Description

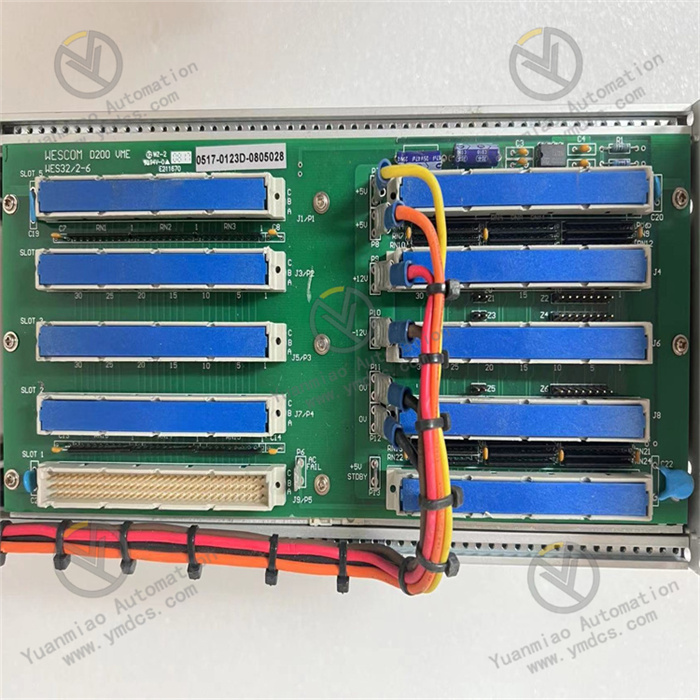

