Description

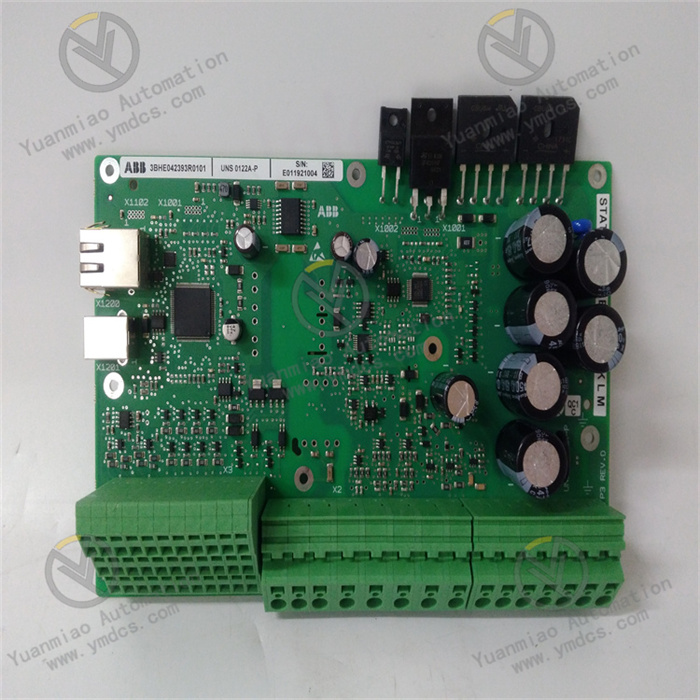

ABB 5SHX14H4502 3BHB003230R0101

Brand: ABB

Model: 5SHX14H4502

Order Number: 3BHB003230R0101

Type: High-voltage thyristor module (belongs to ABB's power semiconductor product line, commonly used in power electronics converter devices).

Application Scenarios:

- High-voltage direct current (HVDC) transmission, flexible alternating current transmission systems (FACTS).

- Industrial frequency converters, motor drive systems (e.g., mill drives, fan and pump control).

- Power system reactive power compensation (SVC/SVG), solid-state circuit breakers (SSCB), etc.

- Rated Voltage: Typically suitable for high-voltage scenarios at the kV level (specifically refer to the technical manual, e.g., 4500V class).

- Current-Carrying Capacity: Can withstand high pulse currents and continuous currents (e.g., peak currents in the thousands of amperes), adapting to high-power energy conversion requirements.

- High Reliability: Adopts ceramic packaging or press-fit structures, with excellent electrical insulation and thermal conductivity, suitable for long-term full-load operation.

- Trigger Characteristics: Supports high-precision gate trigger control, enabling precise adjustment of the conduction timing through external signals (e.g., pulse transformers).

- Switching Speed: Suitable for medium-to-high-frequency switching scenarios (e.g., in the hundreds of Hz range), meeting the high dynamic response requirements of power electronics systems.

- Efficient Heat Dissipation: Built-in large-area metal substrates or water-cooling channels, combined with external radiators or water-cooling systems, ensure junction temperature is controlled within a safe range (e.g., ≤125°C).

- Mechanical Strength: Modular design facilitates installation and replacement, supporting bolt-fixed or press-fit mounting, and adapting to vibrating environments.

- Built-in Protection: Some models integrate voltage/current sensors or temperature monitoring elements, supporting overheat and overcurrent warnings.

- Fault Tolerance: System reliability is enhanced through redundancy design or parallel configuration (needs to be combined with specific application scenarios).

- Multi-Module Series/Parallel Connection: Can be combined into valve stacks to meet higher voltage or current rating requirements (e.g., HVDC converter valves).

- Control System Adaptability: Compatible with ABB's PCS 600 series controllers or third-party control platforms to achieve closed-loop control.

| Parameter | Description |

|---|

| Rated off-state repetitive voltage | 4500 V (VDRM/VRRM) |

| Average on-state current | 1400 A (IT(AV), under rated conditions) |

| Non-repetitive peak surge current | 30 kA (ITSM, 8/20μs pulse) |

| Gate trigger current/voltage | Typical values: Igt ≤ 200 mA, Vgt ≤ 5 V |

| Junction temperature range | -40°C ~ +125°C (Tj) |

| Packaging type | Press-fit ceramic packaging (e.g., planar structure) |

| Dimensions | Diameter approx. 120 mm, thickness approx. 40 mm (refer to specific specifications) |

| Certifications | Compliant with IEC 60747-6, IEEE standards; may have UL, CE, etc., certifications |

- HVDC Transmission Systems: As a core component of converter valves, enabling AC/DC power conversion (e.g., submarine cable transmission connecting onshore grids with offshore wind power).

- Industrial Variable Frequency Drives: In drive systems for large motors (e.g., synchronous and asynchronous motors) in steel, papermaking, etc., to achieve speed and torque control.

- Power System Stabilization Devices: Used in SVC (static var compensators) or STATCOM (static synchronous compensators) to regulate grid reactive power and improve power quality.

- Driving and Control Modules: Such as ABB's 5SDD series trigger units for generating gate pulse signals.

- Cooling Systems: Water-cooled radiators (e.g., ABB water-cooled plates) or air-cooled devices to ensure module heat dissipation efficiency.

- Protection Components: Surge arresters, fast fuses (e.g., ABB semiconductor protection fuses) to prevent overvoltage/overcurrent damage.

- Mechanical Installation:

- Ensure close contact between the module and radiator, using thermal grease or gaskets to reduce thermal resistance.

- Tighten bolts to the torque specified in the manual (e.g., 25 N·m) to avoid stress damage to the packaging.

- Electrical Connections:

- Use copper busbars or large-section cables for main circuit wiring to reduce line impedance and heat generation.

- Gate signal wires should be routed independently to avoid electromagnetic interference (EMI) affecting trigger reliability.

- Condition Monitoring:

- Regularly inspect the module surface for cracks or burn marks, and check the cooling system (e.g., water flow, fan operation status).

- Monitor module temperature with an infrared thermometer to ensure the junction temperature does not exceed the rated value.

- Parameter Testing:

- Use specialized testing equipment (e.g., thyristor testers) to measure parameters such as forward voltage drop and off-state resistance to assess device aging.

- Fault Handling:

If the module is damaged (e.g., breakdown, open circuit), replace it as a whole and check the drive circuit and system protection functions for abnormalities.

Related Products

ABB SYN5201a-Z,V217 3BHB006714R0217 | Synchronizing and Paralleling Equipment

ABB 5SHX2645L0002 3BHB012961R0001 IGCT Module

ABB REF545KC133AAAA Protective Relay Module

ABB 500BIO01 1MRB150005R1/J Inverter Control Unit

ABB CTI21-P Ex 3BDH000741R1 Temperature Input Module

![]()