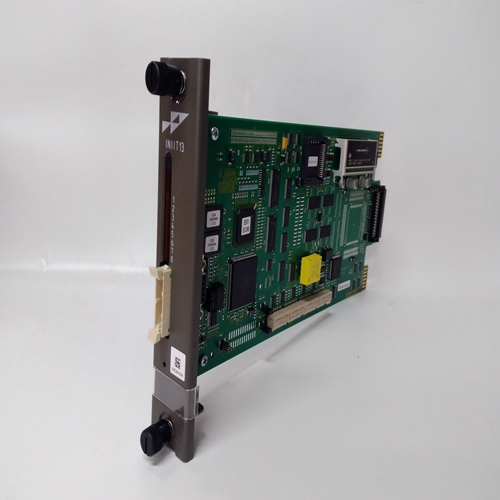

Description

GE Fanuc IC698PSA100

I. Overview

GE Fanuc IC698PSA100 is a high-performance industrial-grade power supply module specifically designed for the RX3i series PLC systems. Its core positioning is to serve as the "stable power supply core" of the system, focusing on addressing the reliable power supply needs of PLCs and expansion modules in industrial scenarios. Through wide voltage input, efficient power conversion, and redundant backup design, it provides stable DC power for CPU modules (such as IC698CPE040-JP), I/O modules (such as IC698MDL645), and special function modules, ensuring the continuous and stable operation of the entire PLC system in complex industrial environments.

This module has core advantages of "wide voltage input + efficient conversion + strong environmental resistance":

- It supports a wide AC input range of 85V AC~264V AC, adapting to power grid voltages in different regions around the world (e.g., 220V AC in China, 110V AC in the United States) without the need for additional voltage regulation equipment.

- It has an output power of 100W and provides a stable output of 24V DC/3.3A, which can supply power to modules in 1 CPU rack and 2 expansion racks simultaneously.

- Meanwhile, it features wide temperature adaptability (0℃~+60℃), electromagnetic interference resistance, and overload/short-circuit protection design, enabling continuous and stable operation in complex industrial environments such as automobile manufacturing, food and beverage production, and electronic equipment assembly.

Compared with ordinary switching power supplies, it has significant advantages in voltage adaptability, anti-interference capability, and compatibility with PLC systems. Compared with high-power power supplies in the same series (such as IC698PSA200), it has a more compact size and lower cost, making it suitable for small and medium-sized PLC systems. It is a key power supply component for building RX3i series PLC systems.

As a standard power supply module of the RX3i series, IC698PSA100 is widely used in scenarios such as auto parts welding lines, food filling production lines, and electronic component testing equipment. It provides "safe, stable, and efficient" power supply support for PLC systems and is a key technical equipment to ensure the uninterrupted operation of industrial automation systems and avoid production interruptions caused by power supply abnormalities.

II. Technical Specifications

(I) Core Power Supply and Conversion Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Input Voltage and Frequency | AC input: 85V AC~264V AC (wide range), frequency 47Hz~63Hz (compatible with 50Hz/60Hz global power grids); supports DC input (optional: 120V DC~370V DC), adapting to DC power supply scenarios (such as battery backup systems) |

| Output Parameters | Main output: 24V DC/4.2A (rated power 100W), output voltage accuracy ±2% (under full load condition); ripple and noise ≤50mVp-p (within 20MHz bandwidth) to ensure stable operation of sensitive modules (such as analog I/O) |

| Power Conversion Efficiency | Conversion efficiency ≥85% under typical load (50%~100% load), efficiency ≥75% under light load (20% load); low-power design reduces heat generation and lowers heat dissipation costs |

| Redundancy and Parallel Connection | Supports parallel redundant operation of 2 modules (requires configuration of redundant cables); total output current after parallel connection is 8.4A, and redundancy switching time ≤1ms to ensure uninterrupted system power supply when a single module fails |

(II) Protection and Safety Parameters

- Protection Functions: Equipped with overvoltage protection (triggered when output voltage ≥28V DC), overcurrent protection (current limiting when output current ≥5A), short-circuit protection (immediately cuts off output when output is short-circuited, and automatically recovers after fault elimination), and overtemperature protection (reduces output when internal module temperature ≥85℃, and shuts down when temperature ≥95℃). Multiple protections prevent damage to the module and loads.

