Description

GE IS200SPIDG1ABA

I. Product Overview

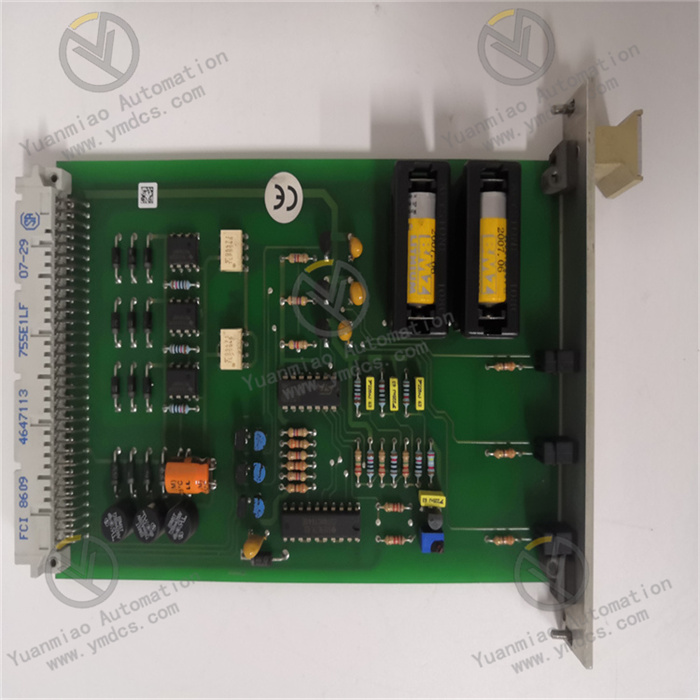

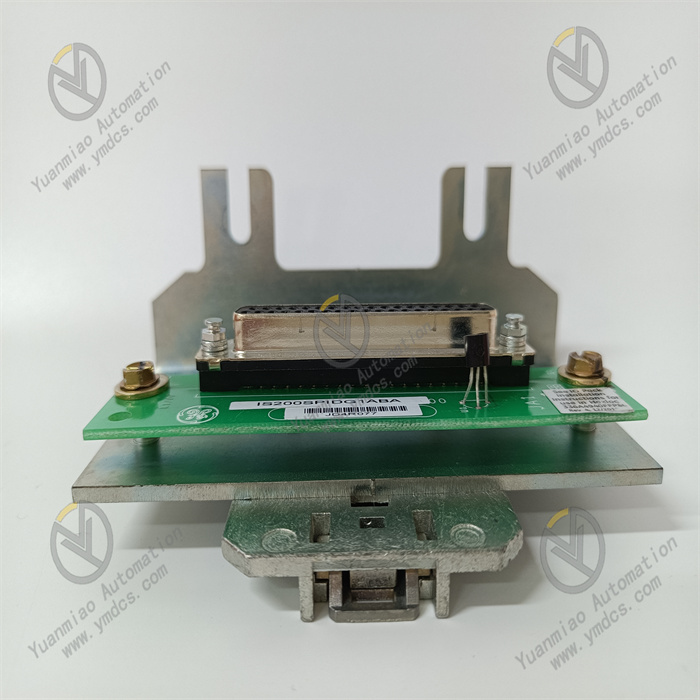

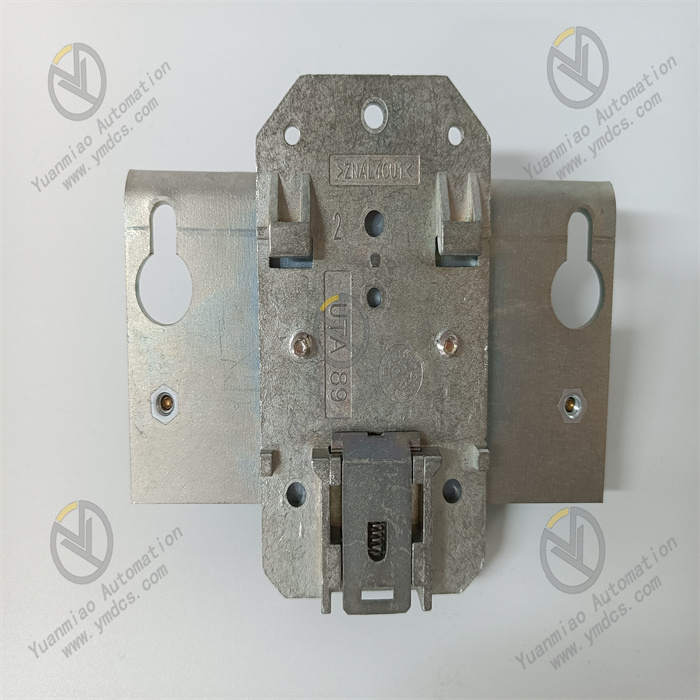

IS200SPIDG1ABA adopts a printed circuit board (PCB) design, with an overall square shape and dimensions of 13.39 inches × 8.5 inches × 2.17 inches. This design not only ensures its structural compactness but also meets the space layout requirements of different equipment. The module weighs only 2.2 pounds, facilitating easy installation and transportation, and reducing additional load requirements on the installation environment. Its shell is made of high-strength materials, featuring good impact and vibration resistance, which can effectively protect internal precision circuits and ensure stable operation in complex industrial environments.

This module is mainly used to connect external I/O devices and is one of the core components for building efficient automated control systems. It can accurately introduce signals from external devices into the system and transmit control commands from the system to external devices, realizing two-way interaction between the system and the external environment, and providing strong support for the stable and accurate operation of various industrial equipment.

II. Performance Parameters

Power supply voltage: It is powered by a 24VDC power supply. This common DC voltage specification is highly compatible with a large number of DC power supply systems in industrial sites, facilitating user access without the need for additional complex power conversion equipment, thus reducing system integration costs and difficulties.

Power consumption: In normal working conditions, the module's power consumption is only 10 watts, demonstrating excellent energy-saving characteristics. Low power consumption not only helps reduce operating costs and energy waste but also effectively reduces heat generation during the module's operation, prolonging the module's service life and improving system stability.

(2) Communication Characteristics

