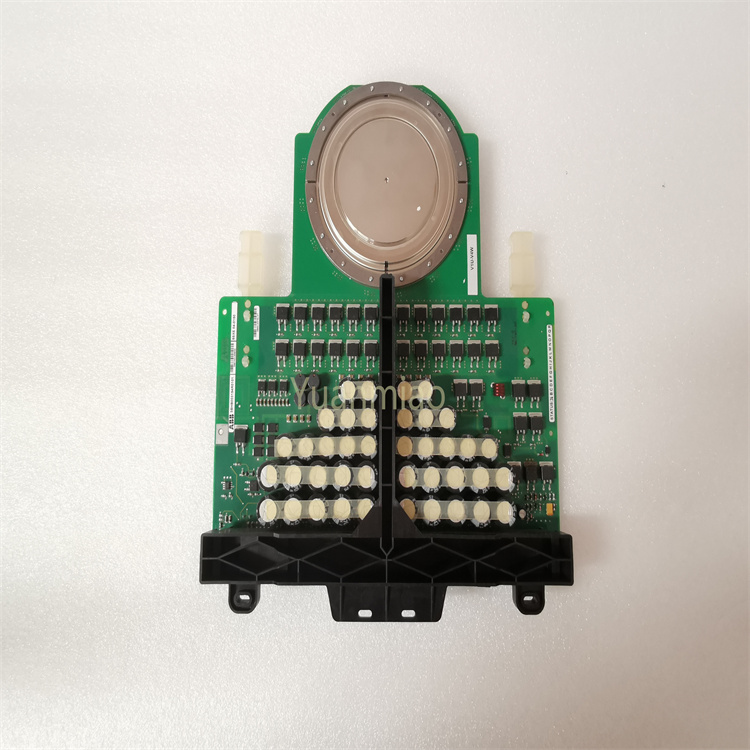

The GE DS200VPBLG2A is a high-performance industrial-grade analog input module, serving as a core signal acquisition component of the GE Mark VIe series Distributed Control System (DCS). It is positioned as a "High-Precision Multi-Type Analog Signal Acquisition Terminal for Large-Scale Industrial Equipment". Its core function is to perform high-precision acquisition, multi-dimensional signal conditioning, and high-speed digital conversion on various continuously changing key analog signals in industrial sites (such as temperature, pressure, flow rate, liquid level, vibration, rotational speed, and displacement). The accurately processed digital signals are uploaded to the controller module via a dual redundant backplane bus, providing highly reliable raw data support for closed-loop regulation of the control system, equipment status monitoring, performance optimization, and fault early warning. With its ultra-high acquisition precision, full-type signal compatibility, dual redundant architecture, and extreme environmental adaptability, this module is well-suited for key parameter monitoring needs of large rotating machinery (such as gas turbines, steam turbines, water turbines, and wind turbines) and complex process flows in fields including electric power, petrochemicals, metallurgy, and new energy. It is a core sensing unit of the GE Mark VIe control system for achieving refined control, safety interlocking, and intelligent operation and maintenance.

Its application scenarios accurately match the high-precision acquisition requirements for key analog signals in large-scale industrial systems:

- In the electric power generation field, as a core parameter acquisition module for gas turbine generator units, it synchronously collects 16 channels of key parameters, including gas turbine exhaust temperature (16-channel K-type thermocouple synchronous acquisition, accuracy ±0.1℃), combustion chamber pressure (4-20mA current signal, accuracy ±0.02% FS), shafting vibration (±10V voltage signal, accuracy ±0.1μm), and rotational speed (pulse frequency signal converted to analog, accuracy ±1rpm). After built-in cold-junction compensation, filtering, and isolation processing, the data is uploaded to the 531X series controller at a rate of 100Mbps, providing accurate data input for core control logics such as unit fuel regulation, load distribution, and vibration protection.

- In the petrochemical field, it is adapted for reaction process monitoring of large ethylene cracking units. It collects multi-type analog signals such as cracking furnace tube temperature (8-channel S-type thermocouples + 8-channel PT100 thermal resistors), reaction pressure, and feed flow rate. Through the module's group configuration function, centralized acquisition of different signal types is achieved. After linearization processing, the acquisition error is ≤0.05% FS, providing a reliable basis for closed-loop control of reaction temperature and process optimization.

