Description

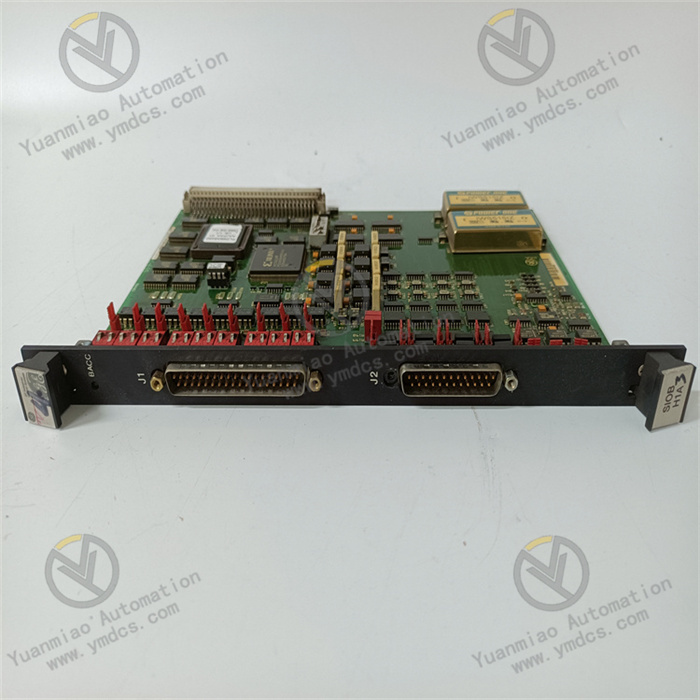

GE IS200PMCIH1ABA

I. Product Overview

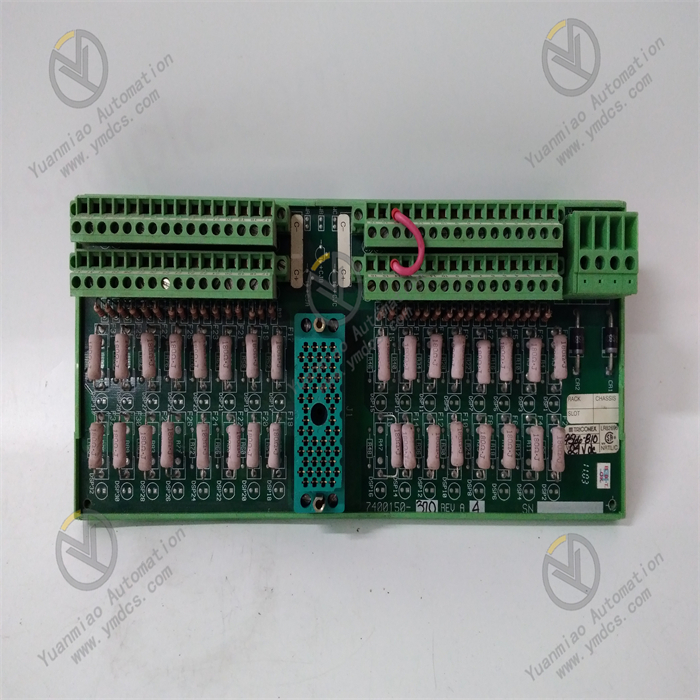

IS200PMCIH1ABA adopts an advanced printed circuit board (PCB) design with a compact and reasonable overall structure. Its external dimensions are carefully planned, enabling it to fit well into various industrial control cabinets, realize efficient installation in limited space, and meet the needs of different equipment layouts. The weight of the module is optimized, facilitating installation and transportation, and reducing the load requirements on the installation environment.

The shell is made of high-strength, corrosion-resistant high-quality industrial materials, with excellent impact and vibration resistance. This allows the module to work reliably in complex industrial environments with much dust and frequent vibrations, effectively protecting the internal precision electronic components from external factors and ensuring the long-term stable operation of the module.

IS200PMCIH1ABA mainly undertakes the important responsibilities of data processing and signal conversion, and is one of the core components in industrial automation control systems. It can accurately process and convert various collected signals, realize efficient communication and collaborative work between different devices, and provide reliable data support for the precise control of industrial production processes.

II. Performance Parameters

Power supply voltage: It is powered by 24VDC DC power supply. This voltage specification is widely used in the industrial field, compatible with most industrial DC power supply systems, facilitating user access without additional power conversion equipment, reducing the cost and complexity of system integration.

Power consumption: In normal working condition, the power consumption of the module is low, only [specific power consumption value] watts. The low-power design not only helps save energy and reduce operating costs, but also reduces the heat generation during the operation of the module, prolongs the service life of the module, and improves the stability of the system.

(2) Processing Capacity

Data processing speed: Equipped with a high-performance processor, it has a fast data processing speed, which can quickly respond to and process signals from various sensors and equipment. For complex industrial control scenarios, such as real-time monitoring and control of high-speed production lines, it can quickly complete data analysis and processing to ensure that the control system makes decisions in a timely manner.

