Description

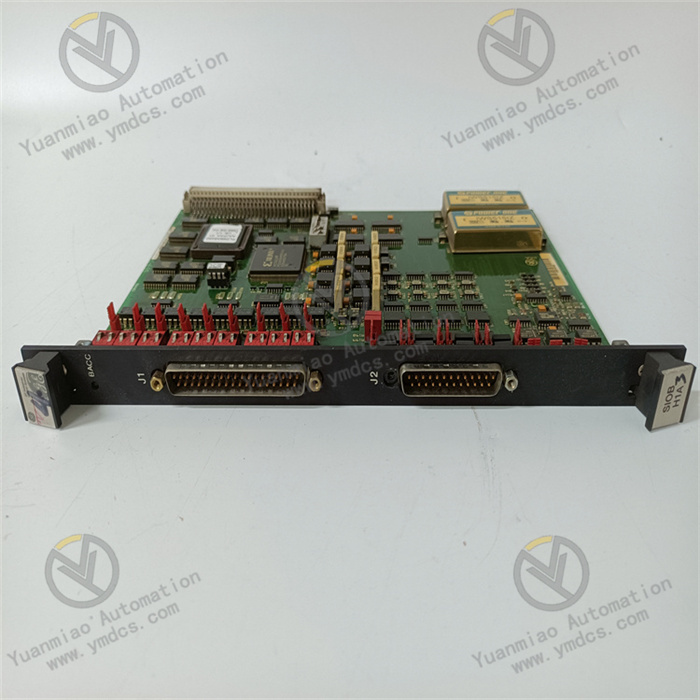

GE IS200ACLEH1AAA

GE IS200ACLEH1AAA is a core analog input/output (I/O) module belonging to the IS200 series I/O module family. It is primarily positioned as the "signal acquisition and control execution hub" for industrial steam turbines, gas turbines, generators, and large-scale industrial production lines. Leveraging GE's decades of technical accumulation in the industrial control field, this module adopts a highly reliable signal conditioning circuit, a multi-channel independent isolation architecture, and an enhanced anti-interference design. It undertakes key tasks such as real-time acquisition and filtering of analog signals (e.g., signals from pressure, flow, liquid level, and temperature sensors) in industrial sites, as well as the precise output of control commands. Meanwhile, it is equipped with functions including channel fault diagnosis, signal abnormality alarm, and high-speed communication with the system controller.

As a key I/O interface module for the Mark VIe control system, IS200ACLEH1AAA is highly compatible with the system's hardware architecture and software platform. It can be directly integrated into the system's standard I/O rack and achieve microsecond-level data interaction with the controller via the backplane bus. Without the need for additional signal converters or adaptation software, it enables rapid configuration of parameters such as channel type, measurement range, and alarm threshold. It is widely used in key industrial fields such as electric power, petrochemicals, metallurgy, and rail transit, providing stable signal transmission and execution support for core processes of large-scale equipment, including operating status monitoring, closed-loop control of process parameters, and emergency fault protection. It is a critical core component that ensures efficient collaboration between the control system and on-site equipment, and prevents production accidents caused by signal distortion or transmission delay. The module features multi-type signal adaptation, high-precision acquisition and output, strong anti-interference capability, and convenient operation and maintenance. It can adapt to complex industrial site environments such as high temperature, high vibration, and strong electromagnetic interference, significantly improving the overall reliability and control accuracy of the control system.

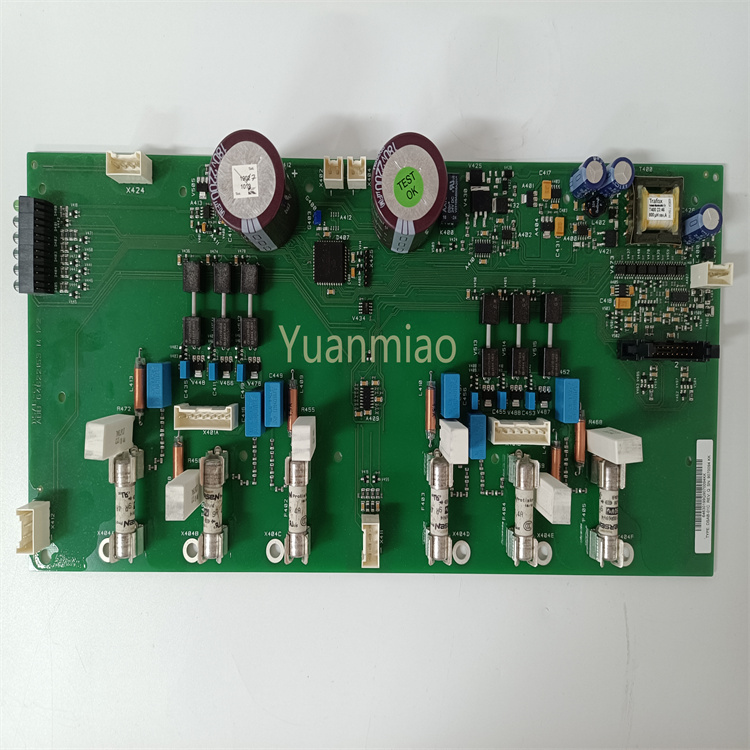

The module adopts a highly flexible I/O channel design. The 8 input channels can be independently configured via software into multiple signal types such as 4-20mA current, 0-5V/0-10V voltage, thermocouple, and platinum resistor. The 4 output channels can be independently configured as 4-20mA current or 0-5V/0-10V voltage output. It can adapt to different sensors and actuators without hardware replacement, significantly improving the flexibility of system integration. According to the characteristics of different signals, the module is equipped with dedicated conditioning circuits: the current/voltage channels use high-precision signal amplification chips to ensure accurate acquisition of weak signals; the thermocouple channels have a built-in high-precision cold-junction compensation module with a compensation accuracy of ±0.1℃; the platinum resistor channels support 3-wire/4-wire connection to effectively eliminate wire resistance errors. In petrochemical production equipment, input channels can be used to collect signals from pressure sensors (4-20mA) and temperature sensors (PT100) respectively, and output channels can drive control valves (4-20mA), enabling the same module to centrally collect and control multiple parameters.

