Description

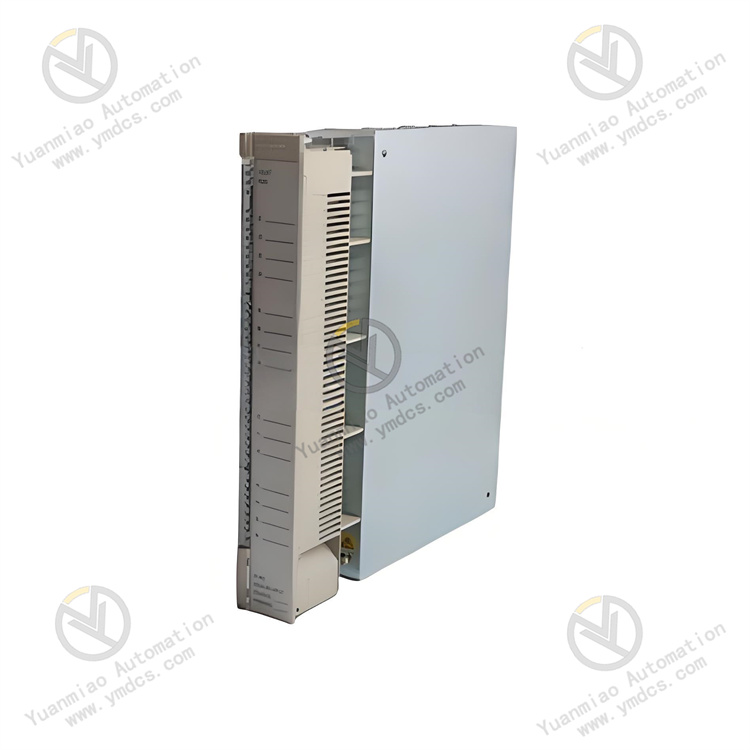

ABB DO620 3BHT300009R1

I. Overview

ABB DO620 3BHT300009R1 is a high-performance digital output module, with its core positioning as a precision signal conversion and drive terminal between industrial automation control systems and field execution devices. It is specially designed for industrial-grade signal output scenarios. The module can accurately receive digital control commands issued by the controller, convert the commands into output signals that can directly drive external execution devices through internal signal processing and drive circuits, realize start-stop control, status switching and interlock action triggering of various digital execution devices such as relays, contactors, solenoid valves and indicator lights, and provide stable and reliable signal output support for industrial process automation control in power, chemical industry, general manufacturing and other industries.

II. Product Features

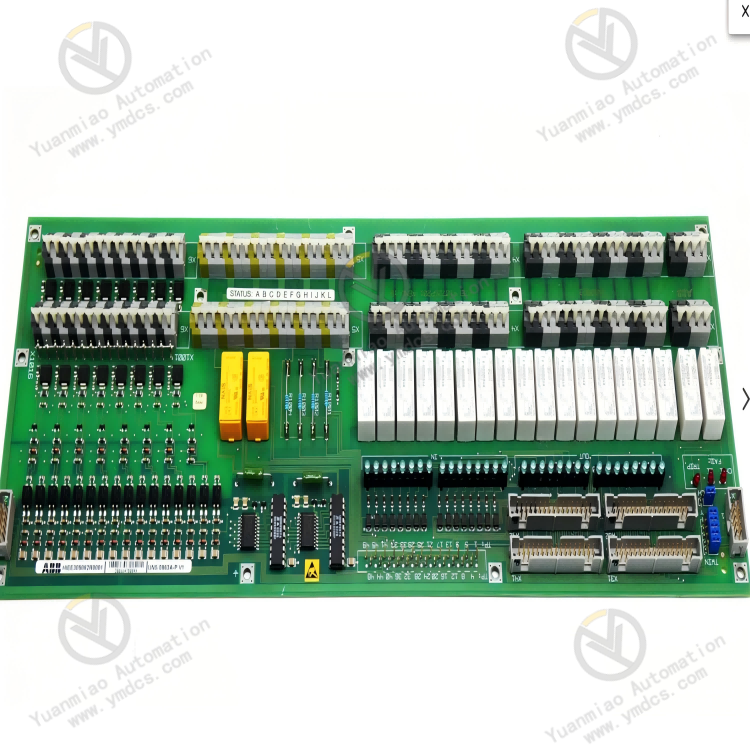

Optimized Channel Configuration: Adopting a high-density integrated channel design, it is equipped with 16 independent digital output channels (subject to the official manual). The channel layout is compact and reasonable, realizing multi-channel signal output in limited installation space. It can not only meet the signal output needs of general industrial scenarios, but also adapt to the centralized drive needs of small and medium-sized control systems, improving cabinet space utilization.