Transmission method: Digital I/O bus lines are transmitted through balanced differential twisted pairs. This transmission method has excellent anti-interference ability, enabling stable signal transmission in complex electromagnetic environments, effectively reducing the bit error rate during signal transmission, ensuring the accuracy and integrity of data, and providing reliable guarantee for the precise operation of industrial control systems.

Transmission method: Digital I/O bus lines are transmitted through balanced differential twisted pairs. This transmission method has excellent anti-interference ability, enabling stable signal transmission in complex electromagnetic environments, effectively reducing the bit error rate during signal transmission, ensuring the accuracy and integrity of data, and providing reliable guarantee for the precise operation of industrial control systems.

Connector: Equipped with a 40-pin locked IS200SPIDG1ABA type connector, which has good electrical connection performance and mechanical stability. The tight locking mechanism can prevent the connector from loosening in harsh environments such as vibration and impact, ensuring the continuity of signal transmission, and at the same time facilitating the installation and disassembly of the module, improving maintenance efficiency.

Cable: Matched with a 40-core twisted-pair flat cable, this cable has a compact structure and good flexibility, facilitating wiring. Its twisted-pair structure further enhances anti-interference ability, ensuring that signals are not affected by external interference during transmission, and achieving efficient and stable data transmission.

Communication rate: Supports high-speed I/O, with an extremely fast data transmission rate of up to [specific high-speed transmission rate], which can quickly respond to system commands and collect and transmit external device signals in real-time. In industrial automation scenarios with high real-time requirements, such as equipment status monitoring and control in high-speed production lines, this module can quickly transmit equipment status information to the control system, enabling the control system to make timely decisions and ensuring the smooth progress of the production process.

