Description

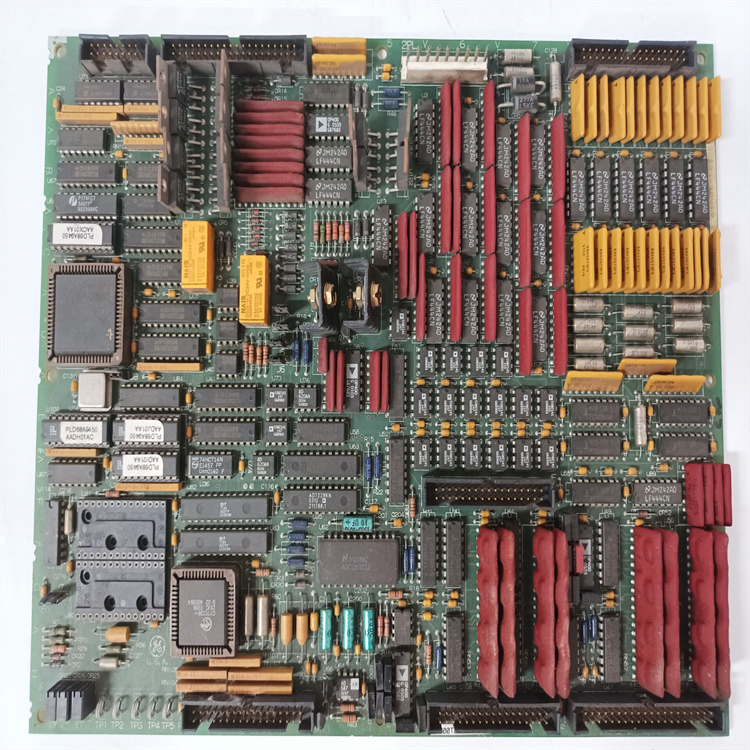

GE 531X305NTBAPG1

The GE 531X305NTBAPG1 is a high-reliability digital I/O module developed by General Electric (GE) for mid-to-high-end industrial control scenarios. It belongs to mainstream industrial control systems such as GE Mark VIe, Fanuc Series 90-30, and Centurion, with its core positioning as a "unit for accurate acquisition of multi-scenario digital signals, safe interlocking, and efficient control execution in complex industrial environments".

This module mainly serves fields with strict requirements for signal stability, system compatibility, and fault tolerance, including energy and chemical industry (e.g., valve control of refining plants, status monitoring of oil and gas transmission pumps), rail transit (signal interaction of train braking systems, status feedback of track switches), high-end manufacturing (interlocking of precision machine tools, signal switching of workstations in automated production lines), and municipal infrastructure (control of water supply pump stations, gate status management of sewage treatment plants). It undertakes the full-process core tasks of "real-time acquisition of on-site digital signals (sensor status, equipment start-stop feedback) - local logic operation and safety interlock judgment - accurate output of control commands (driving actuator actions) - active reporting of equipment faults".

With the core advantages of "high redundancy design + wide-range environmental adaptation + cross-system compatibility + intelligent fault diagnosis", the GE 531X305NTBAPG1 can not only meet the "high density and low latency" requirements of digital I/O modules for newly-built industrial control systems but also seamlessly replace traditional relay components or low-reliability I/O modules in old systems. It effectively solves the four major pain points in industrial control: "strong interference in signal transmission", "module instability in extreme environments", "poor compatibility in system upgrades", and "low efficiency in fault troubleshooting". Through enhanced electromagnetic shielding, selection of wide-temperature components, and standardized interface design, it achieves a signal acquisition response time of ≤ 0.8ms and an output command execution delay of ≤ 4ms, ensuring the continuous and stable operation of industrial systems and reducing production interruption losses caused by module failures (a single interruption can result in losses of up to several hundred thousand yuan).

