Description

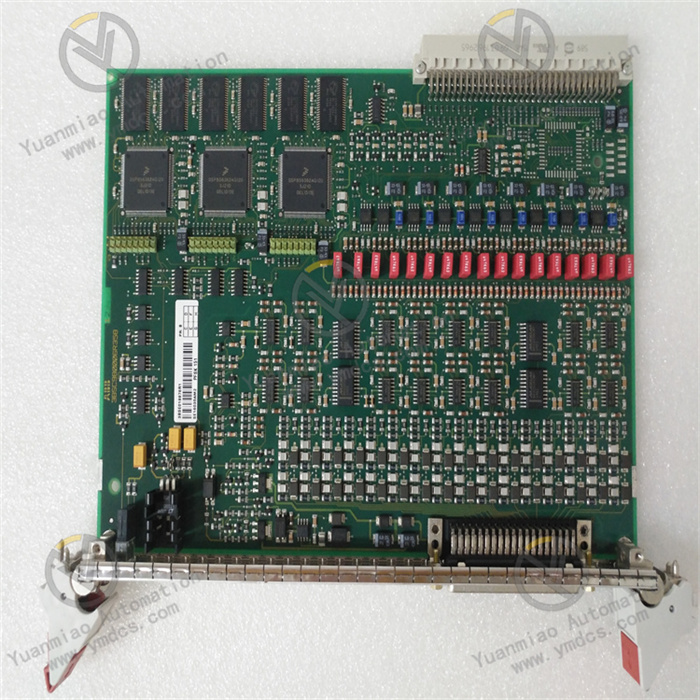

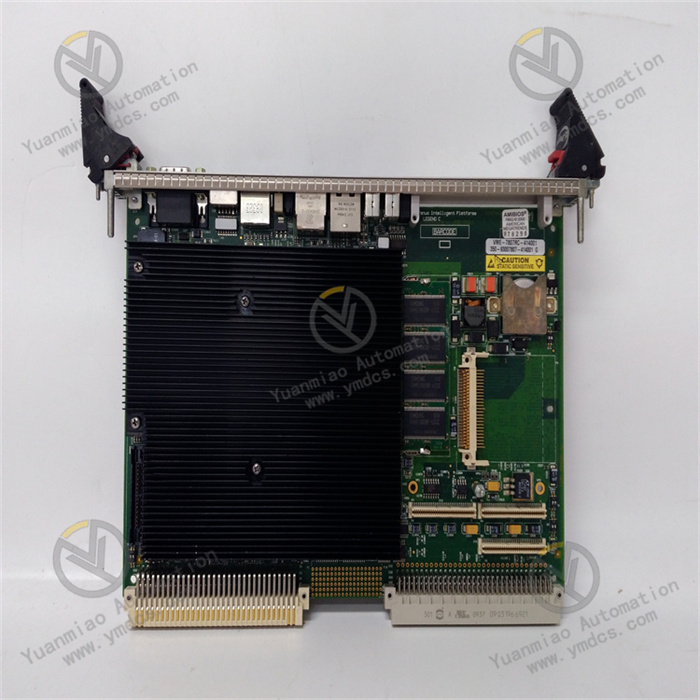

ABB CI868K01 3BSE048845R1

I. Basic Product Information

Series Affiliation

It belongs to the ABB AC 800M Controller Series and serves as a high-performance communication interface module. Specifically designed for complex fieldbus and industrial Ethernet communication in industrial automation systems, it supports multi-protocol integration and high-speed data interaction.

Core Functions

Multi-Protocol Communication Capability

Supports mainstream industrial protocols, including:

- PROFINET (real-time communication for high-demand automation scenarios)

- Ethernet/IP (industrial protocol based on Ethernet, compatible with Rockwell systems)

- Modbus TCP (Ethernet version of Modbus for device networking)

- Some models may support OPC UA (industrial IoT standard for secure data interaction).

It can act as a master station or slave station to connect devices such as PLCs, DCS systems, smart instruments, and robots.

High-Speed Data Interaction

- Equipped with a high-performance processor, it supports real-time data transmission (latency as low as microseconds), suitable for control systems requiring fast response (e.g., motion control, process automation).

- Enables data mapping and protocol conversion to achieve seamless communication between devices with different protocols.

System Integration and Configuration

- Parameters can be configured, diagnosed, and firmware upgraded via ABB Control Builder M software.

- Supports redundant configuration (e.g., hot standby for dual Ethernet interfaces) to enhance system reliability.

Application Scenarios

- Industries: Widely used in fields requiring high communication speed and real-time performance, such as automotive manufacturing, electronics & semiconductors, precision machinery, energy management, and smart factories.

- Typical Scenarios:

- Equipment networking in automated production lines (e.g., communication between robots, PLCs, and sensors).

- Integration of distributed control systems (DCS) in industrial Ethernet architectures.

- Industrial IoT (IIoT) data collection and cloud platform docking based on OPC UA.

