Description

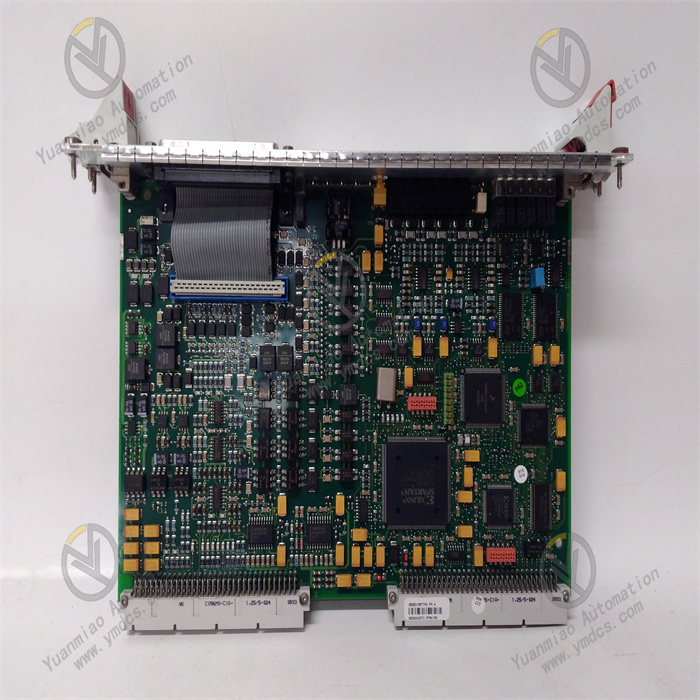

ABB AO895 3BSC690087R1

ABB AO895 3BSC690087R1 is an 8-channel intrinsically safe analog output module, positioned as a core signal conversion and execution control unit in industrial automation control systems. This module accurately converts digital signals from the controller into standard 4~20mA analog signals, and supports the HART communication protocol to enable bidirectional data transmission and remote device commissioning. Adopting group-level grounding isolation design and intrinsically safe protection scheme, it features excellent anti-interference capability and safety reliability.

With high-precision signal conversion circuits, comprehensive diagnostic protection mechanisms and wide environmental adaptability, the ABB AO895 3BSC690087R1 module can operate continuously and stably in complex industrial environments. It effectively improves system control accuracy and operation & maintenance efficiency, reduces the risk of equipment downtime caused by faults, and ensures the smoothness and safety of industrial production processes.

I. Product Features

1. Multi-channel Precise Output with Excellent Control Performance

2. HART Communication Support for Convenient Operation & Maintenance and Commissioning

3. Multiple Isolation and Protection for Safe and Reliable Operation

4. Comprehensive Diagnostic Mechanism for Timely Fault Early Warning

5. Wide Environmental Adaptability with Flexible Installation and Integration

II. Technical Parameters

1. Basic Parameters

- Model: ABB AO895 3BSC690087R1

- Product Type: 8-channel intrinsically safe analog output module

- Brand: ABB

- Core Functions: Convert digital signals to 4~20mA analog output, support HART communication and fault diagnosis

- Compatible Systems: ABB TU890, TU891, TU891Z series MTUs

- Key Code: AF

- Certification Standards: CE certification, EN 61010-1, EN 61010-2-201 electrical safety standards, ATEX/IECEx Zone 2 and other hazardous area certifications, RoHS & WEEE environmental protection certifications

- EMC Compliance: EN 61000-6-4, EN 61000-6-2

- Protection Grade: IP20

- Product Weight: 0.2kg (0.44lbs)

- Warranty Period: 12 months (subject to original factory standard warranty)

2. Electrical Parameters

- Output Channels: 8 channels, unipolar single-ended

- Signal Type: 4~20mA analog output

- Measurement Range: Under-range 2.5mA, Over-range 22.4mA

- Resolution: 12 bits

- Output Accuracy: Typical value 0.05%, Maximum value 0.1% (@650Ω load)

- Temperature Drift: Typical value 50ppm/℃, Maximum value 100ppm/℃

- Rise Time: 30ms (10%~90%)