- In the new energy field, it is used for status monitoring of large wind turbine generators. It collects analog signals such as main shaft bearing temperature, nacelle vibration, and generator stator temperature, and operates stably in outdoor environments with -40℃ low temperatures and strong sandstorms. The collected data is uploaded to the main control system in real time to realize unit health status assessment and fault early warning.

As a standard analog input module of the Mark VIe system, it supports seamless compatibility with controllers, redundant communication modules, and human-machine interfaces within the system. It realizes high-speed data transmission and redundant backup through a dual backplane bus, meeting the strict requirements of large-scale industrial units for "high precision, high reliability, no delay, and no loss" of key analog signals.

In terms of hardware architecture and system compatibility, the DS200VPBLG2A adopts a "main-standby dual-link" dual redundant hardware architecture. Its core consists of two independent signal conditioning units, 16 high-precision analog input channels, dual 24-bit A/D conversion modules, a redundant power management unit, and dual high-speed backplane interfaces. The two signal conditioning units synchronously receive on-site analog signals and complete processing procedures such as gain adjustment, filtering, and isolation in parallel. The main and standby A/D conversion modules synchronously perform digital conversion, and the redundant arbitration unit real-time compares the consistency of the two sets of converted data (the allowable error range can be set via configuration, default ±0.01% FS) to ensure the accuracy and reliability of the collected data.

The input channels adopt a "4-group independent configuration" design. Each group of 4 channels can be flexibly configured into more than 15 signal types (including 7 common types of thermocouples: K, J, T, E, R, S, B; thermal resistors: PT100, Cu50; current: 4-20mA, 0-20mA; voltage: 0-5V, 0-10V, ±5V, ±10V) through the DIP switches on the side of the module and configuration software, adapting to the signal output needs of sensors with different principles.

It has a built-in high-precision signal conditioning circuit, integrating a Programmable Gain Amplifier (PGA, gain range 1-1000x), an 8th-order low-pass filter, and a 2.5kVrms photoelectric isolation circuit. The gain can be automatically adjusted according to the signal amplitude, effectively suppressing common-mode interference and series-mode interference, with a Common-Mode Rejection Ratio (CMRR) of ≥120dB.

In terms of communication, it has two built-in high-speed redundant backplane bus interfaces, compatible with the proprietary GDS communication protocol of the GE Mark VIe system, enabling 100Mbps full-duplex data interaction with the controller. It supports 0-31 bit module address coding settings, facilitating address identification and data routing during multi-module networking.

Relying on industrial-grade reinforced design, the module uses wide-temperature-tolerant components (-40℃~70℃), an enhanced electromagnetic shielding enclosure (complying with IEC 61000-4-2/3/4/6 standards), and an anti-vibration plug-in structure. It can operate stably in industrial sites with high temperature, high humidity, strong electromagnetic interference, high vibration, and high dust, meeting the extreme reliability requirements of large-scale units for core acquisition modules.

The DS200VPBLG2A adopts a "main-standby dual-link" full-link redundancy architecture, establishing a full-link redundancy guarantee system covering "signal acquisition-conditioning-conversion-transmission-power supply". The module has two built-in independent signal conditioning units, which synchronously receive on-site analog signals and respectively perform gain adjustment, filtering and noise reduction, and isolation processing. It is equipped with dual 24-bit A/D conversion modules that synchronously convert the conditioned analog signals into digital signals. The redundant arbitration unit real-time compares the consistency of the two sets of converted data; when the data deviation exceeds the threshold (configurable), it automatically identifies the faulty channel and switches to the standby link.

When the main channel (e.g., Channel A) encounters faults such as signal conditioning circuit failure, A/D conversion abnormality, or bus transmission error, the standby channel (Channel B) takes over data acquisition and transmission without disturbance within ≤1ms, ensuring uninterrupted and undistorted collected data. The power supply system adopts dual independent DC 24V inputs and is equipped with dual power management chips. When the main power supply voltage fluctuates beyond ±15% or a power outage occurs, the standby power supply is automatically activated with a switching time of ≤1ms, ensuring stable operation of the module's core circuit. This full-link redundancy design enables the module to achieve the IEC 61508 SIL 2 standard in fault tolerance, fully meeting the "safety-level" requirements for key parameter acquisition in fields such as electric power and petrochemicals.

