Description

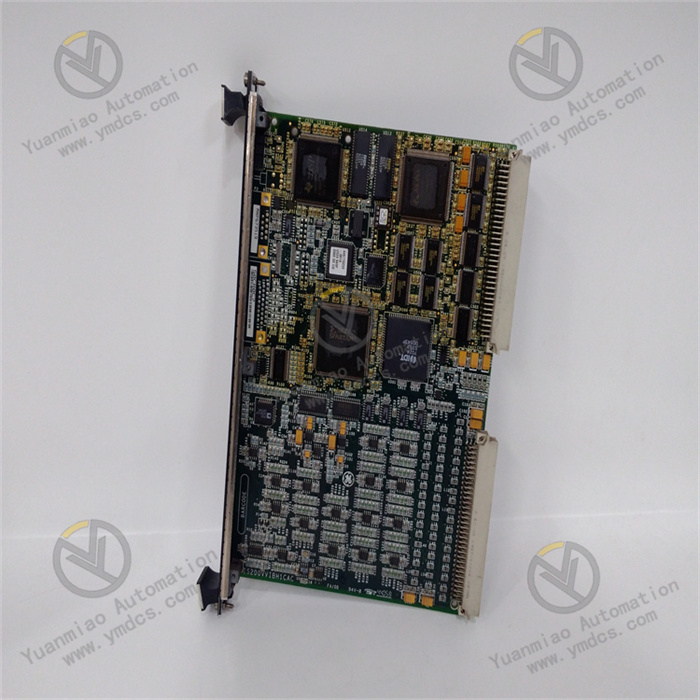

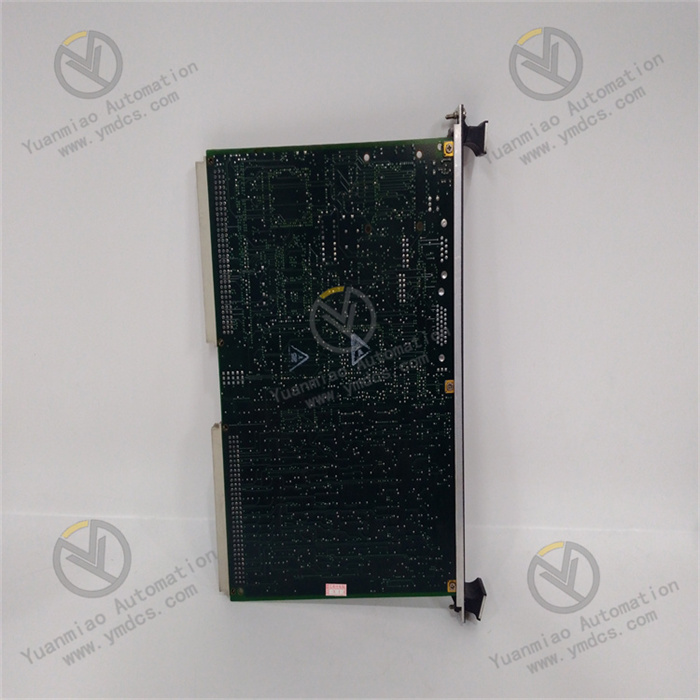

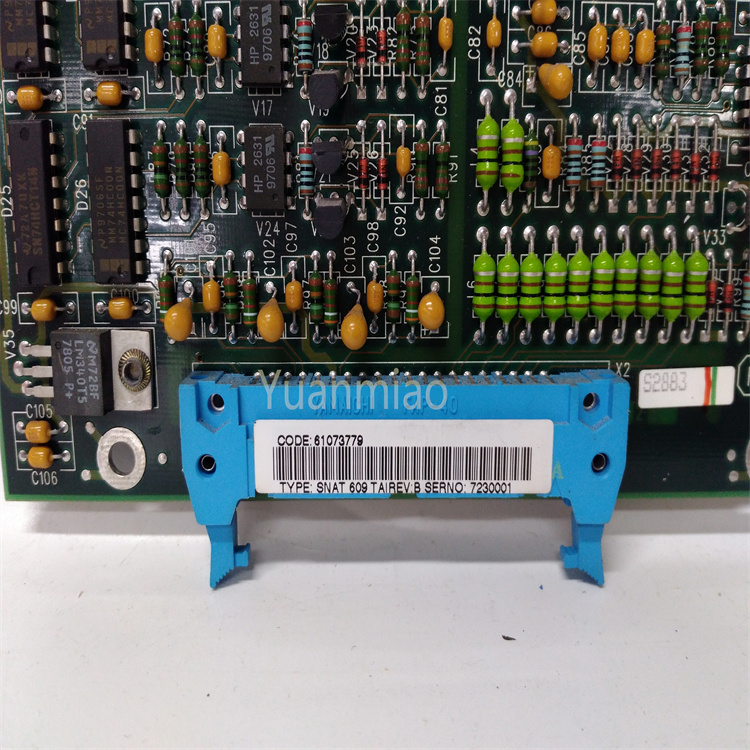

GE IS200VVIBH1CAC

I. Product Overview

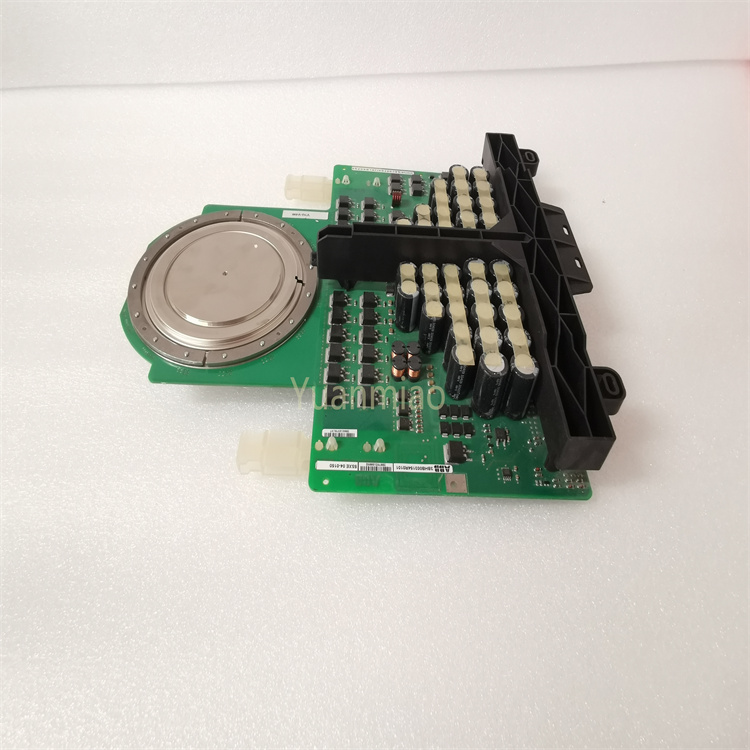

GE IS200VVIBH1CAC is a core vibration monitoring module in the Mark VIe series of industrial control systems. It is specifically designed for vibration status monitoring and fault early warning scenarios of key rotating mechanical equipment such as gas turbines, steam turbines, water turbines, centrifugal compressors, and fans. As a key sensing unit for rotating machinery health management, this module undertakes core functions including high-precision collection, real-time analysis, feature extraction, and alarm triggering of vibration signals. It can be directly connected to front-end sensing devices such as acceleration sensors, velocity sensors, and eddy current sensors to accurately capture vibration abnormalities during equipment operation, providing highly reliable data support for equipment preventive maintenance, fault tracing, and safe operation.

II. Functional Features

Multi-Channel High-Precision Vibration Collection: The module integrates 4 independent vibration collection channels. Each channel supports the measurement of three vibration parameters: acceleration (0-50g), velocity (0-200mm/s), and displacement (0-500μm). It can be flexibly configured via software according to the type of front-end