Description

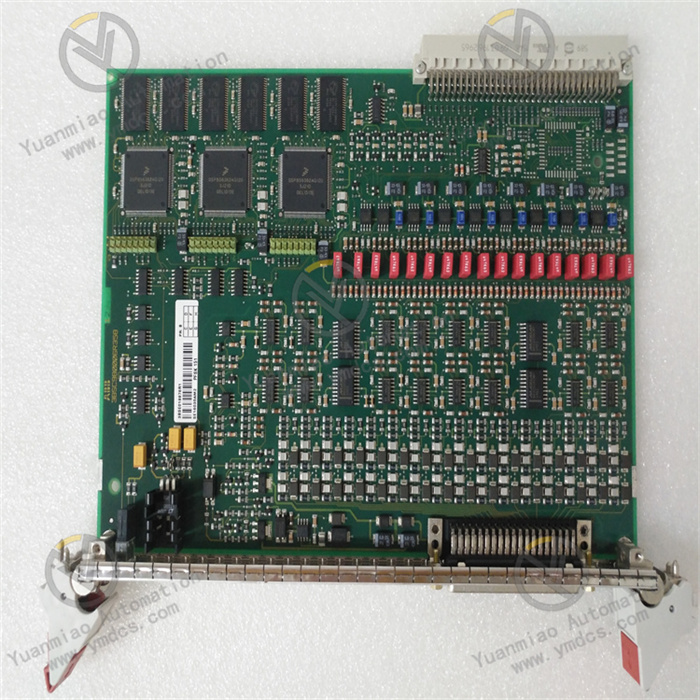

GE DS200FGPAG1AFC

I. Overview

GE DS200FGPAG1AFC is a fuel control module, specifically positioned as a "Precision Control and Safety Interlock Unit for Heavy-Duty Gas Turbine Fuel Flow". It focuses on addressing issues such as precise control of fuel supply, guarantee of combustion stability, and safety protection against over-temperature and over-pressure for gas turbines in scenarios like combined cycle power plants and industrial drives. It provides critical fuel control hardware support and safety barriers for the full-operating-condition operation of gas turbines, including start-up and speed-up, load adjustment, and shutdown cooling.

Deeply integrated into the Mark VIe control system architecture, this module adopts high-precision fuel flow closed-loop control technology, dedicated fuel valve drive circuits, and multiple safety interlock logics. It undertakes core tasks such as parsing fuel demand commands, collecting fuel flow signals, precisely adjusting fuel valve opening, monitoring combustion status, and executing emergency shutdown signals. This ensures the stability, accuracy, and safety of fuel control under harsh operating environments such as high load fluctuations, changes in fuel composition, and high temperature and pressure.

As a core execution unit of the Mark VIe fuel control system, the DS200FGPAG1AFC features core advantages including high-precision fuel flow control, adaptability to multiple types of fuel valves, millisecond-level safety response, and in-depth collaboration with the combustion system. Without the need for additional drive modules, it can directly connect to key gas turbine equipment such as fuel control valves, shut-off valves, and fuel nozzle actuators, realizing full-link closed-loop management of fuel control covering "demand-collection-adjustment-feedback".

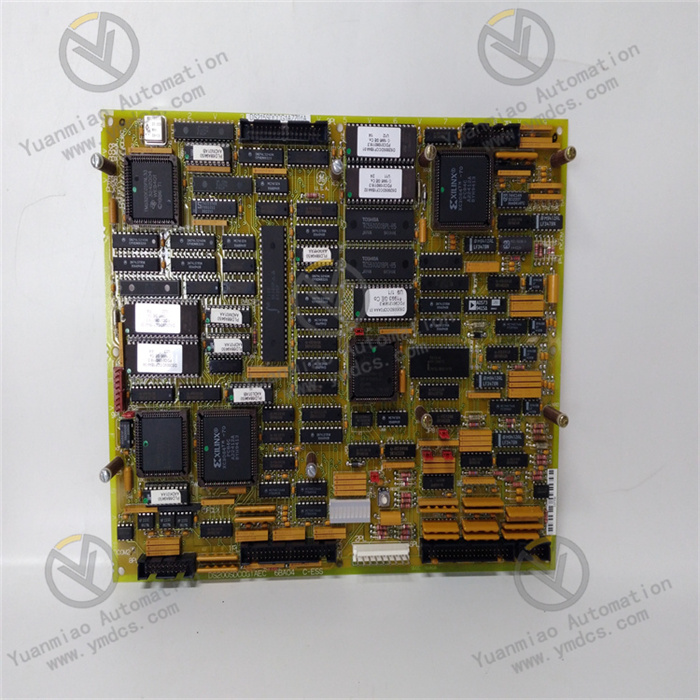

It is widely used in various heavy-duty gas turbine systems, such as GE 9F and 7F series gas turbines for combined cycle power plants, PG6500 series gas turbines for industrial drives, and fuel control scenarios of gas turbines for waste incineration power generation. The module possesses core characteristics including seamless collaboration with the Mark VIe system, precise and stable fuel valve drive, multiple combustion safety interlocks, wide-range fuel adaptability, and intelligent diagnosis. It can adapt to an operating environment of -20℃ to 65℃, meet strict electromagnetic compatibility requirements and long-term reliability standards under high-temperature environments, fully satisfying the rigorous demands of the gas turbine industry for fuel control accuracy, response speed, and safety redundancy.