Stable and Reliable Output Capability: The 16 output channels are fully electrically isolated with an isolation voltage of ≥500V AC, which effectively blocks signal interference and crosstalk between channels, ensuring the stability and accuracy of output signals. It supports multiple output modes, is compatible with PNP/NPN drive types, and source/sink output is selectable, which can flexibly adapt to field execution devices with different load characteristics and improve the versatility of the module.

Wide System Compatibility: Specially designed for ABB industrial automation control system architecture, it can seamlessly connect with a variety of controllers such as AC series and supporting communication interface modules. It realizes high-speed data interaction with the controller through standardized communication protocols such as PROFIBUS DP, with low data transmission delay and high reliability. It supports multi-module cascade expansion, can flexibly expand capacity according to system requirements, and has good system compatibility and expandability.

Full-Dimensional Diagnosis Function: Built-in a complete self-diagnosis and real-time monitoring mechanism, it can monitor the module power supply status, output voltage/current status of each channel, communication link integrity and external execution device connection status around the clock. When a fault is detected, it can quickly and accurately locate the faulty channel and fault type (such as overload, short circuit, communication interruption, etc.), intuitively prompt the fault status through local indicator lights, and upload standardized fault information to the controller and upper computer system through the communication bus, providing clear fault handling basis for operation and maintenance personnel and shortening fault troubleshooting time.

Strong Environmental Adaptability and Protection Performance: Adopting industrial-grade core components and enhanced circuit design, it has passed strict Electromagnetic Compatibility (EMC) certification. The operating temperature range covers -25℃~+60℃, enabling stable operation in wide-temperature environments. It has excellent vibration resistance (2g, 10Hz~150Hz) and shock resistance (10g, 11ms) performance, and can adapt to the vibration environment of industrial sites. Each output channel is built-in with overcurrent protection, short-circuit protection and reverse polarity protection circuits, which can effectively protect the module and external execution devices from damage and improve the safety of system operation.

- Convenient Operation and Maintenance Design: Supporting module-level online hot swap function, it can complete module installation, replacement and maintenance without interrupting the overall system operation, greatly reducing production losses caused by system downtime. Equipped with clear local status indicator lights (power supply, operation, communication, channel group fault), operation and maintenance personnel can quickly judge the overall operation status of the module through the indicator lights, and accurately locate single-channel faults combined with the upper computer system, improving operation and maintenance efficiency.

III. Technical Parameters

1. Core Basic Parameters

- Product Model: ABB DO620 3BHT300009R1

- Product Type: High-performance digital output module

- Manufacturer: ABB Group

- Product Series: I/O component of ABB industrial automation control system

- Core Functions: Receive digital commands from the controller, signal conversion and amplification, drive field execution devices, monitor channel status, full-dimensional fault diagnosis and alarm

- Communication Method: Communicate with the controller via PROFIBUS DP bus (matching corresponding communication interface module is required)

- Applicable System: ABB AC series and other industrial automation control systems

- Application Fields: Power industry (substation auxiliary control, power generation equipment supporting), chemical industry (process control execution unit), general manufacturing (production line equipment drive), municipal engineering (large pumping station, sewage treatment equipment), metallurgical industry (auxiliary equipment control), etc.