(3) Reliability Characteristics

Fail-safe operation: The bus receiver has a fail-safe operation function. When an abnormality such as an interruption of the bus cable occurs, it can automatically reset all data and data direction registers, preventing data errors or system out of control caused by communication interruption. This mechanism ensures that even if the communication link fails, the module can maintain a certain safe state, providing an important guarantee for system reliability.

Fail-safe operation: The bus receiver has a fail-safe operation function. When an abnormality such as an interruption of the bus cable occurs, it can automatically reset all data and data direction registers, preventing data errors or system out of control caused by communication interruption. This mechanism ensures that even if the communication link fails, the module can maintain a certain safe state, providing an important guarantee for system reliability.

Self-diagnostic function: It has a complete self-diagnostic function, which can monitor key parameters such as the module's power supply status, communication status, and connection status of each port in real-time. Once an abnormality is detected, such as abnormal power supply voltage, communication line failure, port short circuit or open circuit, the module will immediately generate a detailed fault code and upload the fault information to the control system through the communication interface. At the same time, the fault indicator on the module will light up accordingly, facilitating maintenance personnel to quickly locate the fault point, shorten the fault troubleshooting and repair time, and improve system availability.

Environmental adaptability

Operating temperature range: It can work stably in extreme temperature environments ranging from -40°C to +85°C. Whether in cold outdoor industrial facilities, such as wind farms in northern winter, or high-temperature industrial production workshops, such as steel smelters, the module can operate normally, ensuring the continuity and accuracy of data collection and transmission without being affected by changes in ambient temperature.

Operating temperature range: It can work stably in extreme temperature environments ranging from -40°C to +85°C. Whether in cold outdoor industrial facilities, such as wind farms in northern winter, or high-temperature industrial production workshops, such as steel smelters, the module can operate normally, ensuring the continuity and accuracy of data collection and transmission without being affected by changes in ambient temperature.

Humidity adaptability: Adapts to a humidity environment of 5% to 95% (non-condensing). In humid industrial environments, such as paper mills and printing and dyeing factories, the module will not experience problems such as reduced electrical performance or short circuits due to humidity, ensuring reliable operation under different humidity conditions.

Vibration and impact resistance: It has undergone strict vibration and impact tests and has good vibration and impact resistance. The module can still work normally under vibration conditions with a vibration frequency of [specific frequency range] and an acceleration of [specific acceleration value], as well as under impact conditions with an impact acceleration of [specific impact acceleration value]. This enables it to maintain stable operation during transportation, installation, and when near industrial equipment with large vibrations, ensuring system reliability.

Electromagnetic compatibility: Complies with international electromagnetic compatibility standards, with excellent anti-electromagnetic interference ability and low electromagnetic radiation characteristics. In complex electromagnetic environments with a large number of high-voltage equipment and high-frequency interference sources in industrial sites, the module will not be affected by external electromagnetic interference, and its own low electromagnetic radiation will not interfere with surrounding equipment, ensuring the stable operation of the entire industrial control system.

III. Application Scenarios

Power plant excitation system: In power plants, IS200SPIDG1ABA is used to connect the excitation control system with various external monitoring and control equipment. It can collect the operating parameters of the generator in real-time, such as voltage, current, power and other signals, and quickly transmit these data to other modules in the excitation control cabinet, realizing precise control and monitoring of the generator excitation system. When the generator load changes, the module can quickly transmit the signal to the control system, enabling the system to adjust the excitation current in a timely manner, ensuring the stability of the generator's output voltage and reliable power supply.

Substation automation system: In substations, this module can connect various intelligent terminal devices, such as circuit breaker status monitoring sensors and disconnector position detection devices. By collecting the status signals of these devices in real-time and transmitting them to the substation automation control system, remote monitoring and automatic operation of substation equipment are realized. For example, when an abnormal opening and closing signal of a circuit breaker in a certain line is detected, the module can quickly upload the information to the control system, which can issue an alarm in time and take corresponding control measures to ensure the safe and stable operation of the substation.

