Description

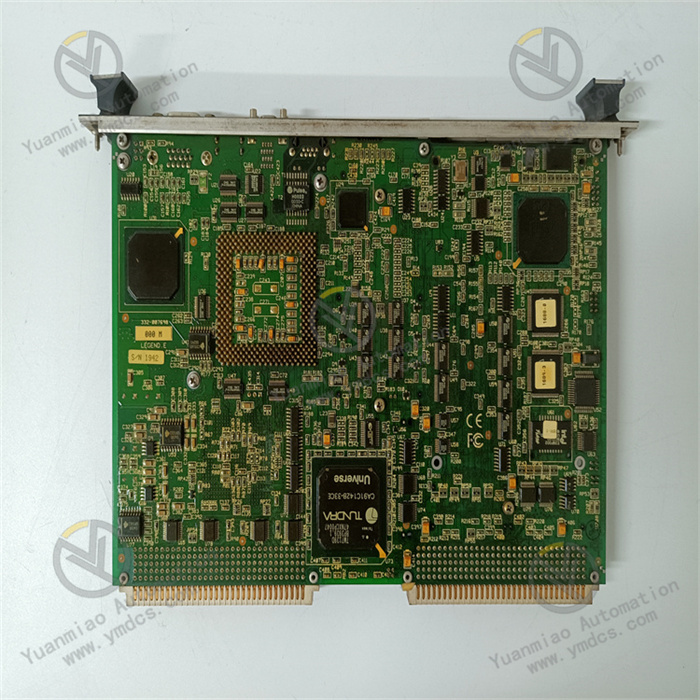

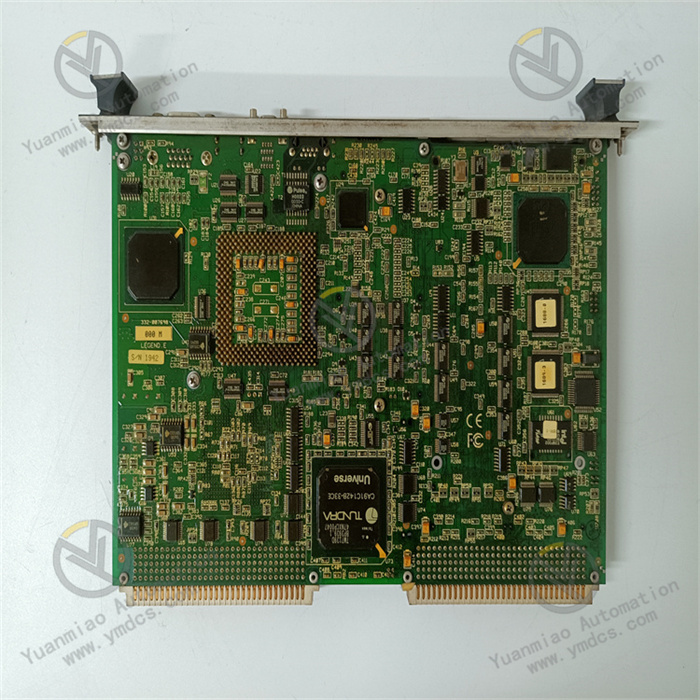

GE IS215UCVEH2AB

GE IS215UCVEH2AB is a control module that belongs to the core component system of the GE Speedtronic series control systems. It is tailor-made for the control scenarios of key power equipment such as gas turbines, steam turbines, combined-cycle generator sets, and large industrial turbomachines. It is widely used in core industrial fields with strict requirements for control accuracy, operational reliability, and real-time responsiveness, including power generation, petrochemicals, metallurgical energy, and large-scale manufacturing. Its core functions include accurately collecting signals from various on-site sensors, receiving commands from upper-level control systems, and completing signal conditioning, closed-loop regulation, logical interlocking, fault prediction, and control command output through the built-in high-performance embedded control unit and dedicated control algorithms. It enables precise control over the entire process of power equipment start-up, load adjustment, operation monitoring, and shutdown protection. Meanwhile, it is equipped with comprehensive fault diagnosis, data storage, and multi-protocol interaction capabilities, serving as a core control hub to ensure the safe, efficient, and continuous stable operation of large-scale power equipment.

This module adopts the standardized modular hardware architecture of the GE Speedtronic series, featuring excellent system compatibility and expandability. It can be directly and seamlessly integrated into mainstream control systems of the GE Mark VI, Mark VIe, and Speedtronic series. Without the need for additional adapter modules or customized drivers, it can achieve high-speed data communication with power modules, communication expansion modules, and I/O sub-modules within the system. Adhering to industrial-grade extreme environment design specifications, through multiple electromagnetic compatibility (EMC) optimizations, wide-temperature range adaptability enhancements, key circuit redundancy design, and structural reinforcement, it can stably adapt to harsh operating environments in industrial sites, such as high temperature, high humidity, heavy dust, strong vibration, strong electromagnetic radiation, and voltage fluctuations. Relying on GE's proprietary 32-bit multi-core embedded control chip and real-time operating system kernel, it achieves microsecond-level response and high-precision execution of control commands, providing solid technical support for the complex control needs of large-scale power equipment.