- Safety Certifications: Complies with UL 508 safety standard for industrial control equipment and EN 61010-1 safety standard for measurement and control equipment; insulation strength: input to output/ground ≥3000Vrms (for 1 minute), leakage current from output to ground ≤3.5mA (under 250V AC input), ensuring the safety of operators and equipment.

- EMC Compatibility: Complies with EN 61000-6-2 industrial immunity standard; radio frequency radiation (EN 61000-6-3) ≤40dBμV/m (30MHz~1GHz), radio frequency immunity (EN 61000-6-2) ≥10V/m (80MHz~1GHz), preventing electromagnetic interference from the power supply module to the PLC system while resisting external interference.

(III) Physical and Installation Parameters

- Physical Dimensions: Adopts the standard rack-mounted design of the RX3i series; dimensions (length × width × height) are 120mm×80mm×150mm, adapting to RX3i standard racks (such as IC698CHS010). It can be installed side by side with CPU modules and I/O modules, saving control cabinet space.

- Installation Method: DIN rail mounting (compatible with DIN 35mm standard rails) or screw fixing; installation torque ≤2N・m to avoid damaging the module housing due to over-tightening; module weight ≤500g, lightweight design facilitating installation and maintenance.

- Heat Dissipation Method: Natural convection heat dissipation (no fan required); the housing adopts an aluminum alloy heat dissipation structure with high heat dissipation efficiency. When operating at full load in a 60℃ environment, the module surface temperature ≤75℃, with no overheating risk.

(IV) Environmental and Reliability Parameters

- Operating Environment: Operating temperature range 0℃~+60℃, storage temperature range -40℃~+85℃; humidity range 5%~95% (non-condensing, complying with IEC 60068-2-3 standard); altitude ≤2000m (derating is required when exceeding this altitude, with output power derated by 10% for every 1000m increase).

- Vibration and Shock Resistance: Vibration resistance rating 5g (10Hz~500Hz, complying with IEC 60068-2-6), shock resistance rating 20g (11ms pulse, complying with IEC 60068-2-27), adapting to vibrations from workshop equipment and shocks during installation and maintenance.

- Reliability Index: Mean Time Between Failures (MTBF) ≥100,000 hours (per Telcordia SR-332 standard, under 25℃ environment); design life ≥10 years, reducing replacement frequency and maintenance costs.

III. Functional Features

(I) Wide Voltage Input and Global Adaptation to Break Through Power Grid Limitations

With "85V AC~264V AC wide voltage input" as its core, GE Fanuc IC698PSA100 adapts to different global power grid environments:

- Compatibility with Multiple Voltage Scenarios: The module can adapt to power grids in different regions without replacement. For example, in an auto parts factory in China (220V AC/50Hz), the module is directly connected to the power grid; in a factory in Mexico (127V AC/60Hz), the module automatically adapts to the input voltage and provides stable 24V DC power supply without a voltage regulating transformer, avoiding module damage caused by voltage mismatch.

- DC Input Expansion: Optional DC input function adapts to special power supply scenarios. For example, in the PLC control system of a communication base station in a remote area, when the power grid is unstable, it can switch to battery DC power supply (220V DC), and the module continuously outputs 24V DC to ensure the uninterrupted operation of the base station equipment monitoring system.

- Adaptation to Power Grid Fluctuations: When the input voltage fluctuates within ±15% (e.g., the power grid voltage drops from 220V AC to 187V AC), the output voltage fluctuation ≤±1% (24V DC fluctuation ≤0.24V), ensuring that the collection and control accuracy of PLC modules (such as analog I/O) is not affected and avoiding logic misjudgment caused by voltage fluctuations.