(2) Industrial Automation

Manufacturing production lines: In automated production lines such as automobile manufacturing and electronic equipment manufacturing, IS200SPIDG1ABA plays a key role. It can connect various equipment on the production line, such as robot controllers, conveyor drive devices, and material sensors. By collecting the operating status signals of the equipment in real-time, such as the working mode of the robot, the running speed of the conveyor belt, and the position information of materials, and transmitting these data to the production line control system, precise control and coordination of the entire production process are realized. When a device fails, the module can quickly detect the fault signal and upload it to the control system, which can pause the relevant processes in time to avoid producing unqualified products, improving production efficiency and product quality.

Manufacturing production lines: In automated production lines such as automobile manufacturing and electronic equipment manufacturing, IS200SPIDG1ABA plays a key role. It can connect various equipment on the production line, such as robot controllers, conveyor drive devices, and material sensors. By collecting the operating status signals of the equipment in real-time, such as the working mode of the robot, the running speed of the conveyor belt, and the position information of materials, and transmitting these data to the production line control system, precise control and coordination of the entire production process are realized. When a device fails, the module can quickly detect the fault signal and upload it to the control system, which can pause the relevant processes in time to avoid producing unqualified products, improving production efficiency and product quality.

Industrial robot control: In industrial robot application scenarios, this module is used to connect the robot's controller with external sensors and actuators. It can collect sensor signals from the robot's surrounding environment in real-time, such as image data from visual sensors and force information from force sensors, and transmit these data to the robot controller, enabling the robot to make accurate action decisions according to environmental changes. At the same time, the module can also transmit control commands from the controller to the robot's actuators, realizing precise control of the robot's movement, ensuring that the robot can efficiently and accurately complete various tasks in industrial production, such as material handling, welding, and assembly.

(3) Process Control

Petrochemical industry: In the petrochemical production process, there are a large number of pumps, valves, compressors and other equipment. IS200SPIDG1ABA can be used to connect the status monitoring sensors and control systems of these equipment. By collecting the operating status signals of the equipment in real-time, such as the running/stopping status of pumps, the opening/closing status of valves, and the fault alarm signals of equipment, and uploading these signals to the Distributed Control System (DCS), operators can grasp the operation of the equipment in real-time. When the equipment is abnormal, the DCS system can issue an alarm in time and automatically take corresponding control measures, such as closing relevant valves and stopping the operation of upstream and downstream equipment, to prevent the expansion of accidents and ensure production safety.

Petrochemical industry: In the petrochemical production process, there are a large number of pumps, valves, compressors and other equipment. IS200SPIDG1ABA can be used to connect the status monitoring sensors and control systems of these equipment. By collecting the operating status signals of the equipment in real-time, such as the running/stopping status of pumps, the opening/closing status of valves, and the fault alarm signals of equipment, and uploading these signals to the Distributed Control System (DCS), operators can grasp the operation of the equipment in real-time. When the equipment is abnormal, the DCS system can issue an alarm in time and automatically take corresponding control measures, such as closing relevant valves and stopping the operation of upstream and downstream equipment, to prevent the expansion of accidents and ensure production safety.

Pharmaceutical industry: In the pharmaceutical production process, there are extremely high requirements for precise control of the production environment and equipment operation. IS200SPIDG1ABA can be used to connect various sensors and controllers of pharmaceutical equipment, such as temperature sensors, pressure sensors, and flow controllers. By collecting various parameter signals in the production process in real-time and transmitting them to the pharmaceutical process control system, precise monitoring and adjustment of the production process are realized. For example, in the process of drug synthesis reaction, the module can collect real-time temperature, pressure and other signals in the reactor and transmit these data to the control system. The control system automatically adjusts the operation status of heating, cooling, stirring and other equipment according to the preset process parameters, ensuring the stability and consistency of the drug production process and guaranteeing drug quality.