Description

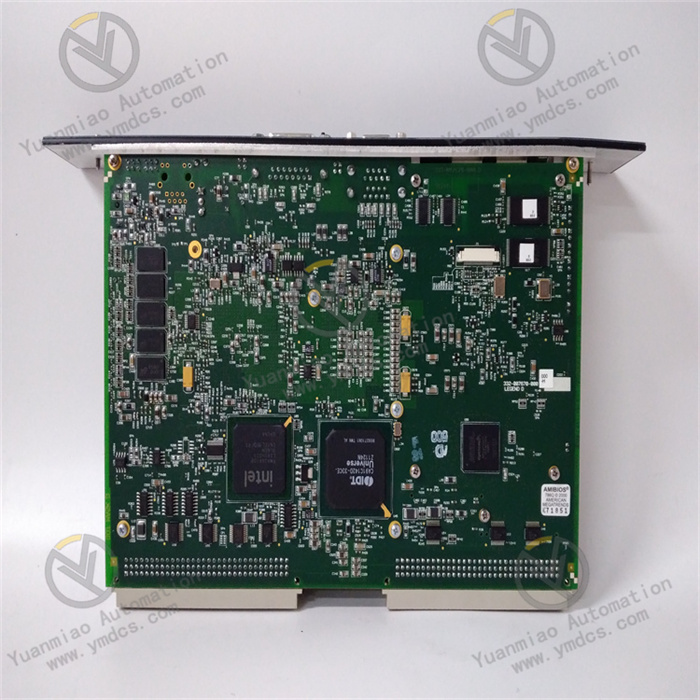

GE Fanuc IC698CPE030

I. Overview

GE Fanuc IC698CPE030 is a mid-range high-performance processor module under the PACSystems RX7i series, specifically designed to meet the core control requirements of medium and large-scale industrial automation systems (such as process industrial control, discrete manufacturing production lines, and regional-level equipment cluster management and control). Its core positioning is to serve as the "control center" of the system. By integrating logical control, process control, data processing, and multi-protocol communication functions, it realizes the precise scheduling of equipment actions, real-time regulation of process parameters, and collaborative linkage between multiple systems in complex industrial scenarios. As a key component balancing "performance, cost, and reliability", it is widely applicable to fields with clear requirements for control accuracy and system stability, such as power, chemical engineering, and automotive parts manufacturing.

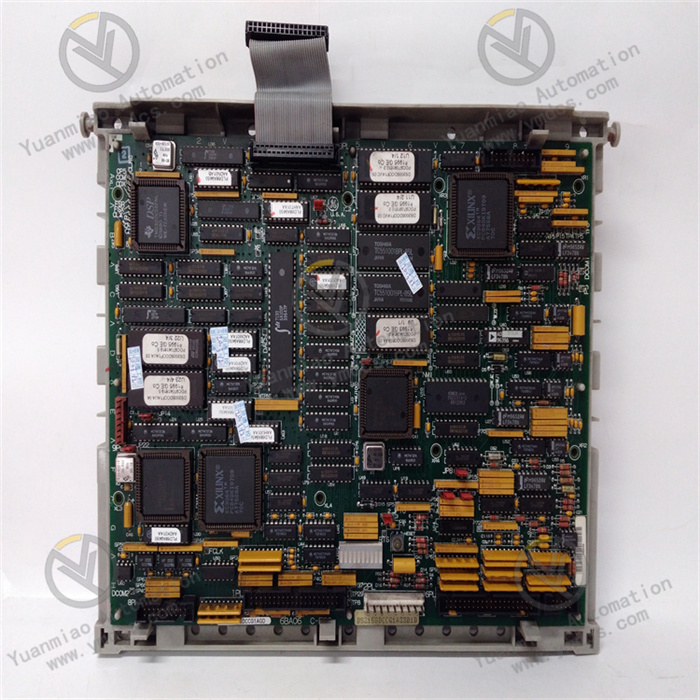

- It adopts a modular hardware architecture, compatible with all types of I/O modules and function expansion modules in the RX7i series, enabling flexible upgrades without system reconstruction.

- Equipped with an industrial-grade processor and an optimized real-time operating system (RTOS), it can process logical operations, analog control, and communication tasks in parallel, meeting the multi-task concurrency requirements of medium and large-scale systems.

- Meanwhile, it features wide temperature adaptability, strong electromagnetic interference resistance, and redundancy expansion capabilities, allowing continuous and stable operation in industrial sites with high dust levels, large temperature fluctuations, and strong electromagnetic interference.

