Description

I. Technical Parameters

1. Electrical Parameters

- Power Supply Voltage:

DC 24V ±10% or AC 100-240V (depending on the module type). - Processor Performance:

32-bit or 64-bit microprocessor with a clock frequency ranging from 100MHz to 1GHz. - Memory Configuration:

- Flash/EEPROM: 512KB–16MB (for program storage).

- RAM: 256KB–8MB (operational memory).

- Communication Interfaces:

Supports industrial bus protocols (e.g., PROFINET, EtherNet/IP, Modbus RTU/TCP).

May integrate RS-232/RS-485 serial ports or USB interfaces. - I/O Characteristics (for I/O modules):

- Digital Input/Output: 16/16 points (typical), supporting 24V DC signals.

- Analog Input/Output: 4-20mA or 0-10V (accuracy ±0.1%–±0.5%).

2. Mechanical and Environmental Parameters

- Package Form:

Standard rail mounting (e.g., DIN Rail), with dimensions of approximately 100mm×100mm×50mm (compact design). - Operating Temperature:

-25°C ~ +60°C (industrial grade, supporting wide temperature ranges). - Protection Level:

IP20 (indoor dust protection, preventing solid foreign objects). - Anti-Interference Capability:

Complies with EMC standards (e.g., EN 61000-6-2/3), resistant to electromagnetic interference (EMI) and radio-frequency interference (RFI).

3. Functional Features

- Real-Time Control:

Supports high-speed counters and pulse output (PTO/PWM), suitable for motion control scenarios. - Safety Functions:

May integrate fail-safe modules (e.g., SIL2/SIL3 compliance with IEC 61508 standards). - Firmware Upgrade:

Supports online updates via USB or Ethernet (requires dedicated software such as ABB’s AC 800M or Automation Builder).

II. Product Types and Application Scenarios

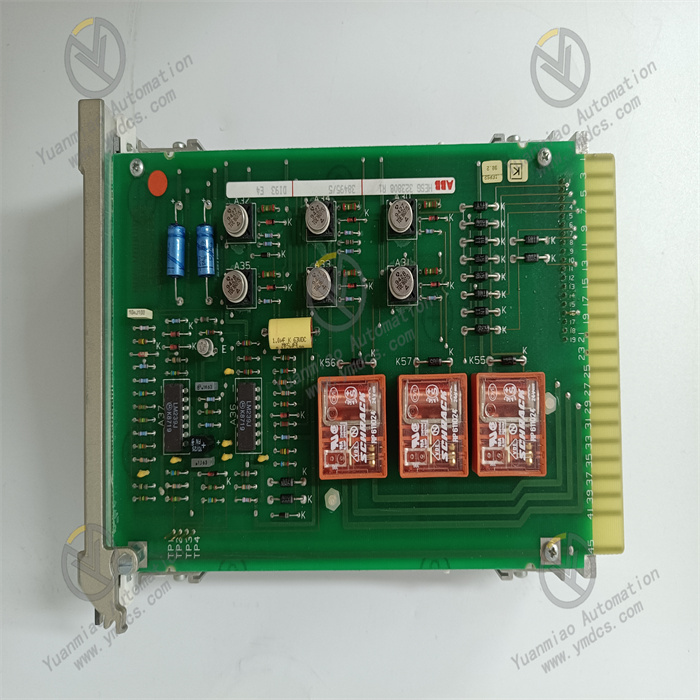

1. Power Electronics Modules (Inverter/Converter Components)

- Common Scenarios:

Used in ABB’s ACS800 inverter series or ACQ580 series, where some power modules, drive boards, or control units may follow similar numbering rules. Examples include: - Motor drive systems (industrial fans, pumps, compressors, etc.).

- Renewable energy fields (e.g., wind power converters, sub-modules of photovoltaic inverters).

- Marine electric propulsion systems or rail transit traction converters.

- Possible Functions:

Serves as an IGBT power module or drive circuit board, responsible for power conversion or signal processing.