The module adopts a 16-channel group design (4 groups × 4 channels). Each group of channels can be independently configured with signal types via DIP switches and configuration software, supporting input of more than 15 types of analog signals including thermocouples, thermal resistors, current, and voltage. It can adapt to on-site sensors with different principles without replacing the module, greatly improving system integration flexibility.

For example, in a gas turbine control system, the first group of channels can be configured as K-type thermocouples (for exhaust temperature acquisition), the second group as PT100 thermal resistors (for lubricating oil temperature acquisition), the third group as 4-20mA current signals (for combustion chamber pressure acquisition), and the fourth group as ±10V voltage signals (for shaft vibration displacement acquisition), realizing centralized acquisition and unified management of multiple parameters.

Each group of channels is equipped with an independent Programmable Gain Amplifier (PGA) with a gain range of 1-1000x, which can be automatically adjusted according to the signal amplitude: when collecting mV-level weak vibration signals, it automatically switches to 1000x gain; when collecting 0-10V large-range pressure signals, it switches to 1x gain, ensuring optimal acquisition precision for signals of different amplitudes. The module has built-in various sensor linearization curves (such as thermocouple Degree tables and flow orifice differential pressure-flow curves), which can perform real-time linearization processing on non-linear signals and directly output standardized data, reducing the computational load of the controller and improving system response speed.

The module adopts a 24-bit high-precision A/D conversion chip (effective bits ≥22 bits), combined with an independent high-precision reference voltage source (accuracy ±0.001%) and a low-noise signal conditioning circuit, achieving industry-leading acquisition precision:

- The acquisition error of thermocouple signals within 0-1000℃ is ≤±0.1℃, which can accurately capture the 0.2℃ tiny fluctuation of gas turbine exhaust temperature;

- The error of thermal resistor signals within 0-200℃ is ≤±0.05℃, meeting the needs of precision temperature control scenarios such as lubricating oil temperature;

- The acquisition precision of current/voltage signals reaches ±0.02% FS, which is better than the average level of ±0.05% FS of similar products in the industry.

For thermocouple signals, the module has a built-in high-precision temperature sensor (accuracy ±0.05℃) to realize automatic cold-junction compensation, with a compensation range covering -40℃~70℃, effectively offsetting the impact of ambient temperature changes on thermocouple measurement.

To further improve data stability, the module is equipped with an 8th-order low-pass filter. The filter cutoff frequency can be flexibly set within the range of 1Hz-100Hz via configuration software, which can effectively filter out 50/60Hz power supply interference in industrial sites and high-frequency noise generated by equipment vibration. At a sampling rate of 1000Hz, the long-term acquisition stability error of the module is ≤±0.01% FS/24 hours, meeting the high-precision monitoring needs of large-scale units for long-term continuous operation.

The module adopts a triple anti-interference design of "hardware isolation + electromagnetic shielding + signal filtering", enabling stable operation in complex industrial environments with strong electromagnetic interference, high dust, and high humidity.

In terms of hardware isolation, each input channel adopts photoelectric isolation technology with an isolation voltage of ≥2.5kVrms, effectively blocking common-mode interference and ground loop interference between on-site sensors and the module's core circuit. The module enclosure is made of high-strength aluminum alloy with an electromagnetic shielding coating sprayed on the surface, achieving a shielding effectiveness of ≥60dB and complying with the IEC 61000-4-3 RF radiation immunity standard (10V/m), which can resist strong electromagnetic radiation interference generated by equipment such as generators and frequency converters.

In terms of signal processing, in addition to the 8th-order low-pass filter, the module is also equipped with a high-performance common-mode suppression circuit, with a Common-Mode Rejection Ratio (CMRR) of ≥120dB@50/60Hz, which can effectively suppress common-mode interference between power lines and signal lines. For example, when collecting signals near a high-voltage motor control cabinet, it can effectively offset the common-mode voltage interference generated by high-voltage equipment.

The wiring terminals adopt a Phoenix plug-in design, featuring anti-loosening, anti-misplug, and IP20 waterproof and dustproof functions, with a contact resistance of ≤10mΩ, ensuring wiring reliability in long-term vibration environments. The vibration resistance level meets the 10g acceleration requirement of the IEC 60068-2-6 standard. The multiple anti-interference design allows the module to be directly applied to high-interference industrial scenarios such as power generation, metallurgy, and petrochemicals without additional anti-interference accessories

![]()