Description

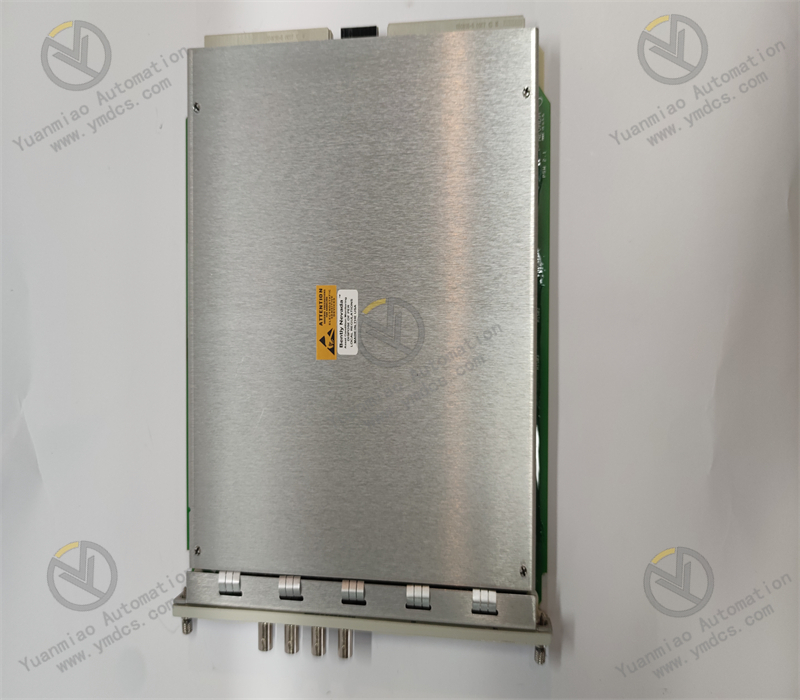

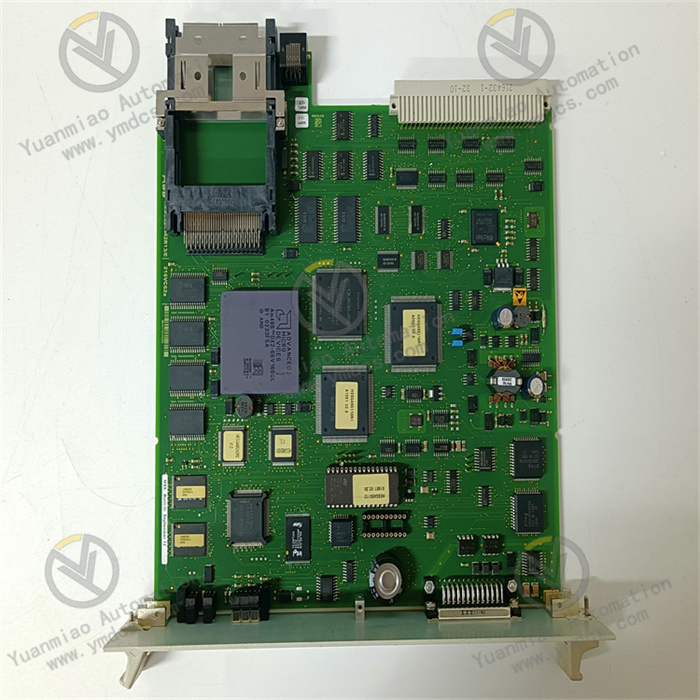

Functional Features Vibration Monitoring: It is mainly used to monitor the vibration levels of rotating mechanical equipment such as engines, pumps, compressors, etc., and to evaluate the operating status of the equipment based on the monitored data. Multi-channel Monitoring: It supports multi-channel vibration monitoring, and can simultaneously monitor the vibration conditions of multiple devices or multiple bearings. Real-time Monitoring and Analysis: It has a real-time monitoring function, which can continuously monitor the equipment vibration and provide real-time data feedback. It may also support the spectrum analysis function to perform spectrum analysis on the vibration data to identify fault frequencies and abnormal vibration patterns. Alarm Function: When the equipment vibration monitored exceeds the set threshold, the alarm function will be triggered to remind the operator of the abnormal situation of the equipment. Data Recording: It has a historical data recording function, which can record the vibration data and save the historical records for convenient subsequent analysis and fault diagnosis. Communication Function: It supports communication with other monitoring systems or data acquisition systems, facilitating data sharing and integration. Industrial-grade Design: It adopts a durable industrial-grade design and is suitable for long-term use in harsh industrial environment conditions.

