Description

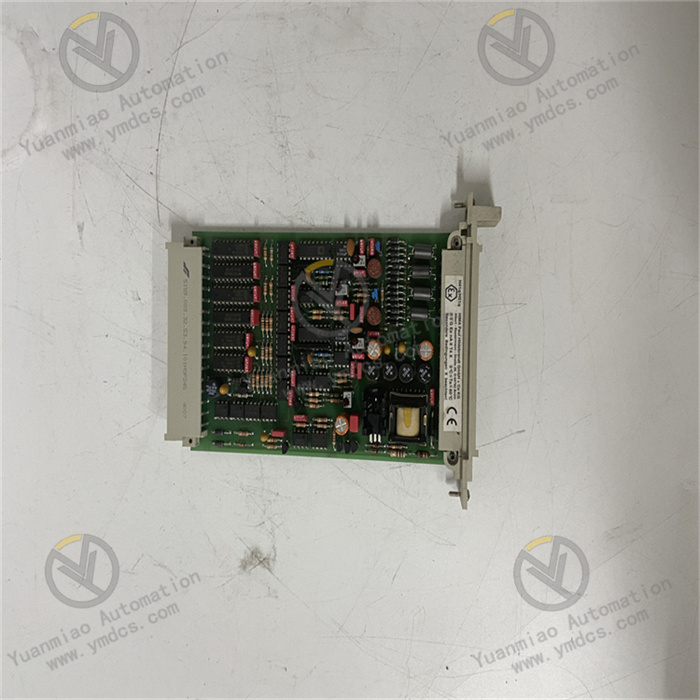

GE IS210WSVOH1AE

I. Overview

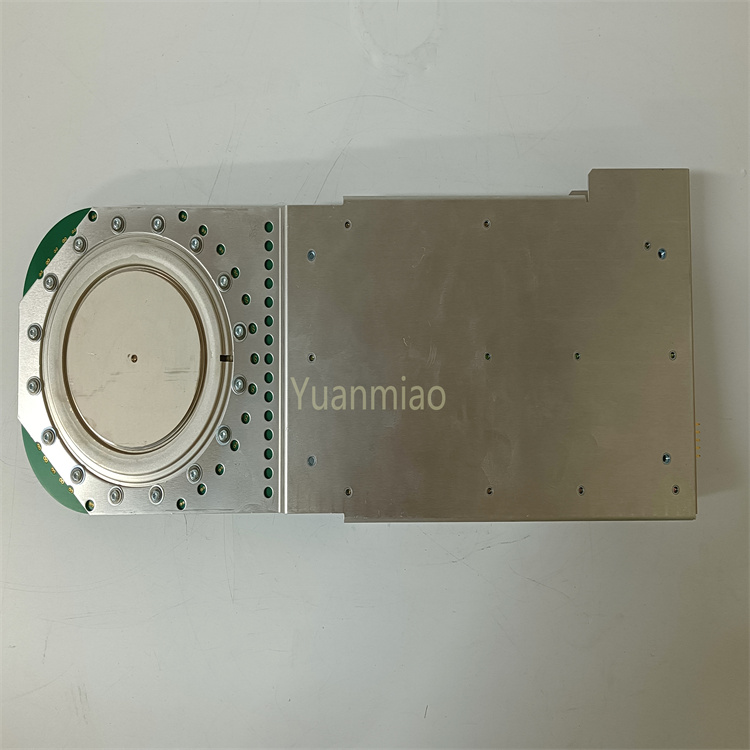

The GE IS210WSVOH1AE is a high-density analog output module for distributed control systems. Its core value lies in providing a solution for industrial process control that enables "accurate digital-to-analog conversion, independent multi-channel driving, and highly reliable signal transmission". Serving as the "command executor" connecting controllers and on-site actuators, it converts the digital control commands from the Mark VIe controller into standard 4-20mA/0-10V DC analog signals through "parallel multi-channel output, isolation protection, and linear compensation". These signals drive actuators such as control valves, frequency converters, and proportional valves, making it suitable for scenarios including power boiler water level regulation, oil and gas pipeline pressure control, and metallurgical rolling mill hydraulic adjustment. It is a key I/O component ensuring the stability of process parameters.

This module adopts a compact modular design and supports rack-level redundancy configuration for the Mark VIe system. When used with ControlST programming software, it enables output parameter calibration and fault diagnosis. It is widely applied in global industrial process control fields, especially suitable for analog control loops requiring high linearity and long-term stability.