sensor (piezoelectric acceleration sensor, magnetoelectric velocity sensor, eddy current displacement sensor). Equipped with a 24-bit high-precision A/D converter, the sampling rate reaches 12.8kHz, and the vibration measurement accuracy is ±0.1%FS. It can accurately capture vibration signals in the frequency range from low frequency (0.1Hz) to high frequency (10kHz), and effectively identify vibration characteristics of typical faults such as rotor unbalance, misalignment, bearing wear, and abnormal gear meshing.

Multi-Level Signal Conditioning and Anti-Interference Design: It adopts a three-level signal conditioning architecture of "Sensor Level - Channel Level - Module Level". Each channel has a built-in low-noise preamplifier, programmable gain circuit, and wide-band filter network. The preamplifier can amplify the weak signal (μV level) output by the sensor to the standard range; the programmable gain supports adjustable 1-1000 times; the filter network supports high-pass (0.1Hz-1kHz), low-pass (1kHz-10kHz), band-pass, and notch filtering (50Hz/60Hz power frequency suppression), which can accurately filter electromagnetic interference and environmental noise in industrial sites. The module adopts an overall photoelectric isolation design, with an isolation voltage of 2500V DC between channels and 1500V DC between the module and the system bus. Its anti-interference capability complies with the IEC 61000-4-2/3/4 standards.

