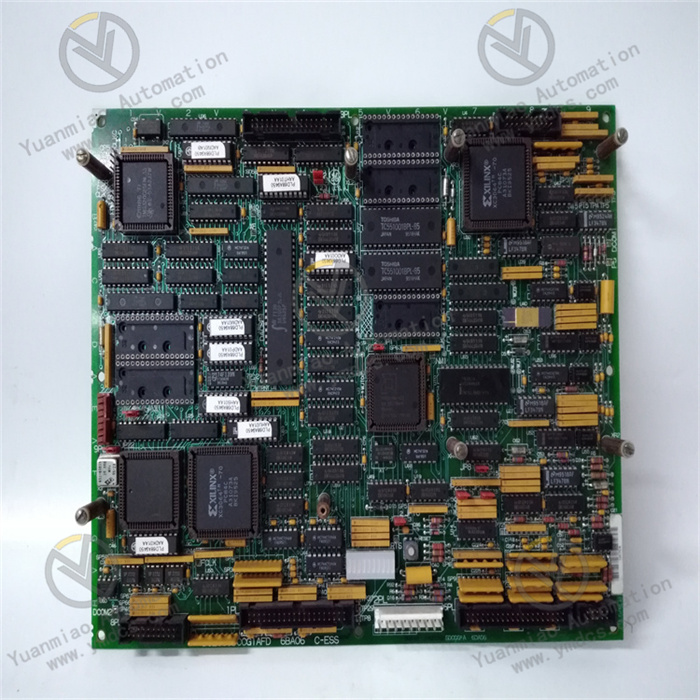

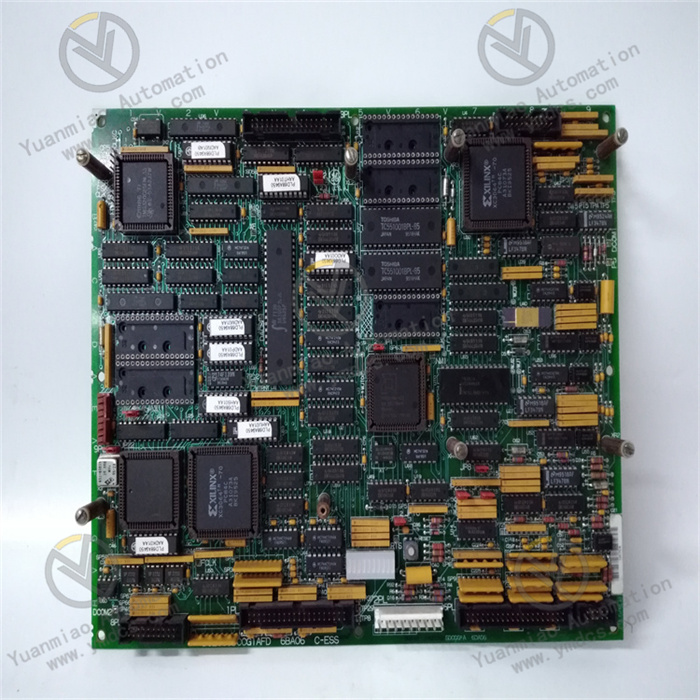

Description

GE DS200CDBAG1BBB

GE DS200CDBAG1BBB is an excitation control interface module, specifically positioned as a "digital control and signal interaction unit for steam turbine generator excitation systems". It focuses on addressing issues related to precise control, condition monitoring, and safety interlocking of steam turbine generator excitation systems in power generation scenarios such as thermal power, hydropower, and nuclear power. It provides critical hardware support and a signal interaction bridge for generator voltage regulation, reactive power control, and fault protection.

Deeply integrated into the Mark VI control system architecture, this module adopts high-reliability digital signal processing technology, strong electrical and weak electrical isolation design, and dedicated interface circuits for excitation systems. It undertakes core tasks including excitation regulator command parsing, excitation power unit status collection, trigger pulse output, fault signal processing, and communication with the main controller. This ensures the stability, accuracy, and safety of excitation control in harsh power generation environments characterized by high voltage, strong electromagnetic interference, and wide load fluctuations.

As a key interface hub of the Mark VI excitation control system, the DS200CDBAG1BBB features core advantages such as dedicated excitation signal adaptation, high-precision trigger control, multiple safety protections, and deep compatibility with excitation systems. It can directly connect to key excitation system equipment (e.g., excitation power cabinets, de-excitation cabinets, potential transformers (PT), current transformers (CT)) without additional adaptation modules, enabling full-link closed-loop management of excitation control signals covering "collection-processing-output-feedback".