II. Technical Specifications

(I) Core Signal Conversion and Output Parameters

1. Output Channel Configuration

- Number of Channels: 8 independent analog output channels, each supporting software-configurable signal types:

- Current Output: 4-20mA DC, load impedance 10Ω-500Ω (at full-scale output), short-circuit protection current ≤25mA (self-recovering);

- Voltage Output: 0-10V DC, load impedance ≥1kΩ, overvoltage protection threshold 15V DC (clamping protection);

- Output Accuracy:

- Current Output: ±0.05% FS (at 25℃ ambient temperature), ±0.1% FS (within 0℃-60℃ operating temperature range);

- Voltage Output: ±0.1% FS (at 25℃ ambient temperature), ±0.2% FS (within 0℃-60℃ operating temperature range);

- Resolution: 16-bit DAC (Digital-to-Analog Converter), minimum output step: 0.3125μA for current output (4-20mA range), 0.195mV for voltage output (0-10V range).

2. Signal Conversion and Dynamic Characteristics

- Conversion Response Time: From digital command update to stable analog output (within ±0.1% FS error) ≤10ms, meeting the needs of fast adjustment scenarios (e.g., boiler water level control);

- Linearity: ≤±0.02% FS (within full-scale range), no inflection point nonlinear deviation, ensuring complete synchronization between actuator action and command;

- Temperature Drift Characteristics: ±5ppm/℃ (current output), ±10ppm/℃ (voltage output). Within the temperature fluctuation range of -10℃-60℃, the output deviation is negligible, eliminating the need for frequent calibration.

(II) Electrical and Environmental Parameters

1. Power Supply and Power Consumption

- Power Supply Method: Powered via the backplane of the Mark VIe standard I/O rack (24V DC redundant power supply, provided by KJ2001 series power modules). The rated power consumption of a single module is ≤8W (when 8 channels are at full-load output);

- Power Supply Protection: Equipped with reverse polarity protection (no damage when input voltage is reversed), overcurrent protection (automatic current limiting when total overcurrent ≤1A), and undervoltage protection (output maintains "last value" state when power supply voltage <18V DC);

- Isolation Performance:

- Inter-channel Isolation: 2500V AC (withstand voltage for 1 minute), preventing signal crosstalk between channels;

- Channel-to-Backplane Isolation: 1500V AC (withstand voltage for 1 minute), common-mode interference resistance of ±250V DC, complying with the IEC 61131-2 industrial isolation standard.

2. Environmental Adaptability

- Operating Environment: Temperature 0℃-60℃ (no derating), storage temperature -40℃-85℃, relative humidity 5%-95% RH (no condensation);

- Protection Class: The module itself has an IP20 protection class (must be installed in a Mark VIe standard control cabinet). The PCB board is treated with a moisture-proof coating, adapting to dusty and high-humidity environments in industrial workshops;

- Electromagnetic Compatibility: Passed IEC 61000-4-2 (±8kV contact discharge), IEC 61000-4-4 (±2kV electrical fast transient), and IEC 61000-4-6 (10V/m radio frequency radiation) tests, resisting electromagnetic interference generated by frequency converters and high-power motors.

(III) Communication and System Compatibility Parameters

1. Communication Interfaces and Redundancy

- Backplane Communication: Communicates with the main controller (e.g., IS200TBSCH1A) via the dedicated high-speed backplane bus of the Mark VIe I/O rack (100Mbps). The data update cycle is ≤5ms, supporting deterministic control command transmission;

- Redundancy Support: Supports rack-level redundancy (configuring 2 identical I/O racks with automatic main-standby switching). When a module fails, the module in the standby rack seamlessly takes over the output, with a switching time ≤1ms, ensuring no interruption of control signals;

- Diagnostic Communication: Built-in intelligent diagnostic chip, which can report channel faults (e.g., short circuit, overload), power supply status, DAC abnormalities, and other information via the backplane bus, supporting remote parameter calibration and fault reset.

2. System Adaptability

- Software Support: Compatible with GE ControlST V9.0 and above programming software, supporting graphical configuration of channel signal types, output ranges, and fail-safe values (e.g., 4mA or 20mA output when power is off);

- Device Compatibility: Directly compatible with actuators such as GE Rosemount 3051 transmitters and Fisher DVC6200 intelligent valve positioners, and compatible with third-party 4-20mA/0-10V devices (e.g., Siemens S7-1200 PLC analog input modules).