Real-Time Data Processing and Feature Extraction: Equipped with a high-performance digital signal processor (DSP), it supports multi-dimensional data processing in the time domain, frequency domain, and trend domain. Time-domain analysis can calculate key parameters such as vibration peak-to-peak value, effective value, peak value, average value, kurtosis, and skewness in real time; frequency-domain analysis realizes 1024-point spectrum analysis through Fast Fourier Transform (FFT), which can extract characteristic frequency components such as 1x frequency, 2x frequency, and 3x frequency to identify faults such as rotor unbalance, misalignment, and resonance; trend analysis can record historical change curves of key parameters, supporting adjustable sampling periods from 1 minute to 24 hours, with a data storage capacity of 16GB, which can meet the needs of historical data tracing for more than 1 year.

Flexible Alarm Mechanism and Fault Early Warning: It supports a four-level alarm mechanism (Prompt, Early Warning, Alarm, Danger). Each channel can independently configure the alarm threshold, hysteresis value, and response time for each level. The threshold setting accuracy reaches 0.01μm (displacement), 0.01mm/s (velocity), and 0.01g (acceleration). When an alarm is triggered, the module can output alarm signals through three methods: dry contacts (2 independent outputs), communication protocols, and LED indicators. At the same time, it automatically records the original vibration waveform, spectrum data, and key parameters at the time of the alarm, providing a complete data chain for fault tracing. It supports an alarm suppression function, which can set the alarm shielding time (adjustable from 0 to 600s) for special working conditions such as equipment start-up and shutdown to avoid false alarms.

Redundant Configuration and Hot-Swap Capability: It supports the dual-machine hot-standby redundant configuration of the Mark VIe system. The module can be connected to the redundant I/O network as a master/slave node. The data synchronization delay between the master and slave modules is ≤1ms. When the master module fails, the slave module can seamlessly take over the work to ensure uninterrupted vibration monitoring. It adopts a standardized guide rail installation structure and supports live hot-swap operation. The built-in contact protection circuit during plugging and unplugging can prevent arc generation and avoid damage to the module and front-end sensors. The hot-swap replacement time is ≤30 seconds, which greatly shortens the maintenance downtime.

- Convenient System Integration and Remote Operation & Maintenance: It supports GE's dedicated Genius Bus communication protocol and the standard Modbus TCP/IP protocol, and is equipped with 2 RJ45 Ethernet redundant communication interfaces with a communication rate of 100Mbps. It can be seamlessly connected to the Mark VIe control system and third-party SCADA platforms (such as GE Proficy iFIX, Wonderware Intouch). Through the GE Proficy Machine Edition software, remote parameter configuration (channel type, filter parameters, alarm threshold, etc.), firmware upgrade, and fault diagnosis of the module can be realized. It supports remote upload and analysis of vibration waveforms and spectrum data, without the need for on-site connection of debugging equipment, improving the efficiency of operation and maintenance.

III. Technical Parameters

| Parameter Category | Parameter Name | Specific Parameters | Unit |

|---|---|---|---|

| Basic Parameters | Model | GE IS200VVIBH1CAC | - |

| Product Type | Vibration Monitoring Module | - | |

| Overall Dimensions (L×W×H) | 160×80×120 | mm | |

| Weight | Approximately 0.9 | kg | |

| Acquisition Performance Parameters | Number of Channels | 4 channels, independent isolation | Channel |

| Supported Sensor Types | Piezoelectric acceleration sensor, magnetoelectric velocity sensor, eddy current displacement sensor | - | |

| Measurement Range | Acceleration: 0-50g; Velocity: 0-200mm/s; Displacement: 0-500μm | g/mm/s/μm | |

| Measurement Accuracy | ±0.1%FS | - | |

| Sampling Rate | 12.8kHz, independent sampling per channel | kHz | |

| Frequency Response Range | 0.1Hz-10kHz | Hz | |

| A/D Converter Accuracy | 24-bit | Bit | |

| Signal Processing Parameters | FFT Points | 1024 points | Point |

| Time-Domain Parameters | Peak-to-peak value, effective value, peak value, average value, kurtosis, skewness | - | |