It is widely used in various steam turbine generator excitation systems, including static excitation systems for 300MW and 600MW thermal power units, self-shunt excitation systems for hydropower units, and excitation control scenarios for nuclear power auxiliary generators. The module possesses core characteristics such as seamless collaboration with the Mark VI system, full isolation between strong and weak electricity, rapid response to excitation faults, high-precision trigger pulse output, and intelligent diagnosis. It can adapt to an operating environment of -20℃ to 65℃, meet strict electromagnetic compatibility requirements and high-voltage isolation standards, and fully satisfy the rigorous demands of the power generation industry for excitation control reliability, accuracy, and safety.

Adopting the Mark VI system’s dedicated VME bus architecture, it achieves full-dimensional seamless integration with the main controller, ToolboxST configuration software, and HMI operation interface. The data interaction mechanism is optimized for excitation control scenarios to ensure collaborative consistency between excitation control and the unit’s main control.

The module can be directly embedded in the Mark VI standard VME rack, with mechanical fixation and electrical connection completed via a dedicated bus connector—no additional adaptation modules or signal converters are required, and physical installation and system access can be completed in just 30 minutes. After accessing the system, the ToolboxST configuration software automatically identifies the module ID, interface configuration, and hardware version. Engineers can configure excitation control parameters (e.g., PID regulation coefficients, trigger pulse parameters, protection thresholds) via a graphical interface, supporting online debugging and offline simulation of excitation control logic without manual writing of underlying driver programs.

The data transmission between the module and the main controller adopts a synchronous communication mechanism: the upload cycle of excitation status data is ≤10ms, and the delay of control command issuance is ≤5ms. This ensures rapid response and regulation when the generator voltage fluctuates. For example, when the unit load changes suddenly causing generator terminal voltage fluctuations, the module can complete the closed-loop process of "signal collection-command issuance-regulation execution" within 15ms.

It has the capability to adapt to all types of signals in excitation systems, directly accessing key analog signals (e.g., excitation current, excitation voltage, generator terminal voltage) and digital signals (e.g., excitation cabinet status, fault signals), while outputting high-precision excitation regulation commands and pulse trigger signals to achieve precise full-link management of excitation control.

The analog input channels are optimized for the signal characteristics of excitation systems: the 4-20mA channel has an input impedance of ≤250Ω, allowing direct access to secondary signals of excitation current transformers (CT) and potential transformers (PT) without additional signal conditioners; the 0-10V channel has an input impedance of ≥100kΩ, adapting to the high-precision collection needs of generator terminal voltage feedback with a collection accuracy of ±0.05% FS to ensure the accuracy of basic data for voltage regulation.

The digital input channels support 24V DC dry/wet contact signals, enabling access to status signals such as "operation ready", "overcurrent fault", and "de-excitation completion" from the excitation power cabinet. The input response time is ≤1ms to ensure rapid capture of fault signals; it also has a signal filtering function (adjustable 0.1-10ms) to filter out false signals caused by strong electromagnetic interference in the excitation system.

The analog output channels have an output accuracy of ±0.1% FS, which can output excitation regulation commands to control the conduction angle of the excitation power unit and reactive power setpoint signals to achieve precise regulation of reactive power.

Equipped with 4 high-precision pulse trigger output channels, specifically designed for driving thyristors or IGBTs in excitation power units, it features adjustable pulse width, high synchronization accuracy, and strong anti-interference capabilities to ensure the accuracy and stability of excitation regulation.

The pulse trigger output adopts digital phase-locked loop technology with a synchronization accuracy of ±1μs, enabling precise tracking of grid frequency changes. Even when the grid frequency fluctuates by ±0.5Hz, it can maintain the stability of the trigger phase to avoid excitation current fluctuations caused by frequency variations.

The pulse width can be flexibly configured via software within the range of 50-200μs to adapt to the triggering needs of different types of thyristors or IGBTs. For example, a 200μs wide pulse can be set for high-power thyristors to ensure reliable conduction.

The pulse output adopts an optoelectronic isolation design with an isolation voltage of 2500V AC, which can effectively resist high-voltage interference from the excitation power unit and prevent interference signals from entering the control circuit and damaging the module.

The module has a built-in pulse loss detection function: if no trigger pulse feedback is detected for 3 consecutive cycles, it triggers a fault alarm and switches to the backup trigger circuit within 5ms, ensuring the continuity of excitation regulation—this is particularly suitable for the redundant design of excitation systems in large units.

Integrating multiple dedicated safety protection functions for excitation systems, it covers key fault scenarios such as overcurrent, overvoltage, pulse loss, and power fault. Combined with an emergency de-excitation rapid response mechanism, it ensures the safe operation of the excitation system and rapid handling in case of faults.

The module has a built-in excitation overcurrent protection logic: by comparing the real-time collected excitation current signal with the preset threshold, if the current exceeds 110% of the threshold, it outputs an overcurrent protection signal within 5ms to control the excitation power unit and limit the current; if the current exceeds 150% of the threshold, it immediately outputs an emergency de-excitation signal to trigger the de-excitation cabinet to quickly cut off the excitation circuit and avoid generator damage.