Supports high voltage (e.g., DC 690V) and high current (hundreds of amperes) scenarios, with switching frequencies exceeding 20kHz.

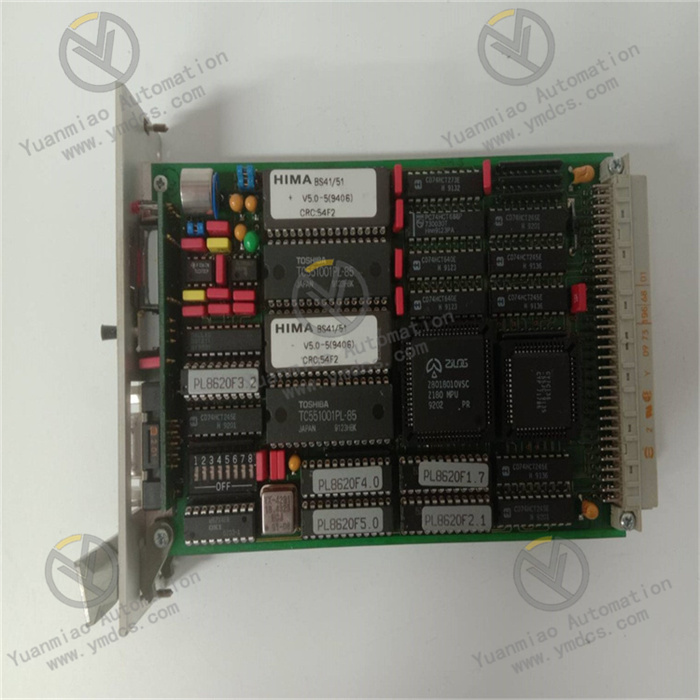

2. Industrial Control Modules (PLC/DCS Components)

- Common Scenarios:

Used in ABB’s AC 800M PLC system or ProConOS control system, potentially including communication modules, I/O modules, or processor modules. Examples include: - Process automation (chemical, metallurgical, paper-making industries, etc.).

- Distributed control systems (DCS) in large factories for data acquisition and logical control.

- Possible Functions:

Supports field bus protocols (e.g., PROFIBUS, EtherCAT) as a master or slave module.

Features analog/digital input/output (AI/AO/DI/DO), high-speed counting, temperature control, and other functions.

Operation Guide for ABB UFC760BE145 3BHE004573R0145

Signal Verification

- Verify Signals Using Virtual Channels:

- Right-click the virtual channel to be verified and select "Test".

- In "Channel Name", select the channel to be verified.

- Click "Close" after completing channel verification.

- Verify Signals Using Channel Strings:

- Click the "+" next to "Devices and Interfaces". For information on formatting channel strings, refer to the relevant appendix on "Using SCXI Channel Strings with Legacy NI-DAQ (Legacy) 7.0 or Higher".

Common Faults and Corresponding Solutions

- Power Supply Faults:

- Possible Causes: Abnormal input voltage, loose power cables or blown fuses, damaged internal power modules.

- Solutions: Measure input voltage to ensure it is within the rated range; check wiring and replace fuses; contact after-sales service for repairs.

- Communication Faults:

- Possible Causes: Mismatched protocol parameters, damaged communication cables, faulty interface chips, or incompatible firmware versions.

- Solutions: Verify parameters such as baud rate and slave address; replace cables and test communication waveforms; update firmware.

- I/O Signal Anomalies:

- Possible Causes: Input signals out of range, output load short circuits, poor terminal contact, or circuit aging.

- Solutions: Measure signal values and troubleshoot front-end equipment; disconnect loads for testing and check terminal connections.

- Overheating or Environmental Faults:

- Possible Causes: Poor heat dissipation, faulty fans, excessive environmental humidity/dust.

- Solutions: Clean cooling vents and replace fans; control environmental temperature/humidity and perform regular maintenance.

- Hardware Faults:

- Possible Causes: Damaged memory, chip logic errors, damage from static electricity or overvoltage.

- Solutions: Attempt to restore factory settings or reflash firmware; replace modules and take anti-static measures during operation.