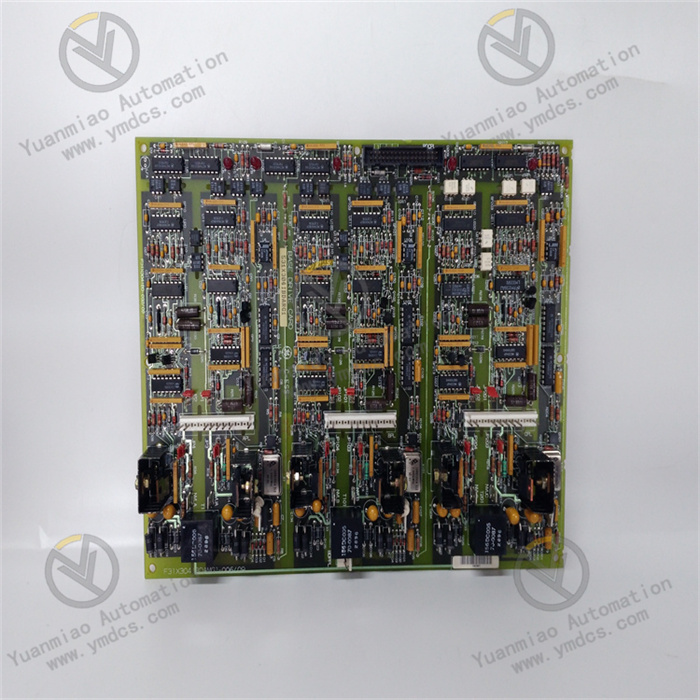

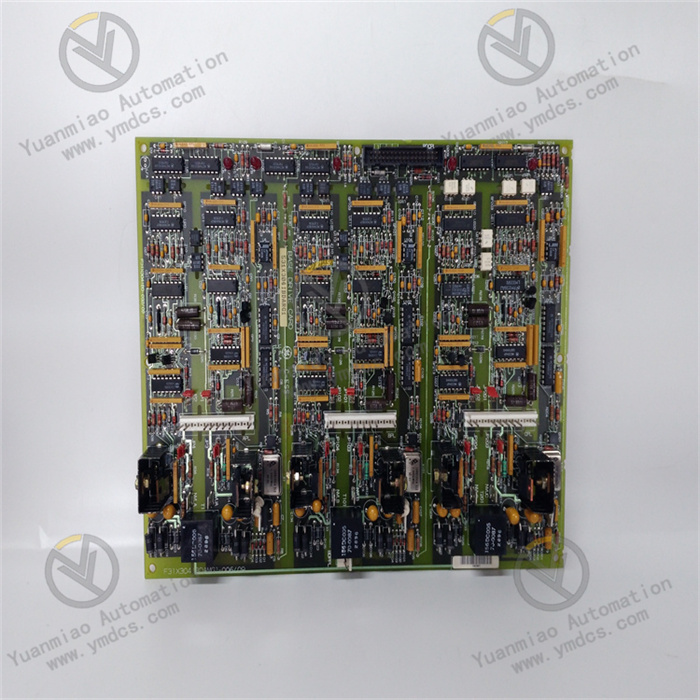

Description

Abaco Systems VME-7807RC-410000

Abaco Systems VME-7807RC-410000 350-930078074-410000 G (hereinafter referred to as VME-7807RC) is a VME bus embedded computing module positioned as the "core unit for high-reliability real-time data processing in harsh environments". It is widely used in fields with extremely high requirements for equipment stability, real-time performance, and resistance to harsh environments, such as aerospace, defense electronics, industrial automation, and energy exploration. As a core computing node in the VME bus architecture, this module undertakes core tasks including real-time data acquisition, complex algorithm operation, multi-device collaborative control, and key task scheduling, providing strong hardware computing support for critical scenarios such as radar signal processing, UAV flight control systems, and industrial process closed-loop control.

The VME-7807RC is highly compliant with the VMEbus Rev. C.1 bus specification. It adopts a high-performance multi-core processor architecture, an enhanced heat dissipation design, and a multi-layer anti-interference protection mechanism. It can be directly connected to a standard VME rack, enabling seamless collaboration with various VME bus I/O modules and storage modules without the need for additional adapter modules. Its core advantages lie in strong multi-core parallel processing capabilities, fast real-time response speed, excellent environmental adaptability, and outstanding bus compatibility. It can be adapted to various application scenarios ranging from small and medium-sized embedded systems to large-scale distributed real-time computing platforms. It can operate stably for a long time under working conditions such as a wide temperature range of -40℃ to 85℃, strong vibration, high impact, and strong electromagnetic interference, meeting the strict requirements for equipment reliability and performance in military-grade (such as GJB) and high-end industrial-grade applications (such as MIL-STD).

