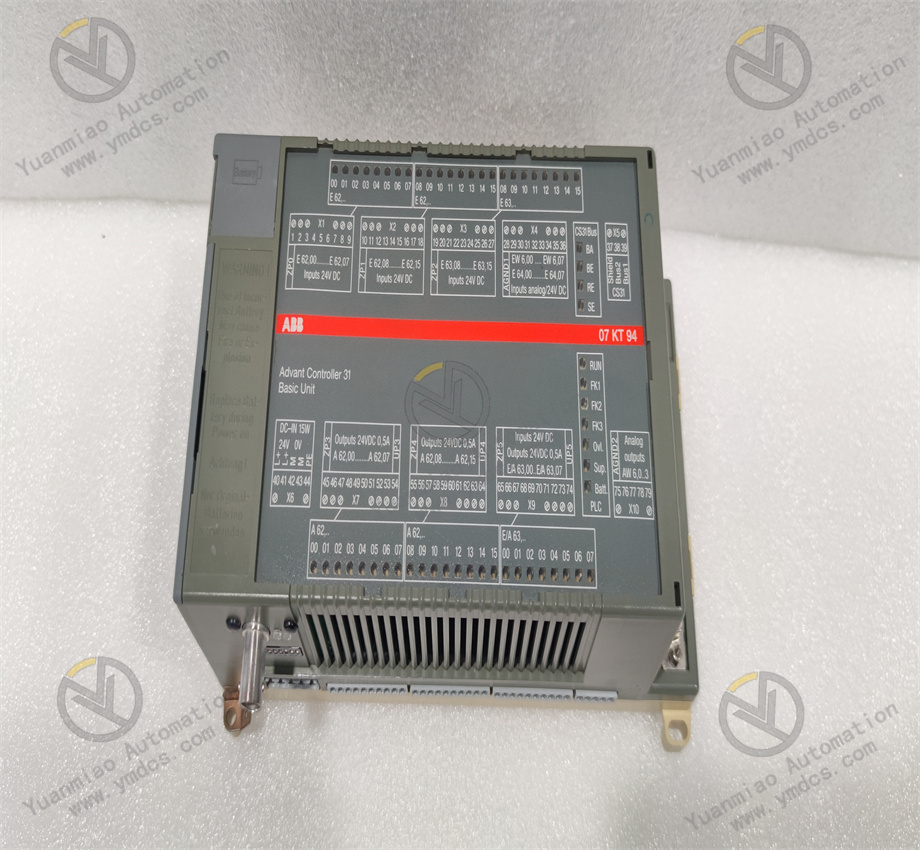

Description

Basic Information Product Type: It belongs to ABB's standard drive products and is a wall-mounted unit. Applicable Motor Power: It is 75kW for general applications and 55kW for heavy-duty applications. Rated Output Current: It is 157A for general applications and 124A for heavy-duty applications. Power Supply Voltage: Three-phase AC380V - 480V, with a frequency of 50/60Hz. Protection Level: IP21 (when there is no control panel). Product Features Harmonic Suppression: The variable inductance reactor can greatly reduce harmonics. Electromagnetic Compatibility: It is standardly equipped with a built-in electromagnetic compatibility filter of C2 level (for environment class 1). Braking Function: A braking chopper below 11 kilowatts is standard. Complete Certifications: It has passed UL, cUL, CE, C-Tick and GOST R certifications and complies with the RoHS standard. Flexible Communication: It has a flexible bus system, with a built-in Modbus device and many internally installed bus adapters.

Application Scenarios Fans and Pumps: It can adjust the speed and torque of the motor according to actual needs, achieving energy conservation and consumption reduction, and at the same time reducing the operation noise of the equipment. Mechanical Manufacturing: It is used to drive various equipment such as machine tools, punching machines, and shearing machines, achieving precise speed and position control, and improving machining accuracy and production efficiency. Chemical and Building Materials: It can be used to drive equipment such as mixers and conveyors, achieving precise control of material conveying and mixing, and improving product quality and production efficiency. Textile and Dyeing: It is used to drive equipment such as winding machines and dyeing machines, achieving precise control of speed and tension, and improving product consistency and stability.