II. Technical Specifications

(I) Core Performance Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Processor | Intel Celeron M processor, with a clock speed of 1.0GHz, supporting hardware floating-point operations, and a single-cycle instruction execution efficiency of ≥1.2 MIPS/MHz |

| Memory Configuration | 32MB RAM (for program operation and real-time data caching); 32MB non-volatile Flash (for program and parameter storage, supporting data retention for ≥10 years after power-off) |

| Control Cycle | Logical control cycle ≤1ms, analog control cycle ≤2ms, data acquisition cycle ≤500μs, meeting the real-time requirements of medium and large-scale systems |

| Program Storage Capacity | Supports a maximum of 16MB user program storage, capable of accommodating over 5,000 function block programs or 100,000 lines of ladder diagram code |

| Data Processing Capacity | Supports simultaneous data operations for 1,024 analog channels and 4,096 digital channels, and is compatible with algorithms such as PID, fuzzy control, and ramp/curve control |

(II) Communication and Interface Parameters

- Ethernet Interface: 2 channels of 10/100Mbps adaptive Ethernet interfaces (in RJ45 form), supporting TCP/IP, Modbus TCP/IP, and EtherNet/IP protocols, as well as network redundancy (MRP protocol), with a communication delay of ≤10ms.

- Serial Communication Interface: 2 channels of switchable RS-232/RS-485 serial ports (configurable via software), supporting Modbus RTU and DF1 protocols, with a baud rate range of 1200-115200bps, and supporting parity check and data bit adjustment.

- Expansion Interface: 1 channel of high-speed backplane bus interface (with a rate of 1Gbps), supporting connection to RX7i series I/O modules, communication expansion modules, and motion control modules, with a maximum expansion distance of ≤10m (single segment).

- External Storage Interface: 1 channel of microSD card interface (supporting a maximum capacity of 32GB), used for program backup, data log storage, and firmware upgrade.

(III) Power Supply and Physical Parameters

- Power Supply Requirements: 5VDC±5% bus power supply, operating current ≤1.5A, power consumption ≤7.5W (under full-load conditions), supporting reverse power connection protection (no damage under reverse voltage of ≤12V DC).

- Physical Dimensions: 125mm (length) × 311mm (width) × 63.5mm (height), compatible with standard racks of the RX7i series, occupying 1 module slot, with a weight of approximately 0.45kg.

- Installation Method: 35mm DIN rail mounting or panel embedded mounting (dedicated mounting brackets required), with a spacing of ≥10mm between modules to ensure heat dissipation.

(IV) Environmental and Reliability Parameters

- Operating Temperature Range: -20℃~+60℃, supporting low-temperature startup (no preheating required in -20℃ environment, startup time ≤30s).

- Storage Temperature Range: -40℃~+85℃, humidity range 5%~95% (no condensation).

- Electromagnetic Interference Resistance: Compliant with the EN 61000-6-2 industrial immunity standard; ESD (Electrostatic Discharge) protection level of ±8kV (contact)/±15kV (air); radiation immunity level of 3V/m (80MHz~1GHz).

- Mean Time Between Failures (MTBF): ≥60,000 hours (compliant with the MIL-HDBK-217 standard, in 25℃ environment).

- Certification Standards: CE (EN 61010-1), UL (UL 508), RoHS 2.0.

III. Functional Features

(I) Balanced Computing Performance and Multi-Task Processing

Multi-Task Parallel Processing

Integration of Complex Algorithms

Data Processing Capacity

(II) Flexible Expansion and System Compatibility

I/O Expansion Capacity

Third-Party Equipment Compatibility

Redundancy Expansion Support

(III) Industrial-Grade Reliability and Convenient Operation & Maintenance

Hardware Protection and Stability

- The circuit adopts a "power isolation (isolation voltage ≥2500Vrms) + signal filtering" design to suppress power grid fluctuations and electromagnetic interference. Near a frequency converter (with an output power of 50kW) (electromagnetic radiation ≥8V/m), the analog acquisition error is ≤0.5% F.S. without data jumps.

- The shell is made of flame-retardant ABS material (compliant with the UL94 V-0 standard) with an IP20 protection level, which can resist dust intrusion in the workshop. A temperature sensor is installed inside the module; when the core temperature is ≥70℃, it automatically triggers derated operation to avoid hardware damage caused by high temperatures.

Intelligent Fault Diagnosis

Convenient Operation & Maintenance Design

- The panel is equipped with 4 LED indicators (power, operation, fault, communication) to intuitively display the working status of the module; a built-in microSD card interface supports local program backup/restoration (backup time ≤2 minutes) to prevent program loss.

- It supports remote debugging via Proficy Machine Edition software. Engineers can connect to the module via Ethernet to download programs, modify parameters, and read fault logs without on-site attendance. For example, when a "program logic error" occurs in a module at a remote factory, remote engineers can modify the program online through the software without dispatching personnel to handle it on-site, reducing operation and maintenance costs by 30%.

(IV) Data Interaction and Industrial Internet Connection

Industrial Protocol Support

Edge Computing Capability

Secure Communication Mechanism