II. Technical Parameters

| Parameter Category | Detailed Information |

|---|---|

| Communication Protocols | PROFINET IO, Ethernet/IP, Modbus TCP, OPC UA (optional) |

| Interface Types | - Physical: 2×RJ45 Ethernet interfaces (supporting redundancy) - Electrical: IEEE 802.3 (10/100/1000 Mbps) |

| Data Transfer Rate | Ethernet: 10/100/1000 Mbps (auto-adaptive) |

| Power Supply | DC 24 V (±10%), power consumption: ~8-12 W |

| Operating Temperature | -40°C to +70°C (industrial-wide temperature design for harsh environments) |

| Protection Level | IP20 (suitable for installation in control cabinets) |

| Certification Standards | CE, UL, CSA, PROFINET conformance certification, OPC UA compliance certification |

| Redundancy Support | - Dual Ethernet interface redundancy - PROFINET ring topology support (requires switch) |

| Configuration Tools | ABB Control Builder M, supports GSDML files (PROFINET slave configuration) |

III. Product Features and Advantages

1. High Performance and Real-Time Capability

- Gigabit Ethernet Support: Meets large-data-volume transmission needs (e.g., HD video monitoring, robot trajectory data).

- Hard Real-Time Communication: Achieves microsecond-level synchronization via protocols like PROFINET, suitable for motion control (e.g., servo systems).

2. High-Reliability Design

- Hardware Redundancy: Dual network ports support link aggregation or redundant switching to avoid communication interruptions due to single-point failures.

- Electrical Isolation: Built-in isolation modules (isolation ≥2500 Vrms) with strong anti-electromagnetic interference (EMI) capabilities.

- Watchdog Mechanism: Prevents software crashes and automatically restores communication links.

3. Flexibility and Ease of Use

- Plug-and-Play: Supports automatic topology recognition (PROFINET) to reduce configuration time.

- Visual Diagnosis: Module equipped with status indicator lights (PWR, LINK, ACT, ERR) to display power, link, data transmission, and fault status in real time.

- Online Upgrades: Supports firmware updates without downtime, reducing maintenance costs.

4. Industrial IoT Integration

- Native support for the OPC UA protocol, enabling direct docking with industrial cloud platforms (e.g., ABB Ability™) for remote device monitoring and data analysis.

- Supports IT/OT convergence architectures to facilitate factory digital transformation.

IV. Fault Diagnosis and Maintenance

1. Indicator Light Diagnosis

| Indicator | Normal Status | Abnormal Status and Possible Causes |

|---|---|---|

| PWR | Green, steady on | - Off: Power not connected, cable failure, or module power damage - Flashing: Unstable voltage (excessive ripple) |

| LINK | Green, steady on | - Off: Ethernet cable not connected or interface damaged - Red: Link error (e.g., speed/duplex mismatch) |

| ACT | Green, flashing | - Steady on/off: No data transmission (possible configuration error or slave unresponsiveness) |

| ERR | Off | - Red, steady on: Module hardware failure (e.g., chip damage) - Flashing: Communication timeout, configuration error, or protocol incompatibility |

2. Common Fault Troubleshooting Steps

- Physical Layer Check:

- Confirm normal power voltage; replace cables or power modules to eliminate power issues.

- Check Ethernet cable integrity (recommended CAT6) and test RJ45 connector contact quality.

- Ensure device IP addresses are in the same subnet without conflicts (test connectivity via ping).

- Software Configuration Verification:

- Verify that the PROFINET device name matches the actual configuration (must be assigned via PLC or gateway).

- Check GSDML file version compatibility with the slave device and re-import the latest file.

- Confirm Modbus TCP register addresses and function codes match the slave protocol.

- Advanced Diagnostic Tools:

- Use Wireshark for Ethernet packet analysis to troubleshoot protocol parsing errors or data anomalies.

- Read error codes (e.g., "PROFINET IO communication interrupted") via ABB Control Builder M's "Diagnostics Window" to locate slave faults.

3. Maintenance Recommendations

- Regular Inspections: Check module heat dissipation and clean dust every six months to ensure good ventilation.

- Redundancy Testing: Simulate single-network-port failures annually to verify normal redundant switching functionality.

- Firmware Management: Monitor firmware updates on ABB's official website and upgrade promptly to fix vulnerabilities or add new features.

- Documentation Backup: Save module configuration files (.xml or .ini), slave GSDML files, and IP address plans for quick system recovery.

V. Typical Application Architecture

plaintext

[ABB AC 800M Controller] ↔ [CI868K01 Module] ↔ [Industrial Ethernet] ↔ {

[PROFINET Slave Devices (e.g., Siemens ET 200SP)]

[Ethernet/IP Devices (e.g., Rockwell CompactLogix PLC)]

[Modbus TCP Smart Instruments]

[OPC UA Server (Connected to Cloud Platform)]

}Explanation: The module acts as a communication gateway to enable unified access and data interaction for devices with different protocols, supporting real-time transmission of field data to SCADA systems or cloud platforms.