Description

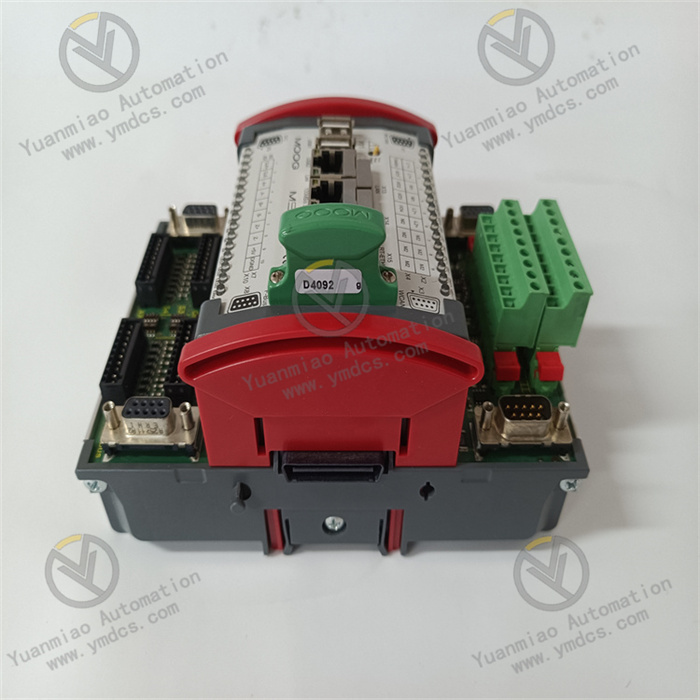

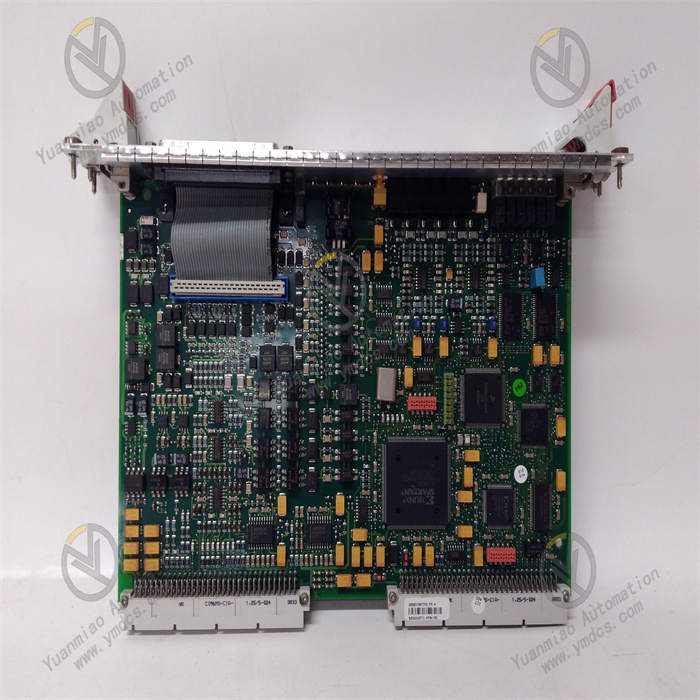

ABB PM877 3BDH000777R1

The ABB PM877 3BDH000777R1 is a controller module in the Advant series, typically applied in industrial automation control systems. With its powerful functions, high reliability, and flexible configuration capabilities, it has become a crucial control device in the field of industrial automation, helping users achieve efficient, stable, and intelligent production process control.

Functional Features

Strong Processing Capability

Equipped with a high-performance processor, it can quickly handle complex control tasks and a large number of input/output signals, enabling precise process control and real-time monitoring.

Rich Communication Interfaces

Supports multiple communication protocols such as Profibus, Modbus TCP, and Ethernet/IP, facilitating data interaction and system integration with other devices. It can seamlessly connect with supervisory control systems, other controllers, and field devices to build distributed control systems.

High Reliability

Adopts redundancy design, fault self-diagnosis, and fault-tolerant technologies to ensure stable operation in harsh industrial environments, reducing system downtime and improving production efficiency. For example, it has redundant power modules, communication links, and processors. When one component fails, the backup component automatically takes over to ensure system continuity.

Flexible Programming and Configuration

Using ABB's proprietary programming software such as Control Builder F, users can easily perform logic programming, function block configuration, and system parameter setting. It supports multiple programming languages such as Structured Text (ST), Ladder Diagram (LD), and Function Block Diagram (FBD) to meet different users' programming habits and application requirements.

Technical Parameters

Processor Performance

Likely employs a high-performance microprocessor with strong computing power and processing speed to handle complex control tasks and high-speed data processing needs, similar to the advanced microprocessor used in the PM876-1.