- Output Load: < 725Ω at 20mA output, < 625Ω at 22mA output

- Protection Function: Short-circuit protection (current limiting)

- Power Supply Specifications: +5V module bus current consumption typical value 130mA; +24V external power supply current consumption typical value 250mA, maximum value < 330mA

- Power Loss: 4.25W

- Rated Insulation Voltage: 50V

- Dielectric Test Voltage: 500V AC

3. Mechanical and Environmental Parameters

- Dimensions (W×D×H): 45mm×102mm×119mm

- Operating Temperature: 0~+55℃ (32~131°F)

- Storage Temperature: -40~+70℃ (-40~158°F)

- Relative Humidity: 5%~95% (non-condensing)

- Intrinsically Safe Parameters: U0 (CENELEC/USA) is IIC; I0 (CENELEC/USA) is IIB; P0 (CENELEC/USA) is IIA

- Installation Method: Standard cabinet modular installation

III. Working Principle

The core working logic of the ABB AO895 3BSC690087R1 analog output module is "Power Supply - System Initialization - Signal Reception and Conversion - Analog Output and Communication - Status Monitoring and Diagnosis". The specific working process is as follows:

IV. Common Fault Troubleshooting

| Fault Phenomenon | Possible Causes | Troubleshooting and Solutions |

|---|---|---|

| No module response, R light off | Abnormal power supply of +5V module bus or +24V external power supply; loose or damaged power connection cables; communication timeout between module and controller; incorrect module installation position | Use a multimeter to measure the voltage of +5V module bus and +24V external power supply to confirm that the voltage is within the normal range. Check whether the power connection cables are loose or damaged, re-plug and tighten the connections. If the power supply is normal, check the communication link between the module and the controller to troubleshoot bus connection problems. Verify that the module installation position complies with the system configuration requirements and confirm there is no misalignment. If there is still no response, internal module failure may be the cause, and the module needs to be replaced. |

| Output signal over-range, W light on | Digital commands issued by the controller exceed the module output range; incorrect configuration of module output range; abnormal load of on-site executive devices | Read the digital commands issued by the controller or HART communicator to confirm that the commands are within the normal control range. Check the module output range configuration parameters, and re-calibrate the configuration if there is an error. Test the load resistance of on-site executive devices to confirm that the load is within the module adaptation range (< 725Ω at 20mA). If the load is abnormal, the executive device needs to be repaired or replaced. |

| HART communication failure, TX light off | Mismatched HART communication protocol configuration; poor contact or damaged communication lines; module communication function failure | Verify the HART communication protocol configuration between the module and the controller to ensure parameter consistency. Check whether the HART communication line connections are firm, troubleshoot line damage, and replace the communication line if necessary. If the configuration and lines are normal, module communication function failure may be the cause, and it is necessary to contact ABB authorized after-sales service for maintenance or replacement. |

| Large output signal deviation, low control accuracy | Uncalibrated module output accuracy; excessive on-site electromagnetic interference; load resistance exceeding the adaptation range; impact of temperature drift | Re-calibrate the module output accuracy via HART communicator. Check whether the module installation position is close to strong interference sources, and install a metal shield or adjust the installation position if necessary. Confirm that the load resistance of on-site executive devices meets the requirements. In extreme temperature environments, check whether the ambient temperature exceeds the module operating range, and install a temperature control device if necessary. |

| Fault light (F light) always on, indicating line fault | Broken output line; external voltage short circuit; poor line contact | Disconnect the module power supply, check the on-off status of the output line to troubleshoot broken lines or poor contact. Test whether there is an external voltage short circuit in the output line; if a short circuit exists, troubleshoot the on-site circuit to eliminate the short circuit hazard. Re-power the module after repairing the line fault and observe whether the fault light returns to normal. |

| Module reports "invalid slot" error | Incorrect module installation slot; mismatch between system configuration and hardware | Verify the system configuration file to confirm that the module installation slot complies with the configuration requirements. If the slot is incorrect, re-adjust the installation position. If the slot is correct but the error persists, check the compatibility between the system hardware configuration and the module model to ensure there is no configuration conflict. |