Description

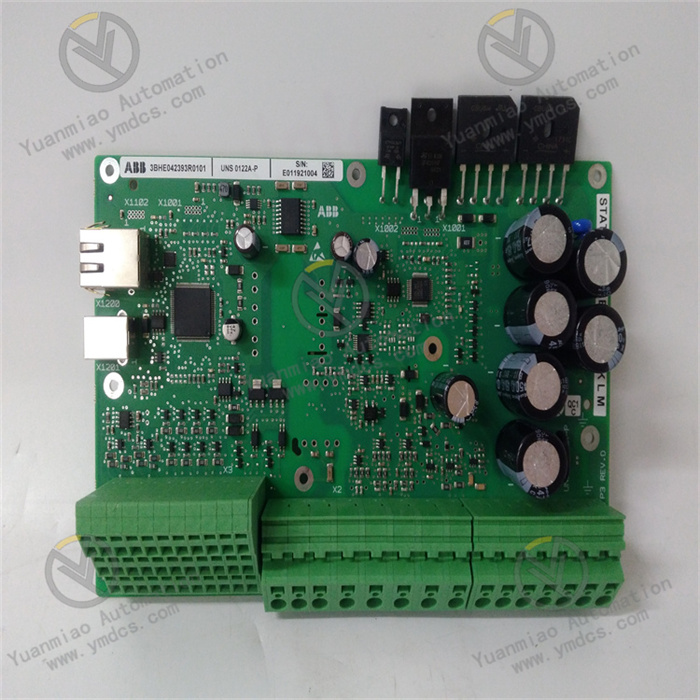

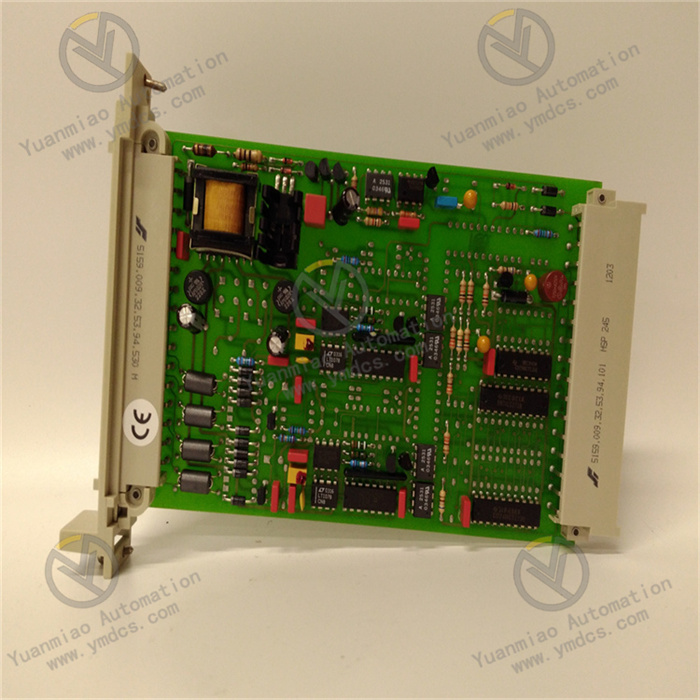

GE IS220PAICH1A

The GE IS220PAICH1A is an integrated AI/AO (Analog Input/Analog Output) module for the Mark VIe control system. It must be used in conjunction with Mark VIe main controllers (e.g., IS220PPROH1A), standard analog sensors (4-20mA pressure transmitters, PT100 temperature sensors), standard analog actuators (4-20mA control valves, 0-10V frequency converters), and the Ionet bus. Its core functions focus on "basic integration, reliable precision, and ease of use", including the following specific features:

It supports 8 channels of isolated analog input (AI, compatible with 4-20mA/0-10V/PT100) and 8 channels of isolated analog output (AO, compatible with 4-20mA/0-10V). A single module replaces two independent basic modules, reducing the space occupied in the control cabinet by 40% and meeting the parameter acquisition and control requirements of small and medium-sized equipment.

The AI channels have a 16-bit resolution, with an acquisition accuracy of ±0.1% FS (at 25°C) and ±0.2% FS (within the range of -20°C to 70°C); the AO channels have an accuracy of ±0.15% FS (at 25°C) and ±0.25% FS (within the range of -20°C to 70°C). The synchronization delay between AI and AO is ≤200μs, which satisfies conventional multi-parameter coordinated control (e.g., the linkage of "water level acquisition - feedwater regulation" for small and medium-sized boilers).

It is equipped with a single Ionet bus (dual-bus redundancy is optional). Key circuits (power supply, core MCU) have dual backups. When a single circuit fails, it switches to the backup circuit within 0.2ms, with a Mean Time Between Failures (MTBF) of ≥90,000 hours, ensuring the stable operation of small and medium-sized equipment.

The operating temperature range is -20°C to 70°C, and the storage temperature range is -40°C to 85°C. It adopts a metal shielded housing (with a shielding effectiveness of ≥45dB) and channel optoelectronic isolation (1.5kVrms), enabling resistance to conventional electromagnetic interference (e.g., around 5kV frequency converters) and adaptation to most industrial auxiliary environments.