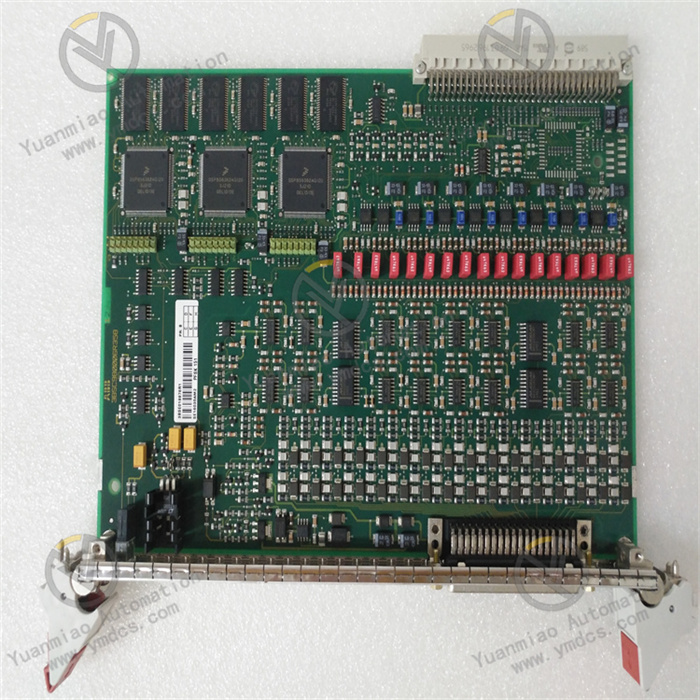

Technical Specification Parameters Input Signals: It can accept types of signals such as acceleration, speed, and absolute shaft vibration, and is compatible with sensors such as Bentley proximity eddy current sensors like 330400, 330500, speed and acceleration sensors, and various composite sensors. Number of Channels: It usually supports multiple channels (the specific number may vary slightly depending on the model) to achieve multi-channel monitoring. Measurement Range: According to different measurement parameters (such as acceleration, speed, displacement, etc.), there are corresponding measurement ranges. For example, the acceleration measurement range may be from ±5g to ±50g, etc. (subject to the actual model). Accuracy: It has a high measurement accuracy. For example, the measurement accuracy of the vibration amplitude can reach ±1% or higher. Output Signals: Generally, it provides standard analog output signals (such as 4 - 20mA) for connection to other control devices or display devices. It may also have digital output interfaces (such as RS - 485, etc.) for communication with other systems.

Application Areas Power Industry: It is used to monitor the vibration conditions of large rotating equipment such as steam turbines, generators, and exciters to ensure the stable operation of power production. Petrochemical Industry: It conducts vibration monitoring on equipment such as compressors, pumps, and fans to promptly detect potential equipment faults and avoid production interruptions or safety accidents caused by equipment failures. Metallurgical Industry: It is applied to equipment such as blast furnace blowers and steel rolling mills, which helps to detect abnormal equipment vibration in advance and reduce equipment maintenance costs and downtime. Other Industrial Fields: For example, the monitoring of aero engines in the aerospace field, and in various industrial scenarios where rotating mechanical equipment is used, this module can effectively monitor and analyze the equipment vibration.

Common Faults and Solutions Abnormal Data Possible Reasons: Sensor failure, connection line problems, internal circuit failure of the module. Solutions: Check whether the sensor is working properly, and test by replacing the sensor if necessary; check whether the connection line is loose, damaged, or short-circuited, and repair or replace the line if there are problems; if the above are normal, contact professional maintenance personnel to check and repair the internal circuit of the module. False Alarm Triggering Possible Reasons: Unreasonable threshold setting, external interference, short-term fluctuations of the equipment itself. Solutions: Re-evaluate and reasonably set the alarm threshold to ensure it is in line with the actual operation of the equipment; check whether there are external interference sources such as strong electromagnetic interference in the surrounding environment, and take corresponding shielding or isolation measures; observe the operation status of the equipment to determine whether it is caused by the short-term fluctuations of the equipment itself. If so, appropriately adjust the alarm delay time to avoid false alarms. Communication Fault Possible Reasons: Incorrect communication parameter setting, damaged communication interface, communication line failure. Solutions: Check the communication parameter setting of the module to ensure it is consistent with other connected devices; check whether the communication interface is physically damaged and replace it if necessary; check the communication line and repair or replace the faulty line.