Description

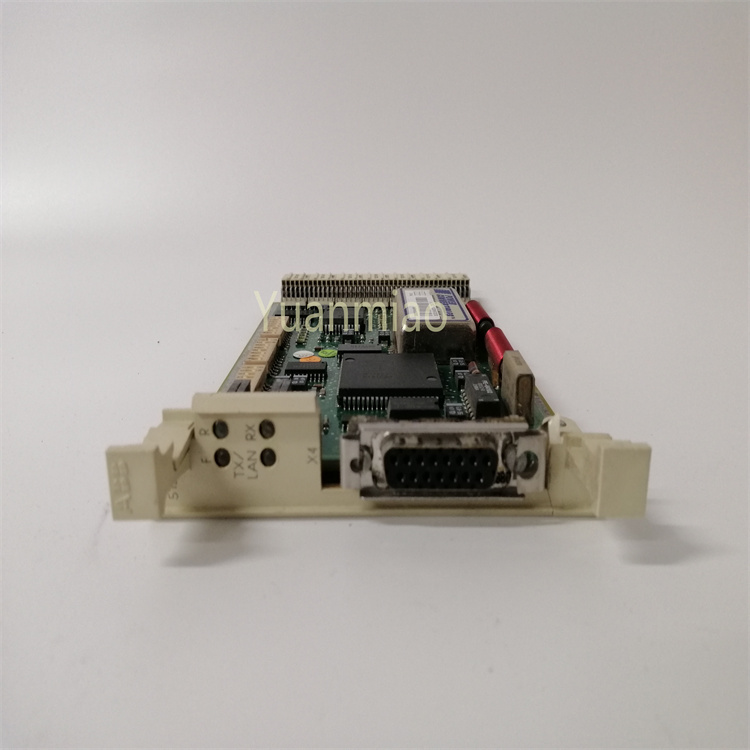

GE IC693CPU372-AE

GE IC693CPU372-AE is the core processing unit of the GE Fanuc 90-30 series programmable logic controller (PLC), designed specifically for medium and large-scale automation control systems. As the core of the system, this CPU module is responsible for executing user programs, processing I/O data, managing communication tasks, and coordinating the work of other modules in the system. Its high-performance processor and rich memory configuration enable it to handle complex industrial control applications, and it is widely used in manufacturing automation, process control, energy management, and other fields.

- CPU Type: High-performance 32-bit microprocessor

- Processing Speed: Execution time of basic logic instructions is less than 0.1μs/instruction

- Program Scan Cycle: Typical value is less than 1ms (depending on program complexity)

- Data Processing Capability: Supports integer and floating-point operations, and can handle complex mathematical algorithms

- User Program Memory: 2MB flash memory (expandable to 4MB)

- Data Memory: 2MB SRAM (with battery backup)

- Maximum I/O Image Table: 8192 points (digital) + 1024 words (analog)

- System Memory: 512KB (for operating system and system variables)

- Local I/O Expansion: Supports up to 16 I/O modules (connected via backplane bus)

- Remote I/O Connection: Supports connection to remote I/O stations via DH+, Genius, or Ethernet

- Maximum I/O Points: 65,536 digital points, 8,192 analog points

- Built-in Communication Ports:

- 1 RS-232 port (for programming and debugging)

- 1 DH+ port (for DeviceNet or DH+ network)

- 1 Ethernet port (10/100Mbps adaptive, supporting protocols such as Modbus TCP)

- Expanded Communication Options: Interfaces such as Profibus and CANopen can be expanded through communication modules

- Operating Voltage: 24VDC (±15%)

- Power Consumption: Typical value 10W, maximum value 15W

- Backup Battery: Built-in lithium battery, supporting data backup for up to 200 days (typical value)

- Temperature Range: 0°C to 60°C (operating temperature)

- Humidity Range: 5% to 95% (non-condensing)

- Vibration Resistance: Complies with IEC 60068-2-6 standard (10-57Hz, 1g)

- Shock Resistance: Complies with IEC 60068-2-27 standard (11ms, 15g)

- EMC Compatibility: Complies with EN 61131-2 standard, suitable for industrial environments

- Dimensions: 177.8mm × 101.6mm × 114.3mm (height × width × depth)

- Weight: Approximately 1.2kg

- Installation Method: Standard DIN rail mounting or panel mounting

- LED Indicators: Power, operating status, communication status, fault indication

- Adopts a high-speed 32-bit processor, capable of quickly executing complex control algorithms and logical judgments

- Supports multi-task processing, allowing multiple independent control programs to run simultaneously

- Equipped with floating-point arithmetic capability, suitable for application scenarios requiring precise calculations

- Supports five programming languages of the IEC 61131-3 standard:

- Ladder Diagram (LAD)

- Function Block Diagram (FBD)

- Structured Text (ST)

- Instruction List (IL)

- Sequential Function Chart (SFC)

- Provides an intuitive programming environment, supporting offline programming and online modification

- Built-in multiple communication interfaces, supporting multiple communication protocols such as industrial Ethernet and fieldbus

- Supports seamless integration with other PLCs, HMIs, and SCADA systems

- Provides remote programming and monitoring functions, facilitating system maintenance and fault diagnosis

- Uses industrial-grade components to ensure stable operation in harsh environments

- Built-in self-diagnostic function, real-time monitoring of CPU status and system faults

- Supports hot-swappable modules, facilitating system maintenance and upgrades

- Provides redundant power supply options to improve system reliability

- Supports expansion of multiple I/O modules, including digital, analog, and special function modules

- Can expand remote I/O and third-party device connections through communication modules

- Supports distributed control system architecture, adapting to application requirements of different scales

- It is recommended to use GE Fanuc Proficy Machine Edition programming software

- Supports Windows 7/8/10 operating systems

- Provides complete programming, debugging, and diagnostic tools

// Example: Typical system configuration of IC693CPU372-AE

// 1. Local I/O configuration

IC693MDL655 // 16-point digital input module

IC693MDL665 // 16-point digital output module

IC693ALG223D // 8-channel analog input module

IC693PWR321 // Power supply module

// 2. Communication configuration

IC693CMM321 // Communication module (supports Modbus RTU)

IC693ETH322 // Ethernet communication module

// 3. Programming example (ladder diagram logic)

NETWORK 1: Start/Stop Control

LD I:0/0 // Start button

O O:0/0 // Output hold

AN I:0/1 // Stop button

OUT O:0/0 // Control output

NETWORK 2: Temperature Monitoring

MOV AI:1/0 N7:0 // Read temperature value

CMP N7:0 50 // Compare with set value

JGE OVER_TEMP // Jump if greater than or equal to 50°C

OUT O:0/1 // Normal temperature indication

OVER_TEMP:

OUT O:0/2 // Over-temperature alarm

- Create a new project in the programming software

- Configure CPU module parameters (model, memory allocation, etc.)

- Add I/O modules and communication modules

- Set communication parameters (IP address, baud rate, protocol, etc.)

- Write communication programs (such as Modbus TCP master/slave)

- Download the program to the CPU and perform debugging

| Fault Phenomenon | Possible Causes | Solutions |

|---|

| CPU does not start | Power failure, program damage | Check power connections, replace the battery, re-download the program |

| Communication interruption | Network configuration error, cable failure | Check IP address settings, replace communication cables, check network interfaces |

| I/O module unresponsive | Module failure, loose wiring | Check module status LEDs, re-plug the module, check wiring |

| Abnormal program operation | Memory overflow, logic error | Optimize program structure, increase memory, check program logic |

| Frequent system alarms | Sensor failure, incorrect parameter settings | Check sensor inputs, adjust parameter settings, clear alarm records |

![]()