2. Electrical Performance Parameters

- Supply Voltage: 24V DC (voltage fluctuation range: 20.4V DC ~ 28.8V DC)

- Output Type: Digital output, compatible with PNP/NPN drive types, source/sink output selectable

- Channel Quantity: 16 independent digital output channels (fully isolated between channels, isolation voltage ≥500V AC)

- Output Voltage Range: Rated output 24V DC (suitable for most industrial execution devices)

- Output Current: Maximum output current per channel ≤2A (subject to the official manual); total output current of the module ≤16A

- Output Response Time: Flexibly configurable through configuration software, minimum ≤1ms, maximum ≤100ms, adapting to control scenarios with different response speed requirements

- Output Protection: Overcurrent protection, short-circuit protection, reverse polarity protection

- Fault Diagnosis Range: Channel short circuit, output overload, power supply voltage abnormality, communication link interruption, channel open circuit, execution device fault

- Communication Interface: Connect with communication interface module (such as CI854) via I/O bus

- Communication Protocol: Support PROFIBUS DP V1/V2 protocol

- I/O Expansion Capability: Support cascade expansion of up to 32 same-series I/O modules, with a maximum expandable I/O point count of 512

- Driven Device Type: Field relays, AC contactors, DC solenoid valves, industrial indicator lights, small drive pumps, fans, electromagnetic clutches and other digital execution devices

3. Environmental and Physical Parameters

- Operating Temperature: -25℃~+60℃

- Storage Temperature: -40℃~+85℃

- Relative Humidity: 5%~95% RH (no condensation)

- Vibration Resistance: 2g, 10Hz~150Hz (sine wave), compliant with IEC 60068-2-6 standard

- Shock Resistance: 10g, 11ms (half-sine wave), compliant with IEC 60068-2-27 standard

- Protection Grade: IP20 (module itself); IP54 (when installed in standard industrial cabinet)

- Weight: Approximately 0.8kg (module itself); 2.5kg (including transportation package)

- Installation Method: Rack-mounted installation (adapt to ABB standard I/O cabinet, compliant with IEC 60917 standard)

- Dimensions (Length × Width × Height): 160mm × 105mm × 60mm (subject to the official manual)

- Special Functions: Online hot swap, independent channel isolation, full-dimensional online diagnosis, signal filtering, overcurrent/short-circuit/reverse polarity protection

IV. Working Principle

The core working principle of ABB DO620 3BHT300009R1 is a closed-loop workflow of command receiving - signal processing - drive output - status feedback - fault diagnosis. Through the coordinated operation of the communication receiving unit, signal processing unit, output drive unit and fault diagnosis unit inside the module, it realizes accurate conversion of controller commands and reliable driving of field execution devices. The specific working process can be divided into five core stages:

Stage 1: System Initialization and Parameter Configuration StageAfter the module establishes a connection with the communication interface module of the ABB controller via the I/O bus and is connected to the 24V DC power supply, it automatically completes initialization and startup, performs internal circuit self-test, calibrates 16 output channels one by one and verifies the integrity of the communication link. Operation and maintenance personnel complete the basic configuration of output response time, fault diagnosis threshold (such as overcurrent threshold), output type (PNP/NPN) and communication parameters through ABB special configuration software (such as Control Builder M), ensuring that the module is accurately adapted to the controller and field execution devices, and meets the response requirements of specific control scenarios.

Stage 2: Controller Command Receiving StageAccording to the logic operation results of the industrial process, the controller transmits digital control commands (such as equipment start-stop and status switching commands) to the communication interface module via the PROFIBUS DP bus. The communication interface module converts the commands into a format recognizable by the I/O bus and transmits them to the communication receiving unit of the DO620 module. The receiving unit performs preliminary verification on the commands, filters invalid commands and interference signals, ensuring the accuracy of command transmission.

Stage 3: Signal Processing and Amplification StageThe verified control commands are transmitted to the signal processing unit inside the module, which converts the commands into standardized drive signals. For execution devices with different load characteristics, the drive circuit amplifies the power of the standardized signals to ensure that the output signals have sufficient driving capacity to stably drive relays, solenoid valves and other devices to act.

Stage 4: Output Driving and Status Collection StageThe amplified drive signals are transmitted to the corresponding field execution devices through 16 independent output channels, triggering the devices to complete preset actions (such as relay pull-in, solenoid valve opening). Meanwhile, the module real-timely collects the output voltage and current signals of each output channel, records the channel working status, and provides real-time data support for subsequent status monitoring and fault diagnosis.

V. Common Fault Troubleshooting

1. No Signal Output/Output Abnormality in Partial/All Output Channels

2. Frequent Fault Alarms/False Alarms of Output Channels

3. Abnormal Communication Between Module and Controller

4. Module Fails to Start/Power Indicator Has No Response