(II) Efficient Conversion and Low-Consumption Heat Dissipation to Reduce Operating Costs

The module achieves efficient power conversion and low heat generation through optimized circuit design:

- High Conversion Efficiency: A conversion efficiency of over 85% reduces energy waste. For example, the PLC system of a food filling production line requires 100W power supply, and the module operates for 8000 hours (about 1 year). Compared with an ordinary power supply with a conversion efficiency of 70%, it can save electric energy: 100W×(85%-70%)×8000h=120kWh, reducing the enterprise's electricity cost.

- Fanless Mute Heat Dissipation: The natural convection heat dissipation design has no mechanical wear, avoiding module overheating caused by fan failure. For example, in an electronic component testing workshop (sensitive to noise), the module operates quietly (noise ≤30dB) without affecting the workshop environment; at the same time, there is no problem of fan dust accumulation, and no fan cleaning is required during long-term operation, reducing maintenance workload.

- Stable Derating at Wide Temperatures: In high-temperature environments (e.g., 60℃), the module automatically derates to 80% output (24V DC/3.36A), which can still meet the power supply needs of small and medium-sized PLC systems. For example, in an automobile workshop in southern China in summer (ambient temperature 55℃), the module can supply power to 1 CPU rack and 1 expansion rack after derating, ensuring normal system operation with no risk of overheating shutdown.

(III) Multiple Protections and Redundant Backup to Ensure Power Supply Safety

The module avoids system failures caused by power supply abnormalities through multiple protection mechanisms and redundant design:

- Full-Scenario Fault Protection: Overvoltage/overcurrent/short-circuit/overtemperature protection covers various risks. For example, when the output end is short-circuited due to wiring errors, the module immediately cuts off the output (short-circuit current ≤1A) to avoid burning the PLC module; after the short-circuit is eliminated, the module automatically resumes power supply without manual restart, reducing downtime.

- Two-Module Redundant Operation: Supports parallel redundancy to improve system reliability. For example, in the PLC control system of a chemical reaction kettle, 2 IC698PSA100 modules supply power in parallel. Under normal conditions, each module bears 50% of the load (24V DC/2.1A); when one module fails, the other module switches to full load (24V DC/4.2A) within 1ms, ensuring uninterrupted control of the reaction kettle and avoiding production accidents caused by power supply failures.

- Insulation and Leakage Current Prevention: 3000Vrms insulation strength and low leakage current ensure personnel safety. For example, in a humid food processing workshop, the insulation between the module input and output/ground is good, and the leakage current ≤3.5mA, avoiding the risk of electric shock for operators and complying with industrial safety standards.

(IV) Convenient Installation and Status Monitoring to Simplify Operation and Maintenance Management

The module design facilitates installation and real-time status checking, reducing operation and maintenance difficulty:

- Standard Rack Compatibility: Adapts to RX3i standard racks, requiring no additional brackets for installation. For example, during PLC system assembly, the module can be directly inserted into the IC698CHS010 rack and forms a compact layout with CPU modules and I/O modules, saving control cabinet space; the rail mounting method can also flexibly adapt to non-standard rack scenarios.

- LED Status Indication: The panel is equipped with 3 LED indicators (power input, normal output, fault) to intuitively display the working status. For example, "input light on + output light on" indicates normal power supply; "fault light flashing" indicates overtemperature/overvoltage/overcurrent. Maintenance personnel can quickly determine the fault type without professional instrument testing, reducing maintenance time by 50%.

- Remote Status Feedback: Supports reading module status through PLC (requires expansion of communication module). For example, in the central control room, the HMI is used to monitor the power supply module's "output voltage (24.2V)", "output current (1.8A)", and "module temperature (45℃)" in real time, and early warning of abnormalities (such as output voltage dropping to 23V) is provided, allowing maintenance personnel to proactively troubleshoot and avoid sudden failures.