- Dual Isolation and Enhanced Anti-Interference: Input/output channels all adopt 3000Vrms dual electrical isolation, combined with nano-level three-proof paint (waterproof, dustproof, anti-corrosive) coating on the circuit board. In coastal chemical workshops with high humidity and high salt spray, and metallurgical plants with strong electromagnetic interference, the annual failure rate of the module can be controlled within 0.1%. Meanwhile, the power module is equipped with a three-stage EMC filter circuit (common mode rejection ratio ≥ 90dB), and when installed next to high-power frequency converters above 300kW, the input signal misjudgment rate is ≤ 0.0005%.

Redundant Configuration of Key Components: Built-in dual-channel power supply interfaces (supporting automatic main-standby switching, switching time ≤ 1ms); when one power supply fails, the other can take over seamlessly to avoid module shutdown due to power interruption. The output relays adopt dual-coil design; when a single coil fails, the backup coil can be activated temporarily to ensure the continuous operation of the core control circuit.

- Adaptive Adjustment of Input and Output: Digital inputs support software-adaptive switching between dry contacts and wet contacts, without on-site adjustment of hardware jumpers, adapting to different types of sensors (e.g., dry-contact limit switches, wet-contact proximity switches). The output channels are compatible with AC/DC loads, and the output mode (normally open/normally closed) can be switched via software settings, without the need for additional module replacement or relays.

Local Intelligent Logic Operation: Relying on a 32-bit high-performance microprocessor, it supports complex logic operations such as 12-channel input interlocking, pulse counting, and delay triggering. It can complete "multi-condition combined control" locally (e.g., "high liquid level alarm + high pressure alarm" interlocking to close the feed valve), without relying on the computing power of the upper computer. This reduces system communication load, with a total control command delay of ≤ 12ms, meeting the real-time requirements of high-speed production lines and equipment safety interlocking.

- Full-Scenario System Adaptation: Perfectly compatible with GE-series control systems such as GE Mark VIe, Fanuc 90-30, and Centurion, and supports programming software such as GE Proficy Machine Edition and Fanuc Ladder Master. It can directly call the module's built-in function blocks (DI acquisition block, DO output block, interlocking logic block), shortening the programming cycle by 60% compared with traditional solutions. It is also compatible with third-party systems such as Siemens S7-1200/1500 and Rockwell ControlLogix, realizing cross-brand interconnection via PROFIBUS DP or Modbus RTU bus, and solving compatibility problems in the upgrading of old systems.

Seamless Replacement and Rapid Debugging: Its dimensions and installation interfaces are compatible with GE's old digital modules (e.g., 531X302, 531X304 series), which can directly replace old modules while retaining the original wiring and system programs, reducing the upgrade cost by 50%. Equipped with a USB Type-C debugging interface and visual configuration software, it supports one-click import/export of parameters, online modification of logical programs, and automatic analysis of fault logs. The module debugging time is shortened from an average of 4 hours to 30 minutes.

- Comprehensive Status Monitoring: 38 high-brightness status indicators (24 inputs + 12 outputs + 1 power + 1 bus) are installed on the front panel. On-site operation and maintenance personnel can quickly judge the module's operating status through the color and flashing state of the indicators—for example, "an input light flashes but the sensor has no action" indicates line interference; "the output light is steady on but the load does not work" indicates a relay fault. At the same time, it supports real-time viewing of module temperature, power supply voltage, bus load rate and other operating parameters through the upper computer, realizing preventive maintenance.

Efficient Fault Location and Handling: Built-in fault log storage function, which can record the latest 200 fault information (including fault type, occurrence time, fault code, and recovery measures), and supports log export via debugging interface or bus. For common faults (e.g., input disconnection, output short circuit), the module will automatically trigger protection mechanisms (e.g., cutting off the faulty output channel) and report the specific fault location and solution suggestions. The fault location time is shortened from an average of 1.5 hours to 15 minutes, greatly reducing production interruption time.

![]()