Description

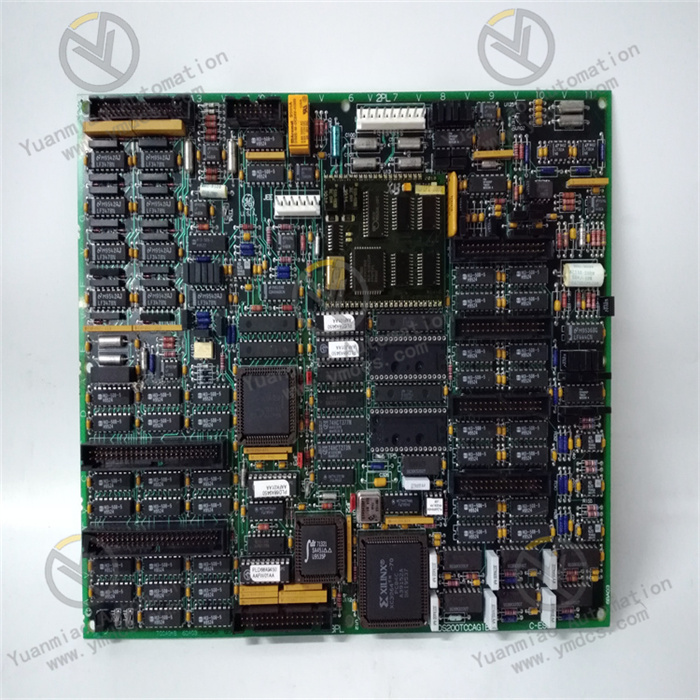

GE DS200NATOG1ABB

I. Overview

GE DS200NATOG1ABB is a speed control module positioned as the "Core Unit for Precise Speed Regulation and Overspeed Safety Protection of Large-Scale Steam Turbines". It is mainly applied in steam turbine control systems in fields such as thermal power generation, nuclear power generation, and industrial drives. Undertaking key tasks including stable speed control, precise acceleration rate adjustment, and overspeed fault protection, it provides reliable hardware support for the full operating cycle of steam turbines, ranging from start-up and speed-up, grid connection with load, normal operation to emergency shutdown.

Deeply integrated into the Mark VI control system architecture, this module adopts a high-precision speed closed-loop control algorithm, an independent overspeed protection logic unit, and a multi-redundancy design. It can directly connect to executive mechanisms of steam turbines such as high-pressure control valves, medium-pressure control valves, and main steam valves. Without the need for additional adapter modules, it realizes full-link closed-loop control covering "speed signal acquisition - command calculation - regulation output - status feedback". Its core advantages lie in high speed measurement accuracy, fast overspeed response (millisecond-level), wide adjustable range of acceleration rate, and strong compatibility with steam turbine regulation systems. It is applicable to various scenarios, including 300MW-1000MW thermal power steam turbines, nuclear power conventional island steam turbines, and large-scale backpressure steam turbines for industrial drives. Capable of long-term stable operation in harsh conditions such as a wide temperature range (-20℃ to 65℃), strong electromagnetic interference, and high vibration, it meets the strict requirements of the steam turbine industry for speed control accuracy (±0.1% rated speed) and safety redundancy.

II. Technical Parameters

III. Functional Features

1. In-depth Collaboration with Mark VI System, Seamless Connection of Control Links

The module adopts the dedicated VME bus architecture of the Mark VI system and can be directly embedded in a standard VME rack. Mechanical fixation and electrical connection are achieved through high-density bus connectors, with installation and access taking only 30 minutes. After access, the ToolboxST software can automatically identify module information. Engineers can configure speed control parameters (such as PID coefficients, acceleration rate curves, and overspeed thresholds) through a graphical interface, supporting online debugging and offline simulation without the need to write underlying drivers. The data transmission adopts a synchronous communication mechanism: the speed data upload cycle is ≤1ms, and the command issuance delay is ≤0.5ms. When the grid frequency fluctuates by ±0.5Hz, the regulation closed loop can be completed within 5ms, ensuring the speed is stabilized within ±0.1% of the rated value.

2. Adaptation to Multiple Types of Sensors, Accurate and Stable Speed Measurement

3. Precise Speed Control Under Full Operating Conditions, Flexible Adjustment of Acceleration Rate

4. Three-level Overspeed Redundant Protection, Excellent Safety Performance

5. Strong Anti-interference Design, Adaptation to Harsh Operating Conditions

6. Full-dimensional Intelligent Diagnosis, Improved Operation and Maintenance Efficiency

Equipped with 12 status indicator lights covering states such as power supply, communication, speed measurement, overspeed alarm, and sensor fault, it enables quick localization of fault scope. It supports module-level (power supply/communication fault), channel-level (sensor disconnection/output overcurrent), and function-level (PID logic/redundancy switching fault) diagnosis, with a fault response time of ≤2ms. Fault information (type, time, parameters) is uploaded to the main controller via the bus, triggering sound and light alarms and HMI pop-up prompts. 300 timestamped logs can be queried through ToolboxST. It supports online monitoring of data such as speed curves and control valve openings, and trend analysis can predict potential faults, reducing fault troubleshooting time by 90%.

IV. Common Faults and Solutions