In-depth Adaptation to Speedtronic Systems & Seamless Efficient Integration: The module adopts the unified hardware interface specifications and communication protocol stack of the GE Speedtronic series. It can be directly inserted into standard racks of systems such as Mark VI and Mark VIe. After power-on, it automatically completes communication handshakes, parameter synchronization, and identity authentication with the system main controller, power modules, and I/O expansion modules via the high-speed backplane bus of the rack (speed ≥1Gbps), realizing "plug-and-play" rapid integration. It supports full graphical programming with mainstream configuration software such as GE Proficy iFIX, CIMPLICITY, and Intellution FIX, enabling intuitive completion of control logic writing, I/O channel mapping, PID parameter tuning, alarm threshold configuration, and redundancy strategy setting without the need for additional development of dedicated drivers. The data interaction delay with other components in the system is ≤0.3ms, ensuring real-time synchronization of control commands and monitoring data, significantly shortening the system integration and debugging cycle (reduced by more than 30% compared with traditional modules) and lowering engineering implementation costs.

Integration of Multiple Types of High-precision I/O & Comprehensive Control Coverage: It integrates 16 analog input channels, 10 analog output channels, 20 digital input channels, 12 digital output channels, and 4 pulse input channels. It can fully connect to on-site sensor signals (such as temperature, pressure, vibration, displacement, speed, and flow) and actuator control signals (such as solenoid valves, control valves, contactors, and frequency converters), realizing all-round collection of power equipment operating parameters and multi-dimensional precise control. The analog channels have an input accuracy of ±0.03%FS and an output accuracy of ±0.05%FS, which can accurately capture subtle parameter fluctuations; the digital channels support adaptive switching between dry/wet contacts without hardware jumper adjustment; the pulse channels support wide-frequency range (0~20kHz) signal input and can be directly connected to speed sensors to achieve high-precision speed measurement. All channels have independent calibration functions, allowing single-point calibration without overall shutdown, improving system maintenance convenience.

Triple-core Parallel Control Operation & Accurate Efficient Response: Equipped with a GE proprietary 32-bit triple-core embedded control processor with a main frequency of 800MHz, it adopts a triple-core parallel architecture of "signal processing-operation control-communication management". Each core operates independently with real-time data sharing, and the operation cycle is ≤0.3ms, enabling rapid processing of multi-channel concurrent signals and execution of complex control logic. The analog input response time is ≤0.5ms, the digital input response time is ≤0.3ms, and the output command delay is ≤0.8ms, which can timely capture minor changes in equipment operating status and output accurate control commands. It has strong adaptability to scenarios with extremely high real-time requirements, such as gas turbine speed regulation (control accuracy ±0.1rpm) and steam pressure closed-loop control (accuracy ±0.01MPa). It supports various complex algorithms including PID regulation, fuzzy control, adaptive control, and predictive control, which can automatically optimize control parameters according to equipment operating conditions to meet high-precision control needs under different loads and working conditions.

1:1 Hot Redundancy Configuration & Safe Reliable Operation: It supports 1:1 dual-module hot redundancy configuration. The main and standby modules achieve real-time synchronization of input signals, operation logic, output status, and alarm information via a dedicated high-speed synchronization bus (synchronization speed ≤1μs). During operation, they continuously perform mutual health checks, data verification, and clock synchronization. When the main module encounters faults such as processor failure, I/O channel abnormality, communication interruption, or power fluctuation, the standby module can automatically switch to take over the control task without disturbance within ≤2ms. During the switching process, control commands are not interrupted, output parameters are not fluctuated, and equipment operation is not impacted, ensuring continuous and stable operation of power equipment. The module has built-in fault diagnosis and fault-tolerance mechanisms, which can perform real-time monitoring of the core processor, memory, I/O channels, communication interfaces, and power circuits. When a fault is detected, it immediately triggers a local alarm (LED indicator), uploads the fault code, and automatically initiates redundancy switching. The system's Mean Time Between Failures (MTBF) is ≥100,000 hours.

Five-level Interlock Protection & Strict Safety Shielding: It is equipped with five-level alarm (prompt, attention, warning, severe, critical) and interlock protection functions. Multiple fault alarm thresholds and interlock logics (such as over-temperature, over-pressure, over-speed, excessive vibration, low oil pressure, and low water level) can be preset according to the operating procedures of power equipment. When the monitored parameter reaches the prompt threshold, only prompt information is uploaded to the upper-level system; when it reaches the attention threshold, the local green indicator flashes; when it reaches the warning threshold, the local yellow warning indicator is lit and an audible-visual alarm is triggered in the upper-level system; when it reaches the severe threshold, a load reduction control command is output and the alarm is intensified; when it reaches the critical threshold, interlock commands such as emergency shutdown, fuel cutoff, and main valve closure are immediately output, while the fault status is locked, fault data is recorded, and detailed alarm information is uploaded to prevent fault expansion from the source. It supports the storage and traceability of 300,000 pieces of historical alarm data, recording the alarm time, parameter value, fault type, handling result, and operation log, providing a reliable basis for fault troubleshooting and root cause analysis. The alarm logic supports 0~50s delay anti-shake configuration, which can effectively filter out false alarms caused by transient interference.

