Description

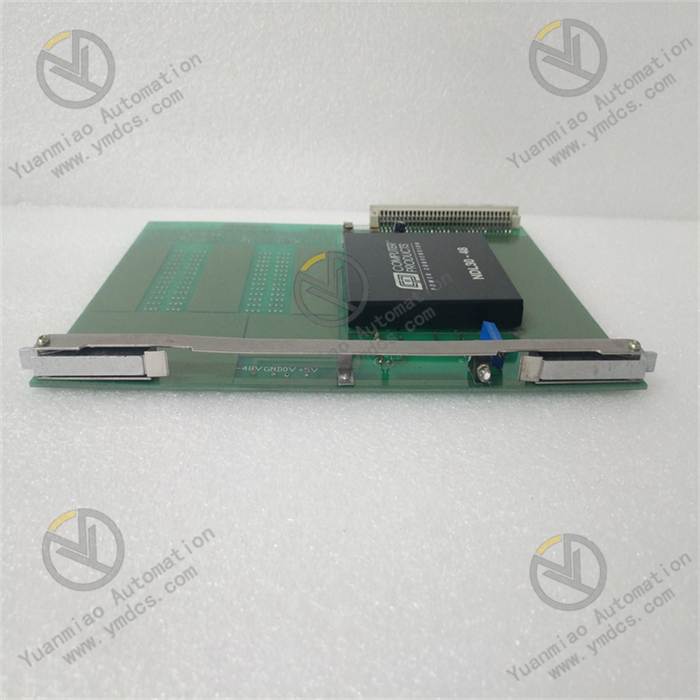

Functional Features: High-precision measurement: If it is a sensor product, it may have the ability of high-precision measurement, and can accurately sense the changes of physical quantities such as temperature, pressure, displacement, etc., and convert them into electrical signals for output, providing accurate data support for subsequent control and monitoring. High reliability: In an industrial environment, it usually needs to have high reliability and be able to operate stably under harsh working conditions, such as high temperature, high humidity, strong electromagnetic interference and other environments. High-quality materials and advanced manufacturing processes may be adopted to ensure the long-term stability and durability of the product. Strong compatibility: For the convenience of integration with other devices or systems, it may have a variety of standard interfaces and communication protocols, such as RS - 485, Modbus, Profibus, etc., and can seamlessly connect with devices from different manufacturers to achieve data transmission and sharing. Flexible configuration: It may support multiple configuration methods to meet the needs of different users. For example, parameters such as the measurement range, accuracy, and output mode can be adjusted through software or hardware settings, enabling the product to adapt to various application scenarios. Self-diagnosis function: It has the self-diagnosis ability and can monitor its own working status in real time. When a fault is detected, it can send fault information to external devices through indicator lights, alarm signals or communication interfaces, which is convenient for maintenance personnel to quickly locate and troubleshoot faults and reduce downtime. Compact shape design: Considering the limitation of installation space, it may adopt a compact shape design, which is convenient for installation in various devices or control cabinets. At the same time, standard installation methods such as rail installation or screw fixing may be used, which is convenient and quick.

