Description

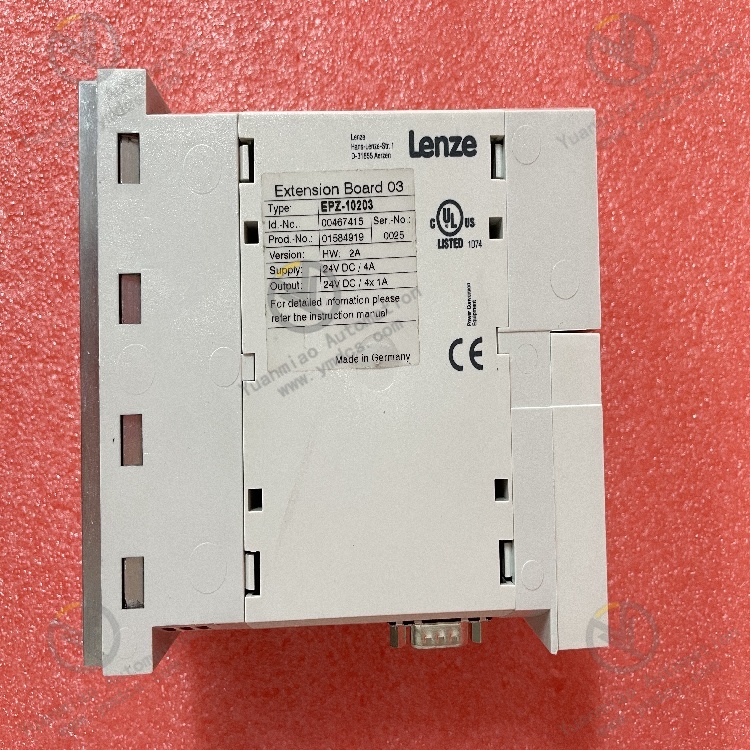

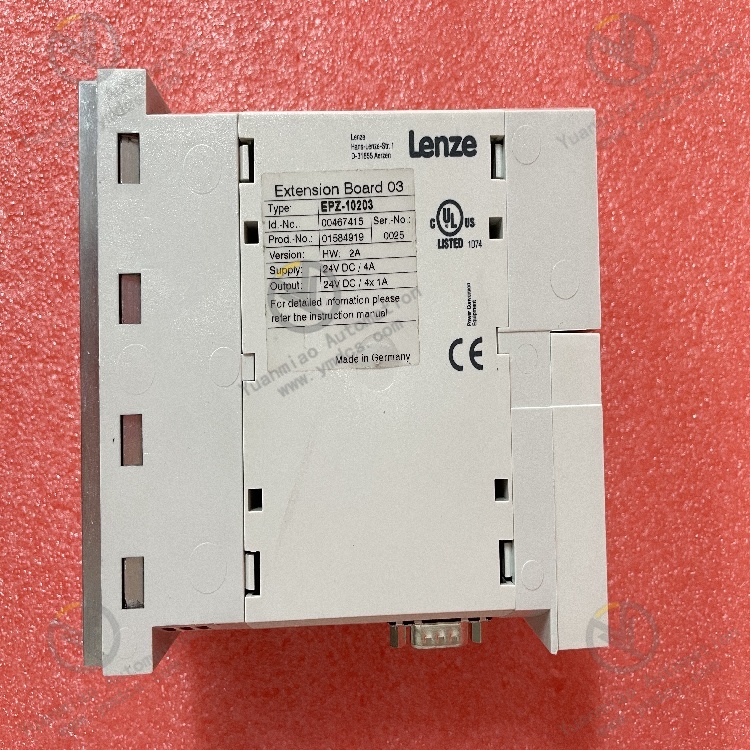

LENZE EPL-10200-XX Ac Drive Module

The LENZE EPL-10200-XX is a high-performance programmable logic controller (PLC) or AC drive module used in industrial automation systems.

- Equipped with advanced vector control technology, it enables precise speed regulation and torque control, providing high-precision and reliable control for industrial applications.

- Supports multiple communication interfaces such as RS-485, CANopen, and EtherCAT, allowing seamless integration with other industrial devices and systems to facilitate the construction of complex automation control systems.

- Features a wide voltage and frequency range, adapting to different power supply requirements and operating conditions. It has strong environmental adaptability and can operate stably within a temperature range of -15°C to +50°C.

- Rated power output: Up to 10kW

- Voltage range: Three-phase 380V to 480V

- Frequency range: 0.5Hz to 650Hz

- Protection level: IP20

- Communication interfaces: RS-485, CANopen, EtherCAT, etc.

- Dimensions: 224mm×132mm×180mm

Suitable for various industrial automation scenarios, including:

- Control of production lines in manufacturing

- Process control in the food and beverage industry

- Automation line control in the automotive industry

It enables precise control of motors, drives, and other motion control components to improve production efficiency and product quality.

- Connect to the controller via programming software or a handheld programmer, and set various parameters according to actual application needs, such as input/output port definitions, control logic programming, and communication parameter configuration.

- Download the compiled control program into the controller's memory through programming equipment, allowing the controller to operate according to the preset program logic.

- During equipment operation, real-time monitoring of the controller's operating status can be achieved via programming software or a host computer monitoring system, including the status of input/output signals, register values, and program execution flow, to promptly identify and adjust issues.

- Regularly check for loose hardware connections of the controller, clean dust from the device surface, and timely update and optimize control programs according to changes in production processes.

- Check whether the power input is normal, including whether the voltage is within the specified range and whether there are open or short circuits in the power supply lines. If the power module is damaged, replace it with a module of the same model.

- Confirm that the communication interface connections are correct and check whether communication parameter settings (e.g., baud rate, data bits, parity bits) match those of other devices. If there are issues with communication lines, repair or replace them; if the interface is damaged, repair or replace the communication interface module.

- Check the indicator light status of the input/output modules to determine whether signals are being received or transmitted. If input signals are normal but the controller does not respond, the issue may be a faulty input module or program logic errors. If the controller outputs signals but external devices do not act, check the output module, output lines, and external devices for normality.

- Check for syntax errors, logical errors, or infinite loops in the program. Use debugging tools to step through the program execution process, identify the problem, and make modifications.

![]()