Multi-protocol & Multi-interface Communication & Flexible Data Interaction: Equipped with 2 RS485, 2 Ethernet, and 1 CANopen communication interfaces, it supports mainstream industrial communication protocols such as Modbus RTU/ASCII, GE Proficy, EtherNet/IP, Modbus TCP, and CANopen. It can achieve seamless data interaction with upper-level monitoring systems, HMI (Human-Machine Interface), SCADA (Supervisory Control and Data Acquisition) systems, PLCs (Programmable Logic Controllers), and data servers. Remote monitoring and operation & maintenance can be realized via the Ethernet interface. Operation and maintenance personnel can complete module program download, parameter modification, fault diagnosis, data backup, and firmware upgrade in the central control room without on-site operations, improving operation and maintenance efficiency by more than 30%. It supports multi-module networking communication, enabling the construction of a Distributed Control System (DCS) to realize collaborative control and centralized management of multiple power equipment in large industrial sites, adapting to the control needs of complex production processes. The communication process is equipped with data verification (CRC32), retransmission mechanism, and fault-tolerance processing, ensuring the reliability of data transmission (transmission bit error rate ≤10⁻⁹).

Four-layer Anti-interference Isolation Design & Adaptation to Harsh Environments: It adopts a four-layer electrical isolation design of "input-output", "input-power", "inter-channel", and "communication-power", with a maximum isolation voltage of 3500VAC/1min, effectively blocking the impact of on-site ground loops, power fluctuations, equipment electromagnetic radiation, and communication interference on the module. It has built-in high-performance EMC filter circuits, surge suppression components, electrostatic protection circuits, and RF interference shielding layers, which can withstand ±15kV electrostatic discharge shocks, ±4kV surge interference, and ±2kV pulse burst interference. It has passed the IEC 61000-4-2/3/4/5/6 series of anti-electromagnetic interference tests and can still operate stably in strong interference environments such as high-voltage frequency converters, high-power motors, and high-frequency heating equipment, with RF interference suppression ≥65dB. The sensor input and output interfaces adopt a dedicated shielding design, and when used with dedicated shielded cables, the anti-interference performance can be further improved to ensure the stability of signal transmission.

Industrial-grade Reinforced Structure & Strong Environmental Adaptability: It adopts industrial-grade high-reliability components (military-grade capacitors, high-temperature-resistant chips) and an integrated die-cast aluminum alloy shell design. The surface of the shell is treated with anodization, anti-corrosion coating, and sandblasting, featuring excellent heat dissipation, dust-proof, oil-proof, anti-corrosion, and anti-impact performance. The internal heat dissipation structure is optimized, equipped with high thermal conductivity heat dissipation fins and an intelligent temperature-controlled fan (auto on/off within the temperature range of 50~70℃), which can quickly dissipate the heat generated by core components, ensuring the module operates continuously and stably within the standard temperature range of -30~75℃. It has passed the IEC 60068-2-6 vibration test (5~200Hz, 6g acceleration) and IEC 60068-2-27 shock test (25g acceleration, 11ms duration), and can adapt to vibration during equipment operation and impact during transportation and installation. The module has an IP20 protection rating, equipped with a dust-proof panel, waterproof aviation connectors, and cable glands, which can effectively block the intrusion of dust, oil, and moisture in industrial sites, adapting to harsh operating environments with heavy dust, high temperature, high humidity, and high vibration.

Full-dimensional Self-diagnosis & Intelligent Operation & Maintenance & Reduced Maintenance Costs: It supports full-dimensional self-diagnosis function, which can perform real-time monitoring and fault diagnosis of power supply voltage, processor status, memory integrity, I/O channel signals, communication link connectivity, redundancy synchronization status, and heat dissipation system. When a fault is diagnosed, the fault type is intuitively displayed through the LED indicators on the front of the module (power indicator, operation indicator, alarm indicator, redundancy status indicator, channel status indicator). At the same time, detailed fault codes (such as speed sensor open circuit code E01, analog output short circuit code E08, communication fault code E15) and fault descriptions are uploaded via the communication interface. Operation and maintenance personnel can quickly locate the fault point through the fault code, shortening the fault troubleshooting time. It supports online programming, online debugging, and online calibration. Through configuration software, real-time monitoring of the module's operating status, real-time data of I/O channels, the operation process of control algorithms, and redundancy synchronization status can be realized. Program modification, parameter calibration, and fault repair can be completed without shutdown. It has built-in program and data backup functions, and backup data can be exported via the communication interface, supporting one-click program recovery after a fault to avoid program loss and reduce maintenance costs.

![]()