III. Functional Features

(I) High-Density and High-Precision Output, Simplifying Control Architecture

The 8 independent channels and high precision of ±0.05% FS enable simultaneous driving of multiple actuators, reducing the number of modules and cabinet space. For example, in boiler control of a thermal power plant, one IS210WSVOH1AE module can output simultaneously:

- 4-20mA signals to drive the feedwater control valve (controlling boiler water level), desuperheating control valve (controlling steam temperature), air supply control valve (controlling furnace negative pressure), and induced draft control valve (controlling flue gas emission);

Compared with traditional 4-channel analog output modules, it reduces installation space and wiring workload by 50%. Meanwhile, the 16-bit DAC ensures independent and interference-free output of each channel, with water level control accuracy of ±5mm and steam temperature control accuracy of ±2℃.

(II) Full Isolation and Anti-Interference Design, Ensuring Signal Reliability

The dual isolation between channels and between channels and the backplane, combined with a wide range of electromagnetic compatibility tests, can effectively resist ground loops and electromagnetic noise in industrial sites. In the pressure control of petrochemical pipelines, the module outputs 4-20mA signals to drive pressure control valves. Even if strong electromagnetic interference is generated by the start-stop of on-site frequency converters, the output signal fluctuation is still ≤±0.02% FS, avoiding pressure overshoot caused by incorrect valve actions. The short-circuit protection function can prevent module damage caused by broken actuator cables, and the output automatically recovers after the fault is eliminated, without manual reset.

(III) Flexible Configuration and Fail-Safe, Adapting to Diverse Scenarios

- Signal Type Switching: Any channel can be configured as current or voltage output via software. It can adapt to different actuators (e.g., 4-20mA control valves and 0-10V frequency converters) without replacing hardware, reducing spare parts inventory;

- Fail-Safe Value Setting: Supports customizing the output value when a channel fault occurs (e.g., power failure, communication interruption) (e.g., 4mA for valve closing, 12mA for maintaining opening). In the control of power plant steam pipelines, 4mA is output when power is off to close the control valve, avoiding the risk of steam leakage;

- Remote Calibration: Zero-point and full-scale calibration of each channel can be performed remotely via ControlST software, without on-site module disassembly. The calibration error is ≤±0.01% FS, reducing downtime for maintenance.

(IV) Redundancy and Diagnostics, Reducing Operation and Maintenance Costs

The rack-level redundancy configuration ensures no interruption of critical control loops. In the gas purification system of a metallurgical blast furnace, the IS210WSVOH1AE modules in the main and standby racks simultaneously output signals to drive the gas shut-off valve. When the main module fails, the standby module takes over within 1ms, avoiding gas leakage. The built-in diagnostic function can monitor channel status in real time. When the output current of a channel is continuously ≥25mA (short circuit), it immediately reports a "channel short-circuit fault" and cuts off the output of that channel to protect the module and actuator. Maintenance personnel can quickly locate cable problems through fault codes, improving maintenance efficiency by 60%.

IV. Application Fields

(I) Power Industry: Auxiliary Control of Boilers and Steam Turbines

- Boiler Water Level Regulation: The module outputs 4-20mA signals to drive the feedwater control valve, realizing closed-loop control based on the feedback from the boiler water level transmitter (4-20mA). The water level control accuracy is ±5mm, avoiding steam entrainment due to excessively high water levels or dry boiling due to excessively low water levels;

- Steam Turbine Lubricating Oil Pressure Control: Outputs 0-10V signals to control the speed of the lubricating oil pump frequency converter, stabilizing the oil pressure at 0.25MPa±0.02MPa to ensure the lubrication of steam turbine bearings. The module's temperature drift characteristic ensures no significant oil pressure fluctuation when the oil temperature changes.

(II) Petrochemical Industry: Control of Pipelines and Reactors

- Crude Oil Pipeline Pressure Control: The module outputs 4-20mA signals to drive pipeline pressure control valves, realizing stable pressure control (0.8MPa±0.03MPa) based on the feedback from pressure transmitters, avoiding pipeline rupture due to excessively high pressure or transportation interruption due to excessively low pressure;

- Reactor Temperature Control: Outputs 4-20mA signals to drive the jacket cooling water control valve, realizing reaction temperature control (80℃±1℃) in conjunction with a temperature transmitter (4-20mA). The linearity of ≤±0.02% FS ensures smooth valve action without temperature overshoot.

