Description

Basic Information

Model: PM864AK01

Order Number: 3BSE018161R1

Brand: ABB

Order Number: 3BSE018161R1

Brand: ABB

Application Fields: Industrial automation control systems, especially suitable for the AC 800M controller platform and 800xA system. Commonly used in scenarios such as discrete manufacturing, process control, power, and chemical industries.

Functional Features

1. High-Performance Controller Core

- Processor: Equipped with a high-performance microprocessor, supporting fast logical operations, data processing, and real-time control to meet the real-time requirements of complex industrial processes.

- Memory Configuration: Features large-capacity RAM and flash memory, capable of storing large applications, historical data, and configuration files, supporting fast read/write operations and system restart recovery.

2. Rich Communication Capabilities

- Integrated Communication Interfaces:

- Supports industrial Ethernet protocols such as Ethernet/IP, PROFINET, and Modbus TCP for high-speed data interaction.

- Compatible with fieldbus protocols such as PROFIBUS DP and Modbus RTU, adapting to various third-party devices (e.g., sensors, drives, PLCs, etc.).

- Network Redundancy: Supports network redundancy configurations (e.g., ring topology) via dual Ethernet ports to ensure communication reliability and reduce downtime risks.

3. Real-Time Control and System Integration

- Real-Time Operating System (RTOS): Based on a hard real-time kernel, ensuring precise scheduling and response to control tasks (e.g., millisecond-level cycle periods).

- Collaboration with 800xA System: As the core controller of the 800xA distributed control system (DCS), it can seamlessly integrate HMI, I/O modules, safety systems, and third-party devices to achieve plant-wide automation management.

4. High Reliability and Environmental Adaptability

- Hardware Design: Adopts a compact and robust industrial-grade architecture, supporting DIN rail or rack mounting, and adapting to harsh environments such as vibration and electromagnetic interference (EMC).

- Operating Temperature Range: -20°C to +60°C, meeting the needs of high and low-temperature industrial scenarios.

- Redundancy Support: Supports controller redundancy configurations (e.g., hot standby redundancy), achieving master-backup switching through redundancy modules (e.g., PM864 redundancy kits) to enhance system availability.

5. Flexible Programming and Configuration

- Programming Languages: Supports IEC 61131-3 standard programming languages (e.g., Ladder Diagram LD, Structured Text ST, Function Block Diagram FBD, etc.), compatible with ABB Control Builder M or third-party development tools.

- Online Debugging and Updates: Supports online program modification and configuration downloads during runtime without shutdown, reducing maintenance time.

Technical Parameters

| Parameter Category | Specific Parameters |

|---|---|

| Processor | 32-bit high-performance microprocessor, main frequency ≥ [specific value refer to manual] (typically hundreds of MHz) |

| Memory | RAM: [X] MB; Flash: [Y] MB (may vary by version, refer to manual for confirmation) |

| Communication Interfaces | - 2×RJ45 Ethernet ports (10/100/1000Mbps) - Optional fieldbus interfaces (e.g., PROFIBUS DP) |

| Power Supply Voltage | DC 24V (typical value, specific range refer to manual) |

| Power Consumption | Low-power design, typical value ≤ [X] W |

| Dimensions (W×H×D) | Approximately [e.g., 100mm×200mm×150mm] (subject to actual product) |

| Weight | Approximately [e.g., 1.5kg] |

| Certifications | CE, ATEX (explosion-proof), IEC 61131-2, etc. (optional per application scenario) |

Application Scenarios

- Process Control: Continuous production control in chemical, pharmaceutical, and food/beverage industries (e.g., reactor and distillation column control).

- Discrete Manufacturing: Logical control and motion control for automotive production lines and semiconductor equipment.

- Power and Energy: Substation automation and monitoring systems for renewable energy (e.g., wind power, photovoltaics).

- Building Automation: Integration of HVAC, lighting, and security systems in large buildings.