Data processing speed: Equipped with a high-performance processor, it has a fast data processing speed, which can quickly respond to and process signals from various sensors and equipment. For complex industrial control scenarios, such as real-time monitoring and control of high-speed production lines, it can quickly complete data analysis and processing to ensure that the control system makes decisions in a timely manner.

Signal conversion accuracy: It has a high-precision signal conversion function, which can accurately convert analog signals into digital signals, with the conversion error controlled within [specific error range]. High-precision signal conversion ensures the accuracy of data, providing a reliable basis for precise adjustment of industrial control.

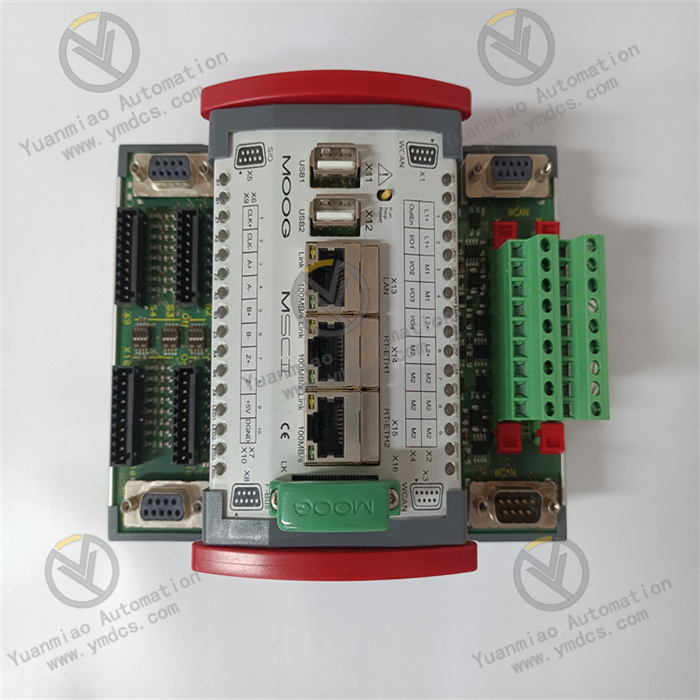

(3) Communication Characteristics

Communication interfaces: Equipped with a variety of common communication interfaces, such as Ethernet interface, RS-485 interface, etc., which can be connected with different types of equipment and control systems. The rich types of interfaces enhance the compatibility and expansibility of the module, enabling it to be flexibly applied to various industrial communication scenarios.

Communication interfaces: Equipped with a variety of common communication interfaces, such as Ethernet interface, RS-485 interface, etc., which can be connected with different types of equipment and control systems. The rich types of interfaces enhance the compatibility and expansibility of the module, enabling it to be flexibly applied to various industrial communication scenarios.

Communication rate: It supports high-speed communication. The communication rate of the Ethernet interface can reach [specific Ethernet rate], and the communication rate of the RS-485 interface can be adjusted within [specific rate range] according to actual needs. High-speed communication capability ensures the rapid transmission of data, meeting the real-time requirements of industrial control systems.

Communication protocols: It supports a variety of mainstream industrial communication protocols, such as Modbus, Profinet, etc., and can seamlessly connect with devices and systems that follow these protocols to realize efficient data interaction and sharing.

(4) Reliability Characteristics

Self-diagnostic function: It has a perfect self-diagnostic function, which can real-time monitor the power supply status, communication status, internal circuit working status of the module, etc. When abnormal situations are detected, such as power failure, communication interruption, circuit failure, etc., it will immediately send out an alarm signal, upload the fault information to the control system through the communication interface, and light up the fault indicator on the module, facilitating maintenance personnel to quickly locate and eliminate faults, and improving the availability of the system.

Self-diagnostic function: It has a perfect self-diagnostic function, which can real-time monitor the power supply status, communication status, internal circuit working status of the module, etc. When abnormal situations are detected, such as power failure, communication interruption, circuit failure, etc., it will immediately send out an alarm signal, upload the fault information to the control system through the communication interface, and light up the fault indicator on the module, facilitating maintenance personnel to quickly locate and eliminate faults, and improving the availability of the system.

Anti-interference ability: It has passed strict electromagnetic compatibility tests and has strong anti-electromagnetic interference ability. In the industrial field with a large number of electromagnetic interference sources such as high-voltage equipment and high-frequency signals, the module can work stably without being affected by external interference, ensuring the accuracy of data transmission and processing.

Environmental adaptability

Operating temperature range: It can work normally in a wide temperature range of -40°C to +70°C, and can adapt to different temperature conditions such as cold outdoor environments and high-temperature industrial workshops, ensuring the stable operation of the module under various extreme temperatures.