(III) Metallurgical Industry: Control of Rolling Mills and Blast Furnaces

- Rolling Mill Hydraulic Roll Gap Control: The module outputs 4-20mA signals to drive hydraulic servo valves, controlling the roll gap of the rolling mill's work rolls. The roll gap control accuracy is ±0.01mm, meeting the needs of thin strip steel rolling. The 16-bit resolution ensures accurate execution of small roll gap adjustments;

- Air-Fuel Ratio Control of Blast Furnace Hot Blast Stoves: Outputs 4-20mA signals to drive gas control valves and combustion air control valves respectively, realizing accurate control of the air-fuel ratio at 1:10±0.1, ensuring full fuel combustion and stabilizing the hot blast temperature at 1200℃±10℃.

(IV) Municipal and Light Industry: Water Treatment and Production Line Control

- Aeration Control in Sewage Treatment: The module outputs 4-20mA signals to drive aeration valves, adjusting the aeration volume based on the feedback from a dissolved oxygen transmitter (0-20mg/L). The dissolved oxygen control accuracy is ±0.5mg/L, reducing aeration energy consumption;

- Flow Control in Food Processing Lines: Outputs 0-10V signals to control the speed of the material transfer pump frequency converter, stabilizing the flow at 50L/min±1L/min to ensure the consistency of processing technology. The fail-safe value is set to 0V (pump stop) to avoid material overflow.

V. Selection and Engineering Implementation Recommendations

(I) Selection Criteria

- Channel Quantity Matching: This module is preferred when the single system requires 8 or fewer analog output channels; for more than 8 channels, multiple modules can be cascaded, or the 16-channel version IS210WSVOH2AE can be selected;

- Signal Type Requirements: It is best suited for scenarios requiring simultaneous output of 4-20mA and 0-10V signals (software-switchable); for pure current or pure voltage output scenarios, dedicated modules (e.g., IS210WSVIH1AE current input module) can be selected;

- Accuracy and Environment: Applicable to non-hazardous areas with control accuracy requirements ≤±0.1% FS and ambient temperature of 0℃-60℃; for high-temperature (>60℃) or explosion-proof scenarios, upgraded versions (e.g., IS210WSVOH1AE-EX explosion-proof type) must be selected.

(II) Peripheral Configuration Recommendations

- Actuator Adaptation: For 4-20mA output, the GE Fisher DVC6200 intelligent valve positioner (load impedance 250Ω) is preferred; for 0-10V output, it is adapted to the Siemens MM440 frequency converter (input impedance 10kΩ);

- Power Supply Configuration: Must be matched with Mark VIe standard redundant power modules (e.g., IS200PWRCH1A, 24V DC/10A) to ensure stable power supply; for non-Mark VIe systems, compatibility can be achieved through protocol converters (e.g., MOXA MGate), but it is recommended to use it in the Mark VIe system first to ensure complete functionality;

- Wiring Specifications: Twisted shielded cables (cross-sectional area 0.75mm²) should be used for analog output cables; the shield layer should be grounded at one end (ground resistance ≤1Ω); the distance from power cables should be ≥300mm to avoid electromagnetic interference; the cable length should be ≤500m (for 4-20mA) and ≤100m (for 0-10V) to avoid signal attenuation.

(III) Installation and Commissioning Notes

- Installation Specifications: The module must be installed in a Mark VIe standard I/O cabinet (e.g., IC698CAB100), with a distance of ≥200mm from frequency converters and contactors to avoid heat dissipation impact; the rack ground resistance should be ≤4Ω to ensure isolation effect;

- Parameter Configuration: Configure the signal type (current/voltage) of each channel, output range (e.g., 4-20mA corresponding to 0-100% valve position), and fail-safe value via ControlST software; the module must be preheated for 30 minutes before calibration to ensure stable temperature drift;

- Commissioning and Verification:

- Accuracy Test: Input digital commands (0%, 50%, 100%) and measure the output value with a standard ammeter/voltmeter; the error should be ≤±0.05% FS;

- Fault Test: Simulate a channel short circuit (connect a 2Ω resistor) to confirm that the module triggers short-circuit protection and reports the fault; simulate a power failure to check if the output switches to the preset safe value;

- Redundancy Test: Under rack-level redundancy configuration, disconnect the power supply of the main rack and confirm that the module in the standby rack takes over the output within 1ms without signal interruption.