Some common faults may occur during the use of the frequency converter ABB ACS550-01-157A-4. The following are these faults, possible causes and corresponding solutions: 1. Overcurrent Fault Possible Causes: The motor load is too large, such as mechanical jamming, excessive load inertia, etc.; the motor cable is short-circuited or has a grounding fault; the output side of the frequency converter is short-circuited; the parameters of the frequency converter are set unreasonably, such as incorrect setting of the motor rated current, too short acceleration time, etc. Solutions: Check the motor and the load, eliminate mechanical faults, and ensure the normal operation of the load; check the motor cable and repair the short-circuit or grounding fault; check the output side of the frequency converter and eliminate the short-circuit situation; check and correctly set the parameters of the frequency converter, appropriately increase the acceleration time, and ensure that the setting of the motor rated current is consistent with the actual parameters of the motor. 2. Overvoltage Fault Possible Causes: The power supply voltage is too high, exceeding the rated voltage range of the frequency converter; when the motor is in the regenerative braking state, the braking resistor is not connected or the resistance value is incorrect; the deceleration time is too short, and the feedback energy of the motor is too large. Solutions: Check the power supply voltage and ensure that it is within the rated voltage range of the frequency converter. If the voltage is too high, the power supply needs to be adjusted or a suitable voltage reduction device should be used; check whether the connection of the braking resistor is correct, measure whether the resistance value meets the requirements, and replace the resistor in time if it is damaged; appropriately increase the deceleration time to allow the feedback energy of the motor to be fully released and avoid the excessive DC bus voltage. 3. Undervoltage Fault Possible Causes: The power supply voltage is too low, such as grid faults, too small or too long power line diameter resulting in excessive voltage drop; the fuse of the frequency converter is blown; the rectifier bridge fails. Solutions: Check the power supply voltage. If the voltage is too low, the grid problem needs to be investigated or a suitable power line should be replaced; check the fuse. If it is blown, the cause needs to be identified and the fuse should be replaced; check the rectifier bridge and replace the rectifier bridge module in time if it is damaged. 4. Overheating Fault Possible Causes: Poor ventilation of the frequency converter, such as a damaged fan or blocked air duct; the ambient temperature is too high; the load is too large, resulting in the frequency converter operating under overload for a long time; faults of internal components of the frequency converter, such as poor heat dissipation effect of the heat sink, damaged power module, etc. Solutions: Check whether the fan of the frequency converter is operating normally, clean the air duct, and ensure good ventilation; improve the installation environment of the frequency converter, reduce the ambient temperature, and install an air conditioner or a heat dissipation device if necessary; check the load situation and avoid long-term overload operation; check the internal components of the frequency converter, such as whether there is dust accumulation on the heat sink and whether the power module is damaged, and clean or replace them in time if there are problems. 5. Grounding Fault Possible Causes: The motor or the motor cable is grounded; there is a fault in the internal grounding detection circuit of the frequency converter. Solutions: Check the motor and the motor cable, eliminate the grounding fault, and ensure that the motor and the cable have good insulation; check the internal grounding detection circuit of the frequency converter, and contact professional maintenance personnel for repair if there is a fault. 6. Communication Fault Possible Causes: The communication cable is incorrectly connected or damaged; the communication parameters are incorrectly set, such as baud rate, address, etc.; the communication equipment (such as PLC, upper computer) fails; interference problems, such as electromagnetic interference, signal attenuation, etc. Solutions: Check the connection of the communication cable, ensure that the connection is correct and firm, and replace the cable in time if it is damaged; check and correctly set the communication parameters to ensure consistency with the communication equipment; check the communication equipment and eliminate the equipment failure; take anti-interference measures, such as using shielded cables, reasonable wiring, installing filters, etc., to reduce the impact of interference on communication.