Supporting Components and Systems

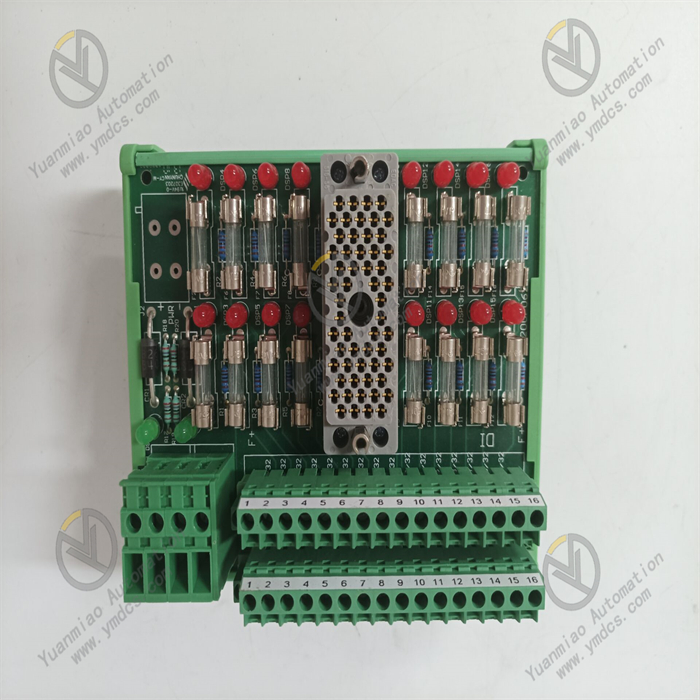

- I/O Modules: Paired with ABB CI series communication modules (e.g., CI855) and DI/DO/AI/AO modules (e.g., DI820, AO810) for field signal acquisition and control.

- Software Tools: Uses ABB Control Builder M for hardware configuration, programming, and debugging, and achieves system-level integration via 800xA Engineering Tool.

- Redundancy Solutions: Collaborates with redundant power modules (e.g., PS860), redundant backplanes (e.g., TB840), and redundant communication modules to build highly available systems.

Operation Guide for ABB PM864AK01 3BSE018161R1 Module

Installation

- Select Installation Location: Choose an installation location that meets the module’s requirements based on the actual application scenario, typically on a standard DIN rail. Ensure the surrounding environment complies with the module’s operating conditions, such as a temperature range of -10°C to 55°C and humidity of 5% to 95% (non-condensing).

- Fix the Module: Use the module’s built-in sliding and locking mechanism to securely attach the PM864AK01 to the DIN rail, ensuring it is firmly fixed to prevent loosening due to vibration or external forces.

- Connect Cables:

- Ethernet Connection: Use suitable Ethernet cables to connect to the control network via the two RJ45 Ethernet ports (CN1, CN2) on the backplane to enable communication with other devices.

- Serial Port Connection: If serial communication is required, connect the COM3 (RS232C port with modem control signals) or COM4 (isolated port for configuration tools) to other devices via appropriate cables according to specific needs.

Configuration

- Prepare Configuration Software: Install and open configuration software compatible with the module, such as ABB 800xA Control Builder.

- Create or Open a Project: Create a new project in the configuration software, or open an existing project for system maintenance or expansion.

- Add the Module to the Project: Locate and select the PM864AK01 module in the hardware configuration interface, then add it to the project.

- Set Parameters:

- Communication Parameters: Configure the module’s communication protocol (e.g., Profibus, Modbus, Ethernet), station address, baud rate, etc., according to actual communication needs to ensure compatibility with connected devices.

- Network Parameters: If the module is connected to a network via Ethernet, configure network parameters such as IP address, subnet mask, and gateway to enable proper network connectivity with other devices.

- Other Parameters: Depending on the application scenario, additional parameters such as data storage paths or real-time clock synchronization methods may need to be set.

- Download Configuration: After completing all parameter settings, download the configuration to the PM864AK01 module to make it operate according to the specified parameters.

Operation and Monitoring

- Start the System: After installation and configuration, power on the entire control system, including related power modules, other controllers, and connected devices, to ensure normal operation.

- Monitor Module Status:

- Indicator Lights: Observe the LED indicators on the module to understand its operating status. For example, the power indicator should be on, and the communication indicator may flash according to communication activity. Refer to the module manual for detailed interpretations of indicator colors and flashing frequencies.

- Software Monitoring: Use the monitoring interface in the configuration software to view real-time status information of the module, such as CPU usage, memory usage, and communication connection status.

- Data Communication Test: Perform simple data communication tests to verify whether the module can exchange data normally with other devices. For example, attempt to read data from or write data to other devices and check the accuracy and timeliness of data transmission.

- System Operation Monitoring: Continuously monitor the performance and status of the PM864AK01 module during system operation, including data processing speed and communication quality. If necessary, use diagnostic tools provided by the configuration software to conduct detailed diagnostics and analysis, and promptly address potential issues.

Maintenance and Care

- Regular Inspections: Regularly inspect the module’s appearance for damage, looseness, or overheating. Check that cables are securely connected and free from wear or corrosion. Additionally, clean any dust accumulation around the module’s installation location.

- Clean the Module: Clean the module’s casing with a soft dry cloth. Avoid using chemical cleaners or wet cloths to prevent damage. Pay special attention to keeping vents and cooling areas clean to ensure good heat dissipation.

- Backup Configuration: Regularly back up the module’s configuration information to quickly restore it to a previous normal state in case of faults or reconfiguration needs.

- Fault Handling: If a module fault occurs, first refer to the module’s fault code table or relevant manual to understand the specific cause and possible solutions. Perform troubleshooting and repairs as prompted by the fault information. If the issue is complex and cannot be resolved independently, contact ABB technical support for assistance.