| Filtering Methods | High-pass, low-pass, band-pass, notch (50Hz/60Hz) | - | |

| Gain Range | 1-1000 times, programmable and adjustable | Time | |

| Alarm and Storage Parameters | Alarm Levels | 4 levels (Prompt, Early Warning, Alarm, Danger) | - |

| Alarm Output | 2 dry contacts, rated at AC 250V/5A | V/A | |

| Data Storage Capacity | 16GB, supporting cyclic coverage of historical data | GB | |

| Trend Sampling Period | 1 minute-24 hours, adjustable | - | |

| Power and Communication Parameters | Power Supply Voltage | DC 24V±10%, supporting redundant power supply | V DC |

| Operating Current | ≤150mA at no load; ≤500mA at full load | mA | |

| Communication Interfaces | 2 RJ45 Ethernet ports (redundant) | - | |

| Supported Communication Protocols | Genius Bus, Modbus TCP/IP | - | |

| Environmental and Reliability Parameters | Operating Temperature Range | -40~70 | ℃ |

| Storage Temperature Range | -40~85 | ℃ | |

| Relative Humidity | 5%-95% (no condensation) | % | |

| Protection Level | IP20 (panel) | - | |

| Mean Time Between Failures (MTBF) | ≥200,000 | Hour |

IV. Working Principle

The working principle of the GE IS200VVIBH1CAC vibration monitoring module revolves around the core link of "signal collection - conditioning processing - data calculation - alarm judgment - data interaction". Combined with redundant protection and fault diagnosis mechanisms, it realizes high-precision monitoring and early warning of the vibration status of key rotating equipment. The specific process is as follows:

- Redundant Power Supply and System Initialization:The module is connected to a DC 24V redundant power supply. After rectification, filtering, and voltage stabilization through the built-in power management circuit, a stable DC voltage is output to power the internal CPU, DSP, A/D converter, isolation circuit, and other units of the module. The power management circuit monitors the status of the two input power supplies in real time. When one power supply fails (voltage lower than 21.6V or higher than 26.4V), it immediately switches to the other power supply, with a switching time of ≤1ms to ensure continuous operation of the module. After the module is powered on, it executes the initialization program to self-check the status of the CPU, DSP, A/D converter, communication interface, and channel circuit. After initialization, the system status is fed back through the front-end LED indicators. In case of a fault, the corresponding fault code is output and uploaded to the controller.

- Vibration Signal Collection and Conditioning:The front-end sensor (acceleration/velocity/displacement sensor) converts the mechanical vibration of the rotating equipment into an electrical signal, which is connected to the 4 independent collection channels of the module. Each channel has a built-in three-level signal conditioning unit: the low-noise preamplifier amplifies the μV-level weak signal to the standard voltage range (0-5V); the programmable gain circuit automatically adjusts the gain (1-1000 times) according to the sensor sensitivity to ensure that the signal amplitude matches the input range of the A/D converter; the filter network filters interference signals according to preset parameters, such as suppressing 50Hz/60Hz power frequency interference through notch filtering and filtering high-frequency noise through low-pass filtering. The conditioned signal is sent to the A/D converter after being isolated by the photoelectric isolator, realizing electrical isolation between the on-site side and the internal circuit of the module, with an isolation voltage of 2500V DC.

- Data Conversion and Multi-Dimensional Calculation:The conditioned analog signal is sent to the 24-bit A/D converter, which converts it into a digital signal at a sampling rate of 12.8kHz. Each channel samples independently to avoid interference between channels. The digital signal is sent to the DSP for real-time calculation: time-domain calculation uses statistical analysis algorithms to calculate parameters such as peak-to-peak value, effective value, and kurtosis, reflecting the intensity and waveform characteristics of the vibration signal; frequency-domain calculation converts the time-domain signal into a frequency-domain signal through 1024-point FFT to extract characteristic frequency components and identify typical faults such as rotor unbalance (abnormal 1x frequency), misalignment (abnormal 2x frequency), and bearing failure (abnormal characteristic frequency); trend calculation records key parameters according to a preset period (1 minute-24 hours), forms a historical trend curve, and stores it in the 16GB memory.