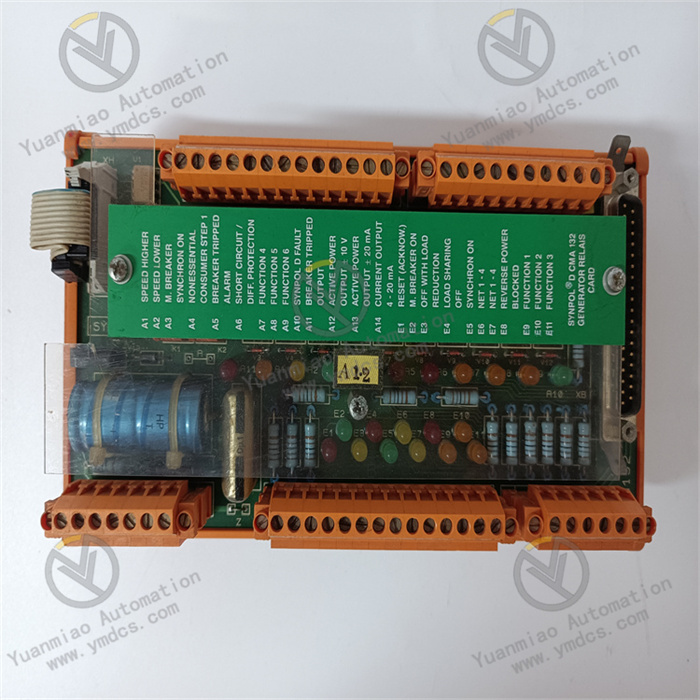

Technical Parameters Power requirements: It may be powered by a DC power supply. Common power supply voltages for industrial control modules are 24V DC, with an allowable voltage fluctuation range, such as ±10% - ±20%. Communication interface: Considering its application in industrial control, it may have common communication interfaces, such as Profibus - DP, Modbus - RTU, etc., for communication and data exchange with other devices or control systems. Input and output characteristics: If it is used in the control field, it may have a variety of input and output signal types. For example, digital input and output are used to control switch devices, and analog input and output are used to connect sensors and actuators, receiving or outputting signals such as 4 - 20mA current signals, 0 - 10V voltage signals, etc. The number of input and output channels may be multiple, and the specific quantity varies according to the model and configuration.

Common Faults and Solutions Communication Fault Fault phenomenon: The module cannot communicate normally with other devices, and cannot read or write data in the control system. Fault cause: Loose communication interface, incorrect communication parameter settings, damaged communication line, electromagnetic interference, etc. Solution: Check whether the communication interface is firmly connected and re-plug it; confirm that the communication parameter settings match those of other devices in the system; check whether the communication line is damaged, open-circuited or short-circuited, and replace it if it is damaged; check whether there are strong electromagnetic interference sources around and take measures such as shielding and filtering to reduce interference. Power Fault Fault phenomenon: The module cannot work normally, and the power indicator does not light up or the module overheats abnormally. Fault cause: Input power not connected, abnormal power voltage, fault in the internal power circuit of the module, etc. Solution: Check whether the input power is normal, measure whether the power voltage is within the working range allowed by the module, and adjust the power to meet the requirements; check whether the power wiring of the module is firmly connected; if the external power and wiring are both okay, it may be a fault in the internal power circuit of the module, and the module needs to be sent for repair or replaced. Abnormal Output Signal Fault phenomenon: The analog or digital output signal does not match the expectation, such as incorrect signal values, unstable signals or no signal output. Fault cause: Faults in the internal signal processing circuit of the module, incorrect output wiring, load problems, etc. Solution: Check whether the output wiring is correct and firmly connected; check whether the load is normal, whether there are overload, short-circuit or open-circuited conditions, and repair or replace the load; if the wiring and load are normal, it may be a fault in the internal signal processing circuit of the module, and contact professional maintenance personnel to repair or replace the module.

Application Cases: Automobile manufacturing production line: On the automobile engine assembly line, this module can be connected to various sensors (such as torque sensors, position sensors, etc.) and actuators (such as electric tightening guns, robotic arm controllers, etc.). By receiving the signals fed back by the sensors, it can monitor various parameters during the assembly process in real time, such as whether the bolt tightening torque meets the standard, whether the installation position of parts is accurate, etc., and control the actuators to complete corresponding actions according to the preset programs and logic to ensure the quality and consistency of engine assembly. In addition, in the automobile body welding production line, it can be used to control the actions of welding robots, monitor parameters such as welding current and voltage, and ensure the stable and reliable welding quality. Chemical production process control: In the control system of chemical reaction kettles, it can be connected to temperature sensors, pressure sensors, flow sensors, etc., and collect data such as the temperature, pressure, and material flow rate inside the reaction kettle in real time, and transmit these data to the controller for analysis and processing. According to the analysis results, the controller controls the operating status of devices such as feed valves, discharge valves, and agitator motors through this module to achieve precise control of the chemical reaction process, ensuring that the reaction proceeds under safe and stable conditions and improving product quality and production efficiency. At the same time, in the chemical raw material conveying system, it can be used to monitor the flow rate and pressure of materials in the pipeline and control the start and stop and rotation speed of the conveying pump to ensure the stable supply of raw materials. Power system monitoring: In the automation control system of a substation, it can be connected to various electrical quantity sensors (such as voltage transformers, current transformers, etc.) and switching equipment (such as circuit breakers, isolating switches, etc.). It can collect electrical parameters such as voltage, current, and power inside the substation in real time and transmit these data to the substation integrated automation system for analysis and processing. Through this module, the system can achieve remote control of the switching equipment, such as remotely controlling the opening and closing of circuit breakers, realizing real-time monitoring and protection of the power system, and improving the reliability and stability of the power system. In addition, in the generator set control system of a power plant, it can be used to monitor the operating parameters of the generator and control the excitation system and speed regulation system to ensure the stable operation of the generator and the quality of electrical energy.