The overvoltage protection function monitors the generator terminal voltage and excitation voltage: if the voltage exceeds 115% of the threshold, it outputs a regulation command to reduce the excitation voltage; if the voltage exceeds 120% of the threshold, it triggers emergency de-excitation.

The pulse loss protection function monitors the output status of trigger pulses in real time: if pulse loss is detected, it immediately switches to the backup trigger channel and issues an alarm to ensure uninterrupted excitation regulation.

In the event of a dual-channel power supply failure, the power fault protection function can trigger the activation of the backup power supply (response time ≤1ms) while saving the current excitation control parameters to avoid abnormal regulation after restart due to parameter loss.

Adopting a multiple isolation design with full isolation between strong and weak electricity and inter-channel isolation, combined with electromagnetic compatibility optimization measures, it can operate stably in harsh excitation system environments with high voltage and strong electromagnetic interference, ensuring the reliability of control signals.

A dual isolation design (optoelectronic isolation and transformer isolation) is adopted between the module’s strong electrical interfaces (pulse trigger output, potential transformer input) and weak electrical interfaces (digital and analog control signals), with an isolation voltage of 2500V AC. This effectively blocks electromagnetic interference generated by high voltage and large current in the excitation power unit from entering the control circuit.

The isolation voltage between analog input channels is 1000V AC, and the isolation voltage between digital input and output channels is 1000V AC, avoiding signal crosstalk between different channels. For example, interference in the excitation current collection channel will not affect the accuracy of the generator terminal voltage collection channel.

With a common mode rejection ratio of ≥120dB and a differential mode rejection ratio of ≥90dB, it can effectively suppress high-order harmonic interference caused by thyristor commutation in the excitation system and common mode interference caused by grid fluctuations.

The module housing is made of die-cast aluminum alloy with an anti-static coating, and the internal circuit board adopts a grounded shielding design to further enhance anti-interference capabilities. It complies with the IEC 61000-4 series of electromagnetic compatibility standards.

Integrating full-dimensional intelligent diagnosis functions at the module, channel, and function levels, it has capabilities such as rapid fault localization, fault log storage, and fault self-recovery, significantly reducing the difficulty and cost of excitation system operation and maintenance.

The module is equipped with 8 status indicator lights, including "Power Normal", "Operation Ready", "Communication Normal", "Pulse Normal", "Overcurrent Fault", "Overvoltage Fault", "Pulse Loss", and "De-excitation Status". The on/off and blinking of the indicator lights enable quick judgment of fault types and scopes.

Channel-level diagnosis supports detection of analog channel disconnection, short circuit, signal over-range, digital channel signal abnormalities, and pulse output channel faults; function-level diagnosis supports detection of PID regulation logic abnormalities, synchronization signal loss, and phase-locked loop faults, with a fault response time of ≤5ms.

When a fault occurs, the module outputs an alarm signal via dry contacts to link with on-site audible and visual alarms, while uploading fault information (fault type, occurrence time, parameters at the time of fault) to the Mark VI main controller for storage in the fault log (which can store 100 timestamped records).

Engineers can view fault logs and monitor parameters and waveforms of each channel online via the ToolboxST software, enabling fault localization without on-site disassembly of the module. Minor faults (e.g., pulse abnormalities caused by transient interference) can be automatically restored via the module’s self-recovery function, reducing manual intervention.

Adopting industrial-grade component selection and reliability design, combined with efficient heat dissipation and protection measures, it can operate stably in harsh power generation environments with high temperature, high vibration, and strong electromagnetic interference, ensuring the long-term reliability of the excitation system.

The core components of the module (e.g., processor, AD converter, optoelectronic isolator) are all industrial-grade wide-temperature products, with an operating temperature range of -20℃ to 65℃, adapting to temperature fluctuations in power plant control rooms or excitation cabinets. It also has humidity adaptability, enabling normal operation in an environment with 5%-95% relative humidity (no condensation).

With a vibration resistance rating of 1.5g (10-2000Hz) and a shock resistance rating of 20g, the overall rigidity of the module is enhanced through structural optimization, allowing installation in excitation control cabinets near steam turbine generators to resist vibration effects caused by unit operation.

The heat dissipation design adopts a "high-density heat sink + natural convection" approach: core heating components (e.g., pulse trigger chips, power tubes) are closely attached to the heat sink, and the housing is designed with heat dissipation fins to enhance heat exchange. When operating at full load in a high-temperature environment of 65℃, the core temperature of the module remains ≤80℃—no additional cooling fans are required, avoiding module damage caused by fan faults.

With a mean time between failures (MTBF) of ≥500,000 hours and a service life of ≥15 years, it fully meets the long-term reliability requirements of the power generation industry for equipment.

![]()