Description

GE DS200EXPSG1ACB

GE DS200EXPSG1ACB is a core power supply module developed for the Mark VIe Distributed Control System (DCS). It belongs to the EX2100 series I/O module family and is mainly positioned as the "power supply guarantee hub" for the control systems of large rotating machinery such as industrial steam turbines, gas turbines, and generators. Relying on GE's profound technical accumulation in the field of industrial control, this module adopts a highly reliable power conversion circuit, multiple redundancy design, and enhanced anti-interference architecture. It undertakes the key task of providing stable and accurate DC power for core components of the Mark VIe system, such as I/O modules, processor modules, and communication modules, while also featuring core functions including power status monitoring, fault alarm, and redundancy switching.

As a dedicated power module for the Mark VIe control system, DS200EXPSG1ACB is highly compatible with the system's hardware architecture and software platform. It can be directly connected to the system's standard I/O rack and realize real-time communication with the system controller through the backplane bus. Parameter configuration and status feedback can be completed without additional adaptive equipment. It is widely used in key industrial fields such as electric power, petrochemicals, metallurgy, and shipping, providing uninterrupted power support for core processes of large rotating machinery, such as start-stop control, operation monitoring, and fault protection. It is a key core component that ensures the stable operation of the control system and prevents equipment shutdown or safety accidents caused by power supply abnormalities. The module has a wide voltage input range, high output accuracy, strong anti-interference capability, and convenient operation and maintenance characteristics. It can adapt to complex power grid fluctuations and electromagnetic interference environments in industrial sites, significantly improving the power supply reliability and operational stability of the control system.

The module adopts a wide-range AC input design, supporting 100V AC ~ 240V AC input voltage and 50Hz/60Hz frequency auto-adaptation. It can adapt to power grid standards of different countries and regions, while also resisting common power grid voltage fluctuations (such as ±20% fluctuation) in industrial sites. The output end provides dual-channel output of 5V DC (high precision) and 24V DC. Among them, the 5V DC output has a voltage accuracy of ±0.05V and a voltage regulation rate of ≤0.1%, which can provide stable power supply for core precision components of the Mark VIe system, such as processors and memories; the 24V DC output can meet the power supply needs of peripheral devices such as I/O modules and sensors. Through the built-in high-precision voltage feedback regulation circuit, the module can real-time compensate for voltage deviations caused by load changes and input fluctuations, ensuring output voltage stability. For example, when the load of the 5V output channel changes abruptly from 5A to 20A, the voltage fluctuation range is ≤0.01V, which is far better than the industry average, ensuring the stable operation of core components of the control system.

In response to the strict requirements for power supply continuity in key industrial fields such as electric power and petrochemicals, the module supports 1+1 hot redundancy configuration. When two modules operate in parallel, automatic load current sharing can be achieved (current sharing error ≤5%), avoiding overload of a single module. When the main module fails (such as output overcurrent, overvoltage, module overheating, etc.), the built-in redundancy switching circuit can complete the main-standby switching within ≤1ms, and the output voltage fluctuation during switching is ≤0.1%, ensuring uninterrupted power supply for the load and completely preventing control system shutdown caused by power module failure. In the redundant system, the operating status (such as output current, temperature, fault status) of the two modules can be uploaded to the Mark VIe controller in real-time through the backplane bus. Operators can intuitively monitor the operating status of the redundant system through the HMI (Human-Machine Interface). For example, when the output current of one of the modules is abnormal, the system will automatically issue an early warning and display the fault module number, facilitating accurate handling by maintenance personnel.

The module has built-in full-link protection mechanisms for input and output, forming an all-round safety protection network. The input side is equipped with 10A fuse protection, overvoltage protection (260V AC threshold), and undervoltage protection (85V AC threshold), which can effectively resist overvoltage shocks, undervoltage abnormalities, and short-circuit faults on the input side; the output side is equipped with overcurrent protection (thresholds 22A and 5.5A respectively), overvoltage protection (thresholds 5.5V and 26V respectively), and short-circuit self-recovering protection for the 5V and 24V channels. When the load has a short circuit or overcurrent, the module will immediately cut off the output of the corresponding channel and trigger an alarm. After the fault is eliminated, the power supply will be automatically restored, preventing the fault from spreading to the load equipment or other system components. In addition, the module has a built-in temperature protection function: when the internal temperature exceeds 75℃, it will automatically reduce the output power and issue an overheating early warning; when the temperature exceeds 85℃, it will force a shutdown to prevent the module from burning and extend the service life of the equipment.