II. Technical Parameters

III. Functional Features

1. Deep Integration with Mark VIe System, Seamless Collaboration for Fuel Control

Adopting the Mark VIe system’s dedicated Ethernet/IP real-time bus architecture, it achieves full-dimensional seamless integration with the main controller, ToolboxST configuration software, HMI operation interface, and combustion optimization system. The data interaction mechanism is optimized for the dynamic characteristics of gas turbine fuel control, ensuring collaborative consistency between fuel control, unit load adjustment, and combustion optimization.

The module can be directly embedded in the Mark VIe standard I/O rack, with mechanical fixation and electrical connection completed via a dedicated high-density bus connector—no additional adaptation modules or signal converters are required, and physical installation and system access can be completed in just 20 minutes. After accessing the system, the ToolboxST configuration software automatically identifies the module ID, interface configuration, and hardware version. Engineers can configure fuel control parameters (e.g., PID regulation coefficients, PWM drive parameters, protection thresholds, fuel type adaptation curves) via a graphical interface, supporting online debugging and offline simulation of fuel control logic without manual writing of underlying driver programs.

The data transmission between the module and the main controller adopts a real-time synchronous communication mechanism: the upload cycle of fuel status data is ≤2ms, and the delay of control command issuance is ≤1ms. This ensures rapid response and adjustment when the gas turbine load fluctuates suddenly. For example, when the unit load jumps from 50% to 100%, the module can complete the closed-loop process of "load demand-flow adjustment-valve position feedback" within 8ms, avoiding combustion fluctuations caused by delayed fuel supply.

2. Adaptability to Multiple Types of Fuel Valves, Precise and Reliable Drive

The PWM output channels are optimized for the drive characteristics of fuel valves, supporting continuously adjustable frequency of 100-1000Hz and duty cycle of 0-100%, with a driving current of 2A per channel, which can directly drive small and medium-sized proportional control valves. For large fuel valves, it supports expanding the driving capacity to 10A through an external power amplifier module, adapting to the drive requirements of the main fuel control valve of GE 9F series gas turbines.

The analog output channel has an accuracy of ±0.05% FS, which can output 4-20mA commands to drive fuel valves with positioners. Combined with 6 high-precision analog input channels to collect valve position feedback signals, a valve position closed-loop control is formed, with a valve position control accuracy of ±0.1% full stroke, ensuring the consistency between fuel flow and command requirements.

3. Fuel Flow Closed-Loop Control, Precise Adjustment Under Wide Operating Conditions

The cascade PID regulation architecture is divided into a "flow main loop" and a "valve position secondary loop". The main loop takes fuel flow demand as the target, performs PID calculation by collecting fuel flow sensor signals, and outputs the target valve position command. The secondary loop takes valve position feedback as the target, adjusts the fuel valve opening through PWM or analog output. The dual-loop collaborative control enables a flow regulation accuracy of ±0.5% rated flow, which is much higher than the industry average.

The module is equipped with a flow feedforward compensation function, which can predict fuel demand in advance according to the unit load change rate, and adjust fuel supply in advance when the load fluctuates suddenly, effectively suppressing flow fluctuations.

4. Multiple Safety Interlock Protections, Comprehensive Guarantee for Combustion Safety

The module has a built-in fuel over-flow protection logic: by comparing the real-time collected fuel flow signal with the preset threshold, if the flow exceeds 110% of the threshold, it outputs a flow limit signal within 2ms to control the fuel valve to reduce the opening; if the flow exceeds 120% of the threshold, it immediately triggers an emergency shutdown signal to close the main fuel valve and cut off the supply, with a response time of ≤1ms, avoiding combustion chamber over-temperature caused by over-flow.

The valve position jamming protection function compares the valve position command with the feedback signal. If the deviation exceeds 1% full stroke and lasts for 50ms, it is determined as a jamming fault, and it immediately switches to the redundant fuel valve and alarms to ensure uninterrupted fuel control.

5. Full Isolation Between Strong and Weak Electricity, Excellent Anti-Interference Capability

The isolation voltage between analog input channels is 1000V AC, and the isolation voltage between digital input and output channels is 1000V AC, avoiding signal crosstalk between different channels. For example, interference in the fuel pressure collection channel will not affect the accuracy of the valve position feedback collection.

The module housing is made of die-cast aluminum alloy with a high-temperature anti-corrosion coating. The internal circuit board adopts a grounded shielding design and high-temperature curing three-proof paint treatment, further enhancing anti-interference and anti-corrosion capabilities. It complies with the IEC 61000-4 series of electromagnetic compatibility standards and performs excellently in interference tests such as electrostatic discharge, electrical fast transient, and surge.

6. Full-Dimensional Intelligent Diagnosis, Significantly Improved Operation and Maintenance Efficiency

The module is equipped with 10 status indicator lights, including "Power Normal", "Operation Ready", "Communication Normal", "Drive Normal", "Over-Flow Alarm", "Abnormal Pressure Alarm", "Valve Position Jamming Alarm", "Flame Loss Alarm", "Redundancy Activated", and "Fault Shutdown". The on/off and blinking of the indicator lights enable quick judgment of fault types and scopes.