Description

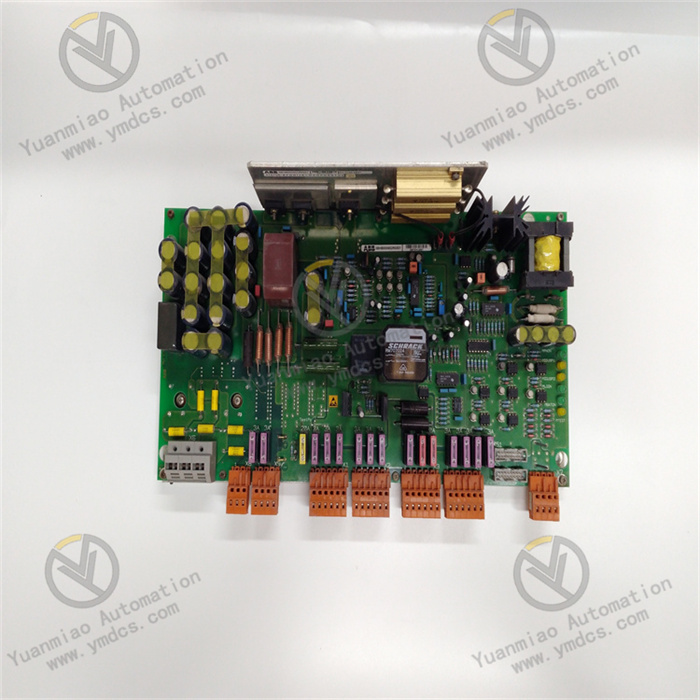

ABB S-073N 3BHB009884R5211 Industrial Controller Module

Functional Features

- Flexible Network Connectivity

Supports logically independent dual Profibus DP buses, enabling electrical interface backup or single-device access to dual redundant bus systems. It also supports point-to-point network connections, allowing multi-segment Profibus DP bus connections on fiber-optic buses with dual optical port chain networks. Additionally, it features dual optical ports for dual-fiber ring network redundancy: if a fiber fault occurs, the system rebuilds the network within 10ms. - Multi-Protocol Support

Compatible with industrial communication protocols such as Ethernet, serial communication (RS-232/RS-485), Modbus, and Profibus, facilitating data exchange and remote control with host computers and other automation devices. - Robust Protection Functions

Built-in safety features including overload protection, short-circuit protection, and undervoltage protection effectively prevent motor damage and accidents. It also offers 4000V lightning protection, 1.5A overcurrent protection, and 600W surge protection to ensure stable operation in harsh environments. - Plug-and-Play

Utilizes the company’s proprietary ring network protocol Ci-ring, which requires no root node setup. It enables rapid network ring formation and disconnection, simplifying installation and debugging for users.

Technical Parameters

- I/O Configuration: Provides 16 digital input channels, supporting multiple digital and analog input/output options.

- Power Requirements: Power voltage may be 24V DC or 120/240V AC, depending on the application.

- Operating Temperature Range: -20°C to 70°C.

- Protection Level: IP30, suitable for harsh industrial environments.

- Dimensions: Approximately 100mm×100mm×50mm (for reference only).

- Weight: Approximately 1.5kg.

- Mounting Methods: Supports panel mounting or DIN rail mounting.

Application Scenarios

- Industrial Automation: Used for production line control, robot control, sensor data acquisition, etc.

- Building Automation: Controls devices in building management systems, such as HVAC and lighting systems.

- Energy Management: Monitors and controls generators, power grid equipment, etc., to improve energy system efficiency and stability.

- Environmental Monitoring: Collects and outputs analog signals of environmental parameters such as meteorological data, water quality, and air quality.

- Power Systems: Applied in power plants, substations, and other settings.

General Operation Guide for ABB S-073N 3BHB009884R5211

Hardware Installation

- Location Selection: Choose an installation location that meets its operating environment requirements (e.g., temperature, humidity, protection level), ensuring no strong electromagnetic interference. The module’s operating temperature range is -20°C to 70°C, with an IP30 protection level, suitable for harsh industrial environments.

- Mounting Methods:

- Panel Mounting: Drill holes in the panel according to the module’s dimensions and secure the module.

- DIN Rail Mounting: Clip the module onto the DIN rail and ensure it is firmly fastened.

- Electrical Connections:

- Connect the power supply with the correct voltage (24V DC or 120/240V AC) as required.

- Connect external devices (e.g., PLCs, sensors, actuators) to the module via corresponding interfaces (e.g., Profibus DP, Ethernet, serial communication), ensuring secure wiring and compliance with electrical safety standards.

Software Configuration and Parameter Setting

- Configuration Tool Preparation: Ensure compatible configuration software (typically provided by ABB) is installed.

- Project Creation: Open the configuration software, create a new project, and select the device type as ABB S-073N 3BHB009884R5211.

- Network Configuration:

- For Profibus DP bus connections, set parameters such as station address and baud rate.

- For Ethernet connections, set IP address, subnet mask, gateway, etc., to ensure normal communication with other devices.

- Functional Configuration:

- Configure I/O functions based on the application scenario. For example, set filter time and input signal type (PNP/NPN) for digital input channels; configure output modes (e.g., push-pull output, relay output) for digital output channels. For modules supporting analog I/O, set parameters such as analog range, accuracy, and filtering.

- Protection Parameter Setting: Set built-in overload, short-circuit, and undervoltage protection parameters according to connected devices and system requirements to ensure equipment and system safety.

System Debugging and Operation

- Hardware Inspection: Before powering on, recheck hardware connections (power supply, communication cables, I/O devices) to ensure no looseness or short circuits.

- Power-On Test: Apply power to the module and observe indicator lights. The power indicator should light up; if there is a communication connection, the corresponding communication indicator should light or flash according to the communication status. If indicators are abnormal, refer to the module manual for troubleshooting.

- Software Download and Activation: Download the configured project to the module and activate the configuration to make the module operate according to the set parameters and functions.

- Functional Testing:

- Send test signals or simulate actual working conditions to check I/O functions. For example, input different voltage levels to digital input channels to see if the module correctly identifies them and displays corresponding statuses in the configuration software; control digital output channels to output high/low voltages and check if external devices act as expected. For analog I/O channels, input different analog signals to verify accurate acquisition and output.

- On-Site Operation and Monitoring: After installing the module in the industrial field, put it into operation. Use configuration software or a host monitoring system to real-time monitor the module’s status, including I/O data, device temperature, power status, etc. If anomalies are detected, promptly diagnose and resolve faults.

Hardware Replacement (Taking CPU Unit Replacement as an Example)

- Library Insertion: Ensure the library containing the hardware type to be added is inserted into the project and connected to the controller.

- Replacement Process: Right-click the unit to be replaced, select "Replace Unit" to open the "Replace Unit" dialog box. During replacement, the system retains settings and connections, as well as existing subtrees and units. For example, replacing a CPU with a similar one can be completed without connection or data loss.

Related Products

ABB 500MBA02 1MRB150003R000/B Control Module

ABB 5SHX14H4502 3BHB003230R0101 IGCT Module

ABB PM856AK01 3BSE066490R1 | AC 800M Processor Unit Kit

ABB EI813F 3BDH000022R1 | AC 800F Ethernet Fieldbus Module - 10BaseT

ABB CI868K01 3BSE048845R1 | AC 800M Communication Interface Kit