The module has comprehensive status monitoring and diagnosis functions. Through built-in voltage, current, and temperature sensors, it can real-time collect key parameters such as input voltage, 5V/24V output voltage, output current, and internal module temperature, and upload the data to the Mark VIe controller through the backplane bus. Operators can intuitively view the real-time values and change curves of various parameters through the system HMI (for example, real-time monitoring of the load current change of the 5V output channel to predict load abnormalities in advance). The front of the module is equipped with LED status indicators (power indicator, operation indicator, fault indicator, redundancy status indicator). The operating status of the module can be quickly judged through the color and blinking mode of the indicators (e.g., steady green indicates normal operation, blinking red indicates output overcurrent fault), allowing maintenance personnel to initially locate problems without disassembling the module. At the same time, the module supports fault code upload function, where different fault types correspond to unique fault codes (e.g., E01 indicates input overvoltage, E02 indicates 5V output overcurrent), facilitating quick and accurate diagnosis of fault causes.

The module adopts a dual electrical isolation design between input and output, and between output and ground. The isolation level reaches 3kVrms (between input and output), which can effectively block ground loop interference and high-voltage intrusion in industrial sites, ensuring the safety of the internal circuit of the module and load equipment. It has passed the full-item anti-interference certification of IEC 61000-4, with ESD protection capability of ±8kV contact discharge and ±15kV air discharge, which can resist electrostatic interference caused by friction between operators and equipment; it also has ±2kV surge and burst immunity, which can withstand pulse interference caused by power grid lightning strikes and motor start-stop. In the steam turbine control system of the electric power industry, the module can operate stably in a strong electromagnetic environment with dense high-voltage equipment and high-power motors, without being affected by electromagnetic interference, ensuring continuous and stable power supply for the control system and avoiding power supply abnormalities or module misoperations caused by interference.

The module adopts a 35mm DIN rail snap-on installation design. Installation and disassembly only require manual operation of the snap, no special tools are needed, and a single person can complete the module installation and fixation; the front end is equipped with pluggable terminals. After wiring is completed, the entire terminal can be plugged and unplugged, and no repeated wiring is required during subsequent maintenance, greatly improving the operation and maintenance efficiency. The module supports hot-swapping function. Under redundant configuration, the faulty module can be replaced without shutting down the system. After replacement, the system automatically identifies the new module and incorporates it into the redundant system. The entire process takes ≤5 minutes, avoiding production line shutdown caused by module replacement. In addition, the module uses long-life components (such as military-grade capacitors and high-efficiency cooling fans), with a design life of 100,000 hours and an average annual failure rate of ≤0.01 times, significantly reducing later operation and maintenance costs and shutdown losses.

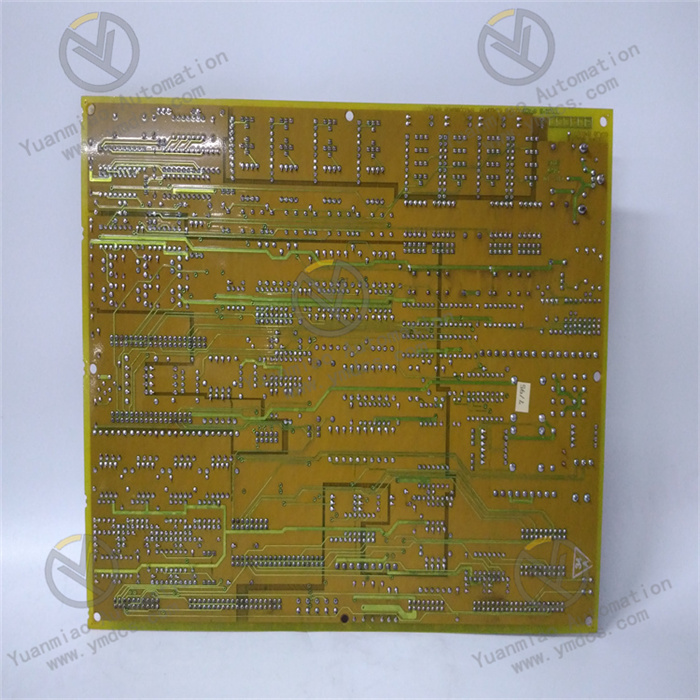

![]()