Memory Capacity

Features sufficient memory space for storing programs, data, and running complex control algorithms, ensuring stable and efficient system operation. Referencing the PM876-1, it has an ample memory capacity.

Communication Interfaces

May provide multiple communication interfaces, such as Ethernet ports for high-speed data transmission with upper computers, other controllers, or monitoring systems; and serial ports (e.g., RS-485) for connecting to traditional devices or modules with serial communication functions to enable data interaction and control command transmission. Referencing similar products like the PM876-1, it may also support communication interfaces such as onet, cnet, fnet, and dpv2.

Input/Output (I/O)

Offers configurable I/O options that can be flexibly adapted to different industrial control requirements. It may include digital input/output channels for receiving and controlling switching signals (e.g., device start/stop status, limit switch signals) and analog input/output channels for processing analog signals (e.g., temperature, pressure, flow sensor inputs) and analog control of actuators.

Power Specifications

Designed to adapt to standard industrial power supplies, it may support a wide voltage range to ensure stable operation in different industrial power environments, such as common 220V AC or other standard industrial voltages.

Operating Temperature Range

To adapt to various industrial field conditions, it generally has a wide operating temperature range, possibly between -20°C and +70°C, to ensure reliable operation in harsh industrial environments.

Protection Level

Considering industrial application scenarios, it may have a certain protection level, such as IP54 or higher, to prevent damage from dust, water vapor, etc., and ensure equipment stability and reliability in harsh environments.

Working Principle

1. Data Acquisition and Input Processing

- Input Interfaces: Receives field signals (e.g., temperature, pressure, switch status) through built-in or extended I/O modules (e.g., Analog Input AI, Digital Input DI).

- Signal Conditioning: Preprocesses input signals through filtering, amplification, and analog-to-digital conversion (A/D conversion) to ensure data accuracy.

- Real-Time Guarantee: Uses high-speed sampling technology to ensure timely response to dynamic signals (typical cycle in milliseconds).

2. Control Logic and Algorithm Execution

- Program Runtime Platform: Based on a Real-Time Operating System (RTOS) to ensure deterministic execution of control programs (no delays or priority preemption).

- Programming Language Support: Compatible with IEC 61131-3 standard programming languages (e.g., Ladder Diagram LD, Structured Text ST, Function Block Diagram FBD), allowing users to write control logic as needed.

- Algorithm Processing:

- Performs conventional logic control (e.g., interlock protection, sequential control).

- Supports advanced control algorithms (e.g., PID regulation, fuzzy control, complex mathematical operations).

- Handles specific algorithms for motion control or process control (e.g., motor speed regulation, process optimization).

3. Output Control and Execution

- Output Interfaces: Sends control commands through analog output (AO), digital output (DO), and other interfaces.

- Signal Conversion: Converts digital signals to analog signals (D/A conversion) or directly drives actuators such as relays and transistors.

- Closed-Loop Control: Forms a closed-loop control circuit by integrating feedback signals (e.g., real-time sensor data) to dynamically adjust outputs and achieve target parameters.

4. Communication and System Integration

- Internal Communication: Exchanges real-time data with expansion modules (e.g., I/O modules, communication modules) via backplane buses or dedicated interfaces.

- External Communication:

- Supports industrial Ethernet (e.g., PROFINET, EtherNet/IP, Modbus TCP) and fieldbus (e.g., PROFIBUS, CANopen) protocols.

- Communicates with upper computers (SCADA systems, HMI human-machine interfaces), other controllers, or cloud platforms to enable data monitoring, remote configuration, and system collaboration.

5. System Management and Diagnostics

- Real-Time Operating System (RTOS): Manages task scheduling, memory, and interrupt handling to ensure the stability of parallel multi-task operations.

- Fault Diagnosis:

- Built-in self-test functions (e.g., hardware fault detection, program runtime monitoring).

- Feeds back anomalies (e.g., communication interruptions, power failures, overloads) via LED indicators, diagnostic logs, or upper computer interfaces.

- Redundancy and Reliability: Some models support hot redundancy configuration (e.g., dual controllers backing up each other) to ensure system continuity in the event of single-point failures.

Application Fields

Manufacturing Industry

Used in production lines of automotive manufacturing, electronic device production, food and beverage processing, etc., to control the operation and coordination of robots, automated conveying systems, and production equipment, achieving automation and optimization of production processes.

Power Industry

Applied in automation control systems of power plants and substations to monitor and control generators, transformers, switchgear, etc., ensuring stable operation and efficient power supply of the power system.

Water Treatment Industry

Used in waterworks and wastewater treatment plants to control the operation of pumps, valves, aeration equipment, etc., achieving automated control and monitoring of water treatment processes to ensure effluent quality meets standards.

Chemical Industry

Used for reactor control, material transportation control, and monitoring/regulation of parameters such as temperature and pressure in chemical production processes to ensure the safety and stability of chemical production.