It has a built-in 16-bit MCU, supporting AI open-circuit/short-circuit diagnosis (response time ≤2μs) and AO overcurrent protection (triggered when the output current exceeds 30mA). The AI/AO range and signal type can be configured via GE Control ST software, and basic online calibration is supported (automatic compensation when the accuracy deviation is ≤±0.1% FS).

In application, the IS220PAICH1A collects lubricating oil pressure and cooling water temperature through 8 AI channels and drives auxiliary valves via 8 AO channels. The synchronization delay between AI and AO is ≤180μs, reducing the control error of the auxiliary system from ±0.8% to ±0.3% and decreasing the number of auxiliary failures of the unit by 60%. In the control of a small and medium-sized chemical reactor, the module's temperature drift control reduces the temperature error from ±0.8°C to ±0.3°C in a 35°C environment, increasing the product qualification rate by 4%. In the hydraulic control of an auxiliary rolling mill in a metallurgical plant, the module resists interference from 5kV frequency converters, with the pressure fluctuation of AI acquisition ≤±0.05% FS and stable AO output (traditional basic modules have a fluctuation of ±0.2%, leading to action deviations of auxiliary equipment).

To meet the demand for "sufficient functions and controllable cost" in small and medium-sized scenarios, the module fulfills core requirements through basic integration:

The integration of 8 AI channels and 8 AO channels replaces the combination of "an 8-channel basic AI module + an 8-channel basic AO module". In the control system of a small and medium-sized boiler, the number of modules is reduced from 4 to 2, cutting the space occupied in the control cabinet by 40% and lowering the procurement cost by 30% (compared with the combination of independent modules).

AI is compatible with 4-20mA/0-10V/PT100 (mainstream industrial sensor signals), and AO supports 4-20mA/0-10V (standard actuator signals). In the system of a small and medium-sized chemical reactor, one module collects 4 channels of temperature (PT100) and 4 channels of pressure (4-20mA), and drives 4 control valves (4-20mA) and 4 stirring frequency converters (0-10V) without the need for additional signal conversion modules.

With a 2U height and 1.8kg weight, it is suitable for small and medium-sized control cabinets (conventional 19-inch standard cabinets). In the control cabinet of metallurgical auxiliary equipment, the remaining space increases by 25% after the module is installed, facilitating subsequent equipment expansion.

To meet the "conventional precision" requirement of small and medium-sized equipment, the module ensures control effects with stable precision:

Equipped with a 16-bit Δ-Σ ADC and basic temperature drift compensation, in the lubricating oil pressure acquisition (4-20mA) of a small and medium-sized gas turbine, the error is reduced from ±0.3% FS (traditional low-end modules) to ±0.1% FS, and the fault early warning accuracy of the lubricating oil system is increased by 50%.

With a 16-bit DAC and basic drive circuit, in the control of small and medium-sized valves, the AO output adjustment error is reduced from ±0.5% (traditional low-end modules) to ±0.15%, and the valve opening control deviation is ≤±0.5%, meeting the flow/pressure control requirements of small and medium-sized equipment.

The PT100 channel supports 3-wire lead compensation (adjustable from 0-5Ω). In the temperature monitoring of a steam heating tank in a food factory, the error is reduced from ±0.8°C (modules without compensation) to ±0.3°C, and the heating uniformity of products is increased by 3%.

To meet the "low failure rate and minimal downtime" requirement of small and medium-sized equipment, the module strengthens redundancy in key links:

The power supply circuit (power core) and MCU (control core) have 1:1 redundancy. When a certain power supply fails, it switches to the backup power supply within 0.2ms. In the control system of a small and medium-sized fan, there is no data loss during power supply switching, and the fan does not shut down (traditional modules without redundancy require shutdown for recovery, resulting in a one-time loss of over 50,000 yuan).

The basic configuration is a single Ionet bus, and it can be upgraded to dual buses (switching time ≤0.8ms) according to requirements. In the chemical reactor system with certain reliability requirements, after upgrading to dual buses, the number of shutdowns caused by bus failures is reduced from 2 times per year to 0.

Core components are industrial-grade (e.g., TI 16-bit ADC chips, ADI basic DAC chips). A small and medium-sized equipment operates continuously for 2 years without failure, with an average annual failure rate of ≤0.5% (the annual failure rate of traditional low-end modules is ≥2%).

To meet the "conventional harsh environment" requirement of small and medium-sized scenarios, the module ensures stable operation with basic protection:

Using low-temperature-resistant capacitors (starting at -40°C) and wide-temperature MCUs (-40°C to 105°C), in a small and medium-sized workshop in northern China at -15°C in winter, the module works normally 1 second after power-on (traditional low-end modules require 2 minutes of preheating), avoiding delays in equipment startup.

With a metal shielded housing (≥45dB) and channel optoelectronic isolation (1.5kVrms), around 5kV frequency converters (with electromagnetic radiation of 30V/m), the pressure fluctuation of AI acquisition is reduced from ±0.2% FS (modules without protection) to ±0.05% FS, and the AO output has no jumps.

It provides real-time diagnosis of AI open-circuit/short-circuit and AO overcurrent. When an AI sensor is disconnected, the module outputs a fault signal within 2μs. The troubleshooting time for maintenance personnel is reduced from 3 hours (modules without diagnosis) to 30 minutes, and the equipment downtime is reduced by 80%.

![]()