- Alarm Judgment and Signal Output:The CPU calls the time-domain and frequency-domain parameters calculated by the DSP in real time and compares them with the preset four-level alarm thresholds (Prompt, Early Warning, Alarm, Danger). When the parameter reaches the "Prompt" threshold, only the prompt information is uploaded through communication; when it reaches the "Early Warning" threshold, the early warning indicator of the corresponding channel is lit and the early warning information is uploaded; when it reaches the "Alarm" threshold, the dry contact alarm output is triggered, the alarm indicator is lit, and the alarm information is uploaded; when it reaches the "Danger" threshold, the high-priority alarm output is triggered, and the interlock signal (optional) is uploaded at the same time. When an alarm is triggered, the module automatically records the original vibration waveform, spectrum data, and key parameters at the time of the alarm, stores the timestamp information, and provides a complete data chain for fault tracing. It supports an alarm suppression function, which automatically shields alarms during special working conditions such as equipment start-up and shutdown, with an adjustable suppression time of 0-600s.

- Data Communication and System Collaboration:The module establishes a connection with the Mark VIe controller through a dual-network port redundant communication link, and performs data interaction using the Genius Bus or Modbus TCP/IP protocol. The CPU encapsulates real-time monitoring parameters (time-domain/frequency-domain parameters, trend data), alarm information, fault logs, and equipment status data into data packets, and uploads them to the controller and upper monitoring system through the main communication network port; at the same time, it receives configuration commands (channel type, filter parameters, alarm threshold, sampling period, etc.) issued by the controller and forwards them to the DSP for execution. When the main communication network port fails, it automatically switches to the backup network port, with a switching time of ≤50ms to ensure uninterrupted data transmission. Historical vibration waveforms and spectrum data can be called remotely through upper software for offline analysis and fault diagnosis.

- Fault Diagnosis and Self-Protection:The module has a built-in comprehensive fault diagnosis circuit that monitors the following fault types in real time: sensor faults (open circuit, short circuit, sensitivity drift), channel circuit faults (amplifier failure, abnormal filter circuit), A/D converter faults, DSP calculation faults, abnormal power supply voltage, communication interruption, etc. When a fault occurs, the CPU immediately implements protection measures: when a sensor fault occurs, the corresponding channel is automatically isolated without affecting the operation of other channels; when an internal circuit fault occurs, a fault alarm is triggered and the fault information is uploaded. At the same time, the CPU records the fault information (fault type, occurrence time, channel number), stores it in non-volatile memory (not lost when power is off), and uploads it to the controller through the communication link to facilitate quick location and handling by operation and maintenance personnel.

V. Common Fault Handling

| Fault Phenomenon | Possible Causes | Handling Measures |

|---|---|---|

| Power indicator not on, module unresponsive | 1. Both redundant power supplies are interrupted; 2. Loose or reversed power connection; 3. Fault in the internal power management circuit of the module | 1. Check the power supply switch and restore normal power supply; 2. Re-tighten the power connection and check the polarity of the positive and negative electrodes; 3. Replace the module and send the faulty module for repair |

| Abnormal measurement value of a channel (too large/too small/fluctuating) | 1. Loose, damaged, or poorly grounded sensor cable; 2. Sensor fault (sensitivity drift, aging); 3. Improper setting of channel filter parameters; 4. Fault in the module channel circuit (abnormal amplifier/filter circuit) | 1. Check and re-tighten the cable, replace the damaged cable, and ensure reliable grounding of the shielding layer; 2. Use a calibrator to test the sensor performance and replace the aging sensor in a timely manner; 3. Adjust the filter parameters (such as increasing the filtering depth) to filter interference signals; 4. Replace the module or repair the channel circuit |

| Abnormal spectrum (no characteristic frequency/frequency offset) | 1. Improper sensor installation position, failing to collect valid vibration signals; 2. Incorrect FFT parameter configuration (sampling rate/points); 3. DSP calculation fault; 4. Incorrect frequency calculation due to abnormal equipment speed | 1. Readjust the sensor installation position to ensure it is close to the vibration-sensitive point; 2. Check the sampling rate (12.8kHz) and FFT point (1024 points) configuration and reset them; 3. Restart the module, and replace it if the fault persists; 4. Test the equipment speed to ensure the speed signal is accurately transmitted to the module |

| Communication interruption, module unable to interact with the controller | 1. Loose or damaged communication cable; 2. Incorrect configuration of communication protocol or parameters (IP address, port number); 3. Ethernet port fault; 4. Controller communication interface fault | 1. Re-tighten the communication cable and replace the damaged cable; 2. Check the communication protocol and parameter configuration to ensure consistency with the controller; 3. Replace the module communication interface or the module; 4. Check the controller communication interface and restart the controller if necessary |