Equipped with the Intel Core i7-6820EQ quad-core eight-thread processor (main frequency 2.8GHz, maximum turbo frequency 3.5GHz) and combined with 8MB high-speed cache, it enables efficient parallel processing of multiple tasks. The processor scheduling mechanism optimized for real-time computing scenarios can effectively reduce task switching latency, with a core task response time of ≤10μs. The 16GB DDR4 ECC memory supports error checking and correction functions, which can automatically repair single-bit errors and detect double-bit errors to avoid system crashes caused by memory errors. With a memory bandwidth of 25.6GB/s, it ensures high-speed transmission and caching of large-scale data (such as radar echo data and industrial sensor array data). The combination of on-board eMMC flash memory and SATA/NVMe storage interfaces can meet storage needs in different scenarios; after expanding the NVMe interface, the storage read-write speed can reach 2GB/s, providing support for local caching of massive real-time data.

It strictly complies with the VMEbus Rev. C.1 specification and VME64x expansion standard, and can be directly embedded into a standard 6U VME rack. Mechanical fixation and electrical connection are realized via VME bus connectors, and no additional adapter components are required during installation, enabling physical installation and bus connection within 15 minutes. When used as a VME bus master device, it supports 32-bit/64-bit address space access, with a maximum bus data transmission rate of 160MB/s in block transfer mode, allowing efficient scheduling of peripheral devices such as I/O modules and acquisition modules on the bus. When used as a slave device, it can quickly respond to instructions from the main controller, with a data reception latency of ≤500ns. It is compatible with mainstream VME bus arbitration mechanisms, supporting priority arbitration (to ensure priority transmission of key task data) and fair arbitration (to prevent a single device from monopolizing the bus). It also has bus error detection, fault isolation, and automatic recovery functions; when an abnormality occurs on the bus, it can switch to the backup communication path within 1ms to ensure the continuity of system communication.

It integrates diverse expansion interfaces to meet the customized needs of different industry applications: 2 Gigabit Ethernet interfaces support IEEE 1588 PTP precise clock synchronization, with a clock synchronization accuracy of ±10ns, enabling time coordination of multiple nodes in a distributed system; 4 multi-protocol serial ports support RS-232/422/485 mode switching, adapting to low-speed peripheral devices such as industrial sensors and serial port devices; via the PCIe 3.0 interface, it can be expanded with Abaco dedicated aerospace bus cards (such as ARINC 429 and MIL-STD-1553B) to directly access the bus network in the aerospace field without the need for additional protocol conversion modules. 1 PCIe 3.0 x16 interface supports the expansion of high-performance graphics cards or data acquisition cards, enabling complex functions such as real-time image processing and high-speed signal acquisition. The interface layout adopts a modular design, and each group of interfaces is equipped with independent signal isolation and protection circuits to improve the working stability of the interfaces.

It is designed for environmental adaptability in accordance with the MIL-STD-810G military standard. Core components are all industrial-grade wide-temperature products, with an operating temperature range covering -40℃ to 85℃, allowing normal operation in extreme environments such as high-temperature deserts, low-temperature plateaus, and humid and hot oceans. The combined heat dissipation structure of all-aluminum heat dissipation fins and embedded heat pipes greatly improves heat dissipation efficiency; when operating at full load in a high-temperature environment of 85℃, the processor temperature can be controlled within 95℃. Combined with the intelligent fan speed control system, the fan stops running to save energy in low-temperature environments and automatically increases speed to enhance heat dissipation in high-temperature environments, balancing heat dissipation performance and low-noise requirements. The vibration and shock resistance design is realized through structural optimization: components inside the module adopt a reinforced welding process, and the bus connectors use a locking design, which can resist 3g continuous vibration and 50g peak shock, meeting the installation requirements of mobile platforms such as vehicle-mounted, ship-mounted, and airborne systems.

It adopts a dual-channel redundant power supply design, with the +5V and +12V power supply circuits independently isolated. When one power supply fails, the other can automatically switch to supply power within 2ms to ensure uninterrupted operation of the module. The power supply circuit integrates four layers of protection: overvoltage, overcurrent, undervoltage, and reverse connection. When the input voltage is abnormal or the polarity is reversed, it immediately cuts off the power supply circuit and triggers an alarm to avoid damage to the internal circuits of the module. It supports the VME bus hot-swapping function (needing to be used with a dedicated backplane), enabling replacement and maintenance of the module without shutting down the system, thereby reducing system downtime. The module-level health status monitoring function can collect key parameters in real time, such as processor temperature, memory usage, power supply voltage, and fan speed. When the parameters exceed the threshold, it outputs an alarm signal via the bus and records fault logs, facilitating engineers to predict faults in advance and carry out maintenance.

It is compatible with mainstream operating systems such as Windows, Linux, and VxWorks. The adaptation and optimization for the VxWorks 7 real-time operating system reduce the system scheduling latency to ≤1ms, meeting the needs of high-real-time applications (such as industrial closed-loop control and UAV flight control). Abaco provides a complete Device Driver Package, covering drivers for all interfaces and peripheral devices, supporting plug-and-play and greatly shortening the development cycle. To meet the needs of scientific research and engineering development, it provides interface libraries for development tools such as LabVIEW and MATLAB, allowing engineers to quickly realize data acquisition, algorithm verification, and system control through graphical programming. In addition, Abaco also provides customized software development services, which can optimize system configurations and drivers according to the specific needs of users to ensure seamless integration of the module with the user's existing system.

![]()