The input channels of the module adopt 16-bit high-precision ADC (Analog-to-Digital Converter) chips, combined with low-noise signal amplification and filtering circuits, to achieve accurate acquisition of analog signals. Among them, the acquisition accuracy of current/voltage signals reaches ±0.05% FS, and the accuracy of platinum resistors within the core range of -50℃-200℃ reaches ±0.1℃, which is far superior to similar products in the industry. The output channels use 16-bit high-precision DAC (Digital-to-Analog Converter) chips, combined with high-precision reference voltage sources and closed-loop calibration circuits, with an output accuracy of ±0.05% FS (current output). The output signal has strong stability, with a voltage fluctuation of ≤0.01V within the full load range. The module supports a single-channel sampling rate of 1000Hz and a simultaneous sampling rate of ≥500Hz for 8 channels, which can accurately capture high-speed dynamic signals (e.g., steam turbine vibration signals). In the control system of a precision chemical reactor, the error of the reaction pressure signal collected by the module is ≤0.02MPa, and the output control signal drives the control valve to operate, controlling the reaction pressure fluctuation within ±0.05MPa to ensure the stability of the reaction process.

It adopts a triple electrical isolation design between "input channels and backplane bus", "between channels", and "between input and output", with an isolation level of 2.5kVrms (between input and bus). This can effectively block ground loop interference, high-voltage intrusion, and signal crosstalk between channels in industrial sites, ensuring the safety of the module and the controller. It has passed the full-item anti-interference certification of IEC 61000-4, with ESD protection capability of ±8kV contact discharge and ±15kV air discharge, as well as ±2kV surge and burst immunity, which can resist strong electromagnetic interference caused by power grid lightning strikes and high-power motor start-stop. The module adopts an enhanced PCB layout and shielding design to further improve anti-interference performance. In the hot rolling production line of a steel plant, the module can work stably in harsh environments with high temperature, high dust, and strong electromagnetic interference, accurately collecting roll temperature and rolling force signals, with no distortion in output signals, avoiding control misoperations caused by interference.

The module is equipped with a comprehensive full-channel fault diagnosis function, which can real-time monitor the sensor connection status (open circuit, short circuit) and signal amplitude abnormality (over-range, under-range) of input channels, as well as the load abnormality (overload, short circuit) of output channels and internal circuit faults (power abnormality, chip fault) of the module. When a fault occurs, the module immediately triggers an alarm, uploads the fault information (fault channel number, fault type, fault time) to the Mark VIe controller via the backplane bus, and displays the fault code on the system HMI interface (e.g., E01 indicates open circuit of input channel 1, E10 indicates short circuit of output channel 1). The front of the module is equipped with 16 LED status indicators (8 inputs + 4 outputs + power + communication + alarm). The operating status can be intuitively judged through the indicator color (green - normal, red - fault, yellow - alarm). Maintenance personnel can quickly locate the fault point without disassembling the module, reducing the fault troubleshooting time from the traditional 2 hours to less than 10 minutes.

The module realizes high-speed communication with the controller via the Mark VIe backplane bus, with a communication rate of 1Gbps and a data transmission delay of ≤10μs, ensuring real-time upload of collected signals and rapid issuance of control commands to meet the needs of high-speed closed-loop control. The module is deeply adapted to the Mark VIe system software. After being connected to the system, the RobotWare operating system can automatically identify information such as the module model and channel configuration. No manual driver installation is required, and visual configuration of parameters such as signal type, measurement range, and alarm threshold can be completed through the system's "channel mapping" function. It supports online parameter modification and download, and the modifications take effect without restarting the module, improving debugging efficiency. In the steam turbine control system, the module can real-time upload key signals such as bearing temperature and speed, and quickly receive adjustment commands from the controller to achieve precise closed-loop control of the steam turbine speed, with a response delay of ≤5ms.

It adopts a 35mm DIN rail snap-on installation design. Installation and disassembly only require manual operation of the snap, no special tools are needed, and a single person can fix the module. The front end is equipped with pluggable terminals. After wiring is completed, the entire terminal can be plugged and unplugged, and no repeated wiring is required during subsequent maintenance, greatly improving the efficiency of installation and operation & maintenance. The module supports the hot-swapping function, which allows replacement of faulty modules without shutting down the system. After replacement, the system automatically identifies the new module and restores parameter configuration. The entire process takes ≤5 minutes, avoiding production line shutdown losses caused by module maintenance. The module uses long-life components (e.g., military-grade capacitors, high-efficiency heat sinks), with a design life of 100,000 hours and an average annual failure rate of ≤0.01 times, significantly reducing later operation & maintenance costs.

![]()