Operating temperature range: It can work normally in a wide temperature range of -40°C to +70°C, and can adapt to different temperature conditions such as cold outdoor environments and high-temperature industrial workshops, ensuring the stable operation of the module under various extreme temperatures.

Humidity adaptability: It can work reliably in an environment with a relative humidity of 5% to 95% (non-condensing). In humid industrial environments, such as paper mills and food processing plants, its performance will not be affected by humidity issues.

Vibration and impact resistance: It has good vibration and impact resistance, and can withstand vibrations with a vibration frequency of [specific frequency range] and an acceleration of [specific acceleration value], as well as impacts with an impact acceleration of [specific impact acceleration value], ensuring that the module will not be damaged by vibration or impact during transportation, installation and operation.

III. Application Scenarios

In the control of generator sets in the power industry, IS200PMCIH1ABA plays an important role. It can collect key operating parameters of the generator set, such as speed, temperature, pressure, etc., and after processing and conversion, transmit the data to the generator set control system. The control system adjusts and controls the generator set according to these data to ensure the stable operation of the generator set and improve power generation efficiency and safety. For example, when it is detected that the temperature of the generator set is too high, the module can quickly transmit the signal to the control system, and the control system takes cooling measures in time to avoid equipment damage.

(2) Petroleum and Chemical Industry

In the petroleum and chemical production process, there are a large number of equipment such as reaction kettles, pipelines, pumps, etc., and it is necessary to monitor and control their pressure, temperature, flow and other parameters in real-time. IS200PMCIH1ABA can be connected to various sensors to collect these parameter signals, and after processing and conversion, transmit them to DCS (Distributed Control System). DCS adjusts the production process according to the received data, such as controlling the opening of valves, adjusting the speed of pumps, etc., to ensure the stability and safety of the production process. In the chemical reaction process, the module's precise signal conversion and fast data processing capabilities can ensure the precise control of reaction conditions and improve product quality.

In the petroleum and chemical production process, there are a large number of equipment such as reaction kettles, pipelines, pumps, etc., and it is necessary to monitor and control their pressure, temperature, flow and other parameters in real-time. IS200PMCIH1ABA can be connected to various sensors to collect these parameter signals, and after processing and conversion, transmit them to DCS (Distributed Control System). DCS adjusts the production process according to the received data, such as controlling the opening of valves, adjusting the speed of pumps, etc., to ensure the stability and safety of the production process. In the chemical reaction process, the module's precise signal conversion and fast data processing capabilities can ensure the precise control of reaction conditions and improve product quality.

(3) Manufacturing Industry

In the automated production lines of the manufacturing industry, IS200PMCIH1ABA can be used to connect robots, conveyors, processing equipment, etc., to collect the operating status signals of the equipment, such as position, speed, pressure, etc. Through the processing and analysis of these signals, the collaborative control and optimization of the production line are realized. When a certain equipment on the production line is abnormal, the module can detect it in time and upload the information to the control system, and the control system can respond quickly, such as pausing related processes, adjusting the production rhythm, etc., to avoid the production of unqualified products and improve production efficiency.

In the automated production lines of the manufacturing industry, IS200PMCIH1ABA can be used to connect robots, conveyors, processing equipment, etc., to collect the operating status signals of the equipment, such as position, speed, pressure, etc. Through the processing and analysis of these signals, the collaborative control and optimization of the production line are realized. When a certain equipment on the production line is abnormal, the module can detect it in time and upload the information to the control system, and the control system can respond quickly, such as pausing related processes, adjusting the production rhythm, etc., to avoid the production of unqualified products and improve production efficiency.

(4) Metallurgical Industry

In the steel production process of the metallurgical industry, the environment with high temperature, high pressure and much dust has extremely high requirements on the reliability of equipment. IS200PMCIH1ABA can be used to monitor parameters such as temperature, pressure and liquid level of equipment such as blast furnaces and converters, process the collected signals and transmit them to the control system. The control system controls the equipment according to these data, such as adjusting the fuel supply, controlling the cooling water volume, etc., to ensure the stable progress of steel production. The module's excellent anti-interference ability and environmental adaptability enable it to work reliably in harsh metallurgical environments, providing a strong guarantee for steel production.

In the steel production process of the metallurgical industry, the environment with high temperature, high pressure and much dust has extremely high requirements on the reliability of equipment. IS200PMCIH1ABA can be used to monitor parameters such as temperature, pressure and liquid level of equipment such as blast furnaces and converters, process the collected signals and transmit them to the control system. The control system controls the equipment according to these data, such as adjusting the fuel supply, controlling the cooling water volume, etc., to ensure the stable progress of steel production. The module's excellent anti-interference ability and environmental adaptability enable it to work reliably in harsh metallurgical environments, providing a strong guarantee for steel production.