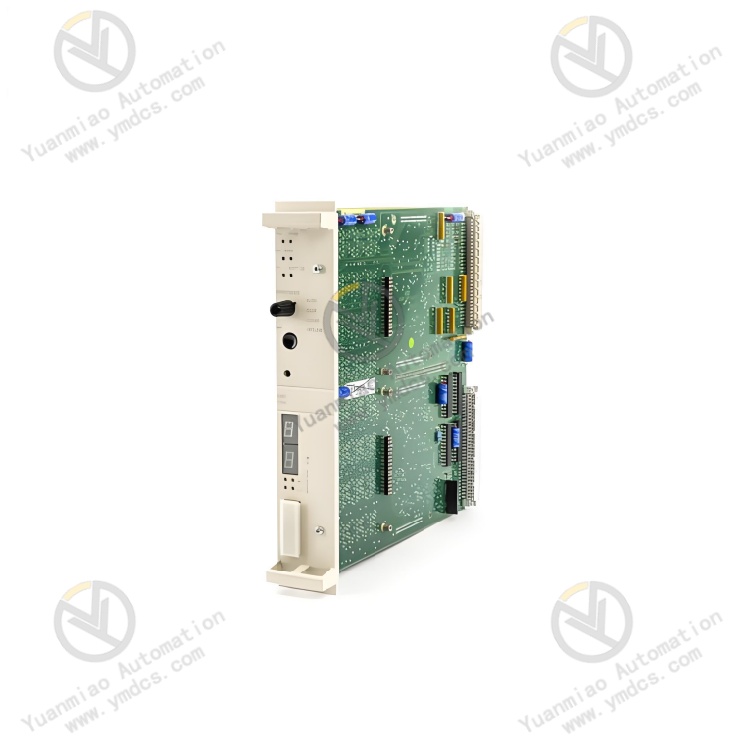

Description

ABB 07KR51 1SBP260011R1001

I. Functional Positioning and Application Scenarios

Positioning:

It belongs to the distributed I/O module in ABB's industrial automation system, mainly used to expand the input/output (I/O) capability of the system. It is compatible with controllers such as ABB AC 800M and Advant Controller 400 series, supports cascading with PLC and DCS systems, and is suitable for signal acquisition and control in medium to large industrial automation scenarios.

It belongs to the distributed I/O module in ABB's industrial automation system, mainly used to expand the input/output (I/O) capability of the system. It is compatible with controllers such as ABB AC 800M and Advant Controller 400 series, supports cascading with PLC and DCS systems, and is suitable for signal acquisition and control in medium to large industrial automation scenarios.

Typical Scenarios:

- Process Control: Collecting and regulating analog signals such as temperature, flow, and liquid level in petrochemical and power industries.

- Equipment Automation: Accessing devices like encoders and pressure sensors in metallurgical production lines, or driving actuators such as servo motors and solenoid valves.

- System Integration: Enabling distributed data interaction with main controllers or host computers (e.g., ABB Freelance) via protocols such as Profibus and EtherNet/IP.

II. Functional Features

I/O Channel Configuration and Characteristics

- Analog Input (AI): 8 channels, supporting signal types including 4-20mA, 0-10V, PT100/PT1000 thermal resistors, and thermocouples (types K/J/T, etc.), with 16-bit high-precision sampling and electrical isolation (strong anti-interference capability).

- Analog Output (AO): 4 channels, outputting 4-20mA or 0-10V, supporting loads ≤500Ω, and capable of driving precision devices such as control valves and frequency converters.

- Digital Input/Output (DI/DO): 8 channels each. DI supports 24V DC/110V DC level detection (response time ≤1ms), and DO is transistor output (24V DC/0.5A), suitable for high-frequency switching control (e.g., pulse signals).

Communication and Compatibility

- Standard with Profibus DP V1 interface, optional EtherNet/IP, Modbus RTU, etc., supporting high-speed communication with third-party devices.

- Supports hot-swapping, allowing module replacement during system operation to reduce downtime.

Reliability Design

- Wide-temperature Operation: -40°C to +70°C, adapting to harsh industrial environments (e.g., outdoor areas, high-temperature workshops).

- Electrical Isolation: Isolation voltage ≥3000V AC between I/O channels and CPU, resistant to electromagnetic interference (compliant with EN 61000-6-2 standards).

- Redundancy Support: Dual-power modules (24V DC redundant power supply) supporting seamless switching during power failures.

III. Technical Parameters

| Parameter Type | Specific Indicators |

|---|---|

| Processor | 32-bit microprocessor, 48MHz (optimized for high-speed data processing) |

| Memory | 4MB program memory, 2MB data memory (supports complex control logic and real-time data caching) |

| Analog Input | 8 channels, 16-bit accuracy, supporting 4-20mA/0-10V/PT100/thermocouples, input impedance ≥10MΩ |

| Analog Output | 4 channels, 16-bit accuracy, 4-20mA/0-10V, maximum load 500Ω |

| Digital Input/Output | DI: 8 channels (24V/110V DC, response time ≤1ms); DO: 8 channels (transistor, 24V DC/0.5A) |

| Communication Interfaces | Standard Profibus DP V1, optional EtherNet/IP, Modbus RTU |

| Power Supply | 24V DC (±20%), power consumption ≤15W |

| Mechanical Characteristics | Dimensions: 170mm×100mm×70mm, weight: 0.7kg |

IV. Working Principle

Signal Processing Flow

- Input Stage: AI channels convert sensor signals (e.g., millivolt signals from thermocouples) into digital quantities via high-precision ADC, while DI channels detect switch states in real time.

- Output Stage: The module receives commands from the main controller, outputs analog signals via AO (e.g., controlling frequency converter speed) or pulse signals via DO (e.g., controlling servo motor start/stop).

- Communication Interaction: Synchronizes data in real time with the main controller via Profibus or Ethernet, supporting periodic data transmission and aperiodic parameter configuration.

System Integration Mode

- As a distributed I/O module, it can be cascaded on the expansion bus of the main controller (e.g., ABB AC 800M), supporting up to 256 I/O points expansion.

- Supports communication with third-party intelligent devices (e.g., flowmeters, analyzers) via standard protocols to achieve cross-brand system integration.

V. Troubleshooting Guide

Abnormal I/O Signals

- Phenomenon: AI data fluctuates or deviates significantly; DO has no output.

- Troubleshooting: Check for loose sensor connections, verify if signal types and ranges match in the module configuration software (e.g., incorrect thermocouple type selection), and test channel hardware via diagnostic tools.

Communication Interruption

- Phenomenon: The main controller reports "module offline", and the communication indicator (BUS LED) is off.

- Troubleshooting: Check for short circuits/opens in Profibus cables, ensure terminal resistors (120Ω) are connected, confirm module addresses match the configuration, and try replacing the communication interface or network segment.

Power Failure

- Phenomenon: The power indicator (POWER LED) flashes or goes off, and the module restarts frequently.

- Troubleshooting: Measure the power voltage within 19.2-28.8V DC, check for oxidized power terminals, and confirm normal switching between main and backup power supplies for redundant systems.

VI. Typical Application Cases

Photovoltaic Power Plant Monitoring System

- AI channels access PT100 to monitor panel temperature and 4-20mA to collect inverter current/voltage; AO controls cooling fan speed; DI monitors circuit breaker status; DO triggers alarm devices, with real-time data transmission to the host computer via EtherNet/IP.

Automotive Painting Production Line

- DI accesses photoelectric sensors to detect vehicle positions; DO controls painting robot start/stop; AI collects paint pressure and flow signals, communicating with PLC via Profibus to achieve precise closed-loop control of the painting process.

VII. Comparison with Similar Products (vs ABB 07KR31)

| Parameter Dimension | ABB 07KR31 | ABB 07KR51 |

|---|---|---|

| Analog Input Precision | 12-bit | 16-bit (higher precision) |

| Signal Type Support | No thermocouple support | Supports thermocouples, PT1000, etc. |

| Digital Output Type | Relay (250V AC/2A) | Transistor (24V DC/0.5A, high-frequency response) |

| Communication Protocol | Standard Modbus RTU | Standard Profibus DP V1 (high-speed industrial bus) |

| Application Scenarios | Medium systems (normal precision) | Large systems, high-precision control (e.g., precision measurement) |