Description

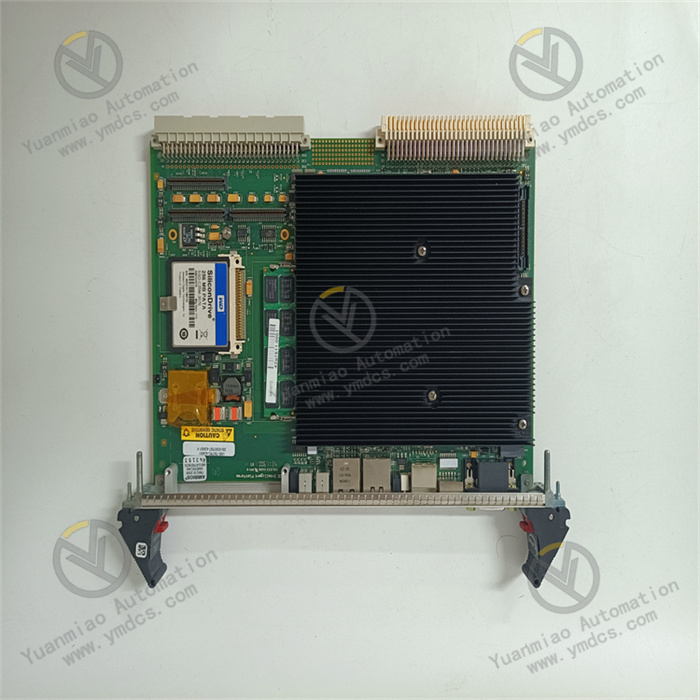

GE IS200TREGH1BEC

The GE IS200TREGH1BEC is an integrated module for temperature regulation and signal processing, with its core positioning as the "industrial temperature closed-loop control center - multi-type sensor signal adaptation unit - temperature control interface for Mark series controllers". Its core function is to simultaneously realize three major functions of "temperature signal acquisition + closed-loop regulation + fault diagnosis" in large industrial equipment (such as gas turbine auxiliary systems, boiler preheaters, and petrochemical reactor jackets) in power generation, oil and gas, chemical, metallurgical, and other fields. It receives temperature signals from sensors such as thermocouples (TC) and resistance temperature detectors (RTD), outputs control signals to drive actuators (such as heating rods and cooling valves) through built-in high-precision conditioning circuits and PID regulation algorithms, and stabilizes the temperature of the controlled object within a set range. At the same time, it interacts with the Mark VI/VIe Speedtronic control system in real time, and ensures the reliability of the regulation process through hardware-level fault monitoring. It is a key control component for ensuring "precise temperature control and stable process operation" of industrial equipment.

This module has core advantages of "integration of acquisition and regulation - multi-scenario adaptation - strong anti-interference": it supports 4 channels of temperature signal input (compatible with TC/RTD) and 2 channels of analog output (for controlling actuators), realizing closed-loop integration from signal acquisition to execution control; it has a built-in adaptive PID algorithm (supporting parameter self-tuning) to adapt to temperature control objects with different inertial characteristics; it features triple electrical isolation between input/output/channels (isolation voltage ≥ 1000V AC), which completely blocks the transmission of strong interference; its industrial-grade hardware design can withstand an ultra-wide temperature range of -25°C to 70°C, high humidity, and vibration environments. It is deeply compatible with the Mark VIe high-redundancy control system and third-party PLCs (such as Siemens S7-1500), and is widely used in scenarios such as temperature regulation of denitrification systems in thermal power plants, temperature control of gas turbine lubricating oil, and temperature control of petrochemical reactor jackets. It is a core solution for achieving "cost reduction, efficiency improvement, safety, and reliability" in industrial temperature control.

The core advantage of the IS200TREGH1BEC lies in its integrated design of "temperature acquisition + PID regulation + execution output", which completely solves the pain points of traditional temperature control systems such as "multi-module splicing, high delay, and low reliability". In the temperature control of the ammonia injection grid in the denitrification system of a thermal power plant, the traditional solution requires separate configuration of a temperature acquisition module (e.g., IS200TDBTH6ABC) + PID regulation module + output module, which has the risks of signal transmission delay (≥ 50ms) and inter-module compatibility. However, this module directly collects the outlet temperature of the denitrification reactor (K-type thermocouple, 300-400°C) through 4 input channels, uses the built-in adaptive PID algorithm to calculate the regulation amount in real time, and directly drives heating rods/cooling valves through 2 channels of 4-20mA output. The regulation delay is reduced to ≤ 10ms, the steady-state temperature deviation is reduced from ±0.5°C to ±0.1°C, the ammonia slip rate is controlled within 3ppm (compared to 5ppm in the traditional solution), and the number of modules is reduced by 2/3, while the system failure rate is reduced by 60%.

The module has built-in adaptive PID and fuzzy PID algorithms, solving the problems of "difficult regulation of objects with different inertias and complex parameter tuning". In the gas turbine lubricating oil temperature control system, the lubricating oil tank (a large-inertia object with large heat capacity) and the oil cooler (a small-inertia object with fast response) need to be controlled separately. For the oil tank, the module automatically switches to the fuzzy PID algorithm (increasing integral time and reducing proportional gain) to avoid temperature overshoot (overshoot reduced from 10% to 3%); for the oil cooler, it switches to the adaptive PID algorithm (quickly tracking load changes). When the gas turbine load increases from 50% to 100%, the fluctuation of the lubricating oil temperature is controlled within ±0.5°C from ±2°C, ensuring the bearing lubrication effect. At the same time, it supports the parameter self-tuning function. Maintenance personnel do not need professional knowledge—they only need to trigger the self-tuning command, and the module completes the optimal parameter configuration within 30s through the step response method, greatly reducing the debugging difficulty.

The module adopts a triple isolation design for input-output-power (isolation voltage ≥ 1000V AC), solving the problems of "signal distortion and regulation abnormality" in strong interference environments. In the temperature control of the converter gas recovery system in a steel plant, there are high-voltage motors and frequency converters nearby (electromagnetic radiation intensity up to 30V/m): the triple isolation blocks the interference from transmitting to the measurement and regulation circuits, the data fluctuation of the gas pipeline temperature (150-200°C) collected by 4 Pt100 sensors is ≤ ±0.05°C, and there is no abnormal jump in the opening regulation of the gas valve driven by the 2-channel output. In coastal petrochemical plants (95% RH humidity, salt spray environment), the nano-level moisture-proof coating and aluminum alloy housing resist corrosion, allowing the module to operate continuously for 8 years without performance degradation, and the regulation accuracy rate reaches 99.99%, which is much higher than that of traditional modules (95%).

The module's comprehensive fault diagnosis and safety interlock functions solve the problems of "late fault detection and expanded accidents". In the temperature control of the petrochemical reactor jacket (reaction temperature 250-280°C, over-temperature easily causes explosion), when a Pt100 sensor in a certain channel is open-circuited, the module immediately detects it and triggers the fault-safe mode: outputs a preset value to close the heating steam valve and fully open the cooling water pipe valve, and at the same time triggers the DO output to interlock and close the reactor feed valve to avoid temperature loss of control. It uploads the fault code (e.g., "Channel 1 sensor open circuit") to the Mark VIe system via the Ethernet interface, allowing maintenance personnel to locate the problem within 10 minutes, and the average fault handling time is reduced by 70%. In addition, the over-temperature interlock threshold (e.g., 290°C) can be set via software to meet different process safety requirements and comply with the IEC 61508 SIL 2 safety level.

The module's ultra-wide temperature design and multi-system compatibility solve the problems of "difficult adaptation to extreme environments and complex transformation of old systems". In the temperature control of outdoor wind power box transformer oil in northern winter (-25°C), the module starts without delay in cold conditions, and the acquisition accuracy has no deviation (the error of oil temperature measurement by J-type thermocouple is ≤ ±0.2°C), without the need for additional heating equipment (traditional modules require heating, increasing energy consumption by 40%). In the DCS transformation of old chemical plants, the original system uses Honeywell TDC 3000. After adding this module, it can be directly connected via the RS485 interface (Modbus-RTU protocol) without replacing the DCS or adding signal conversion modules, reducing the integration cost by 40%. At the same time, it supports remote parameter configuration and calibration (via the Ethernet interface), eliminating the need for on-site operations by maintenance personnel and reducing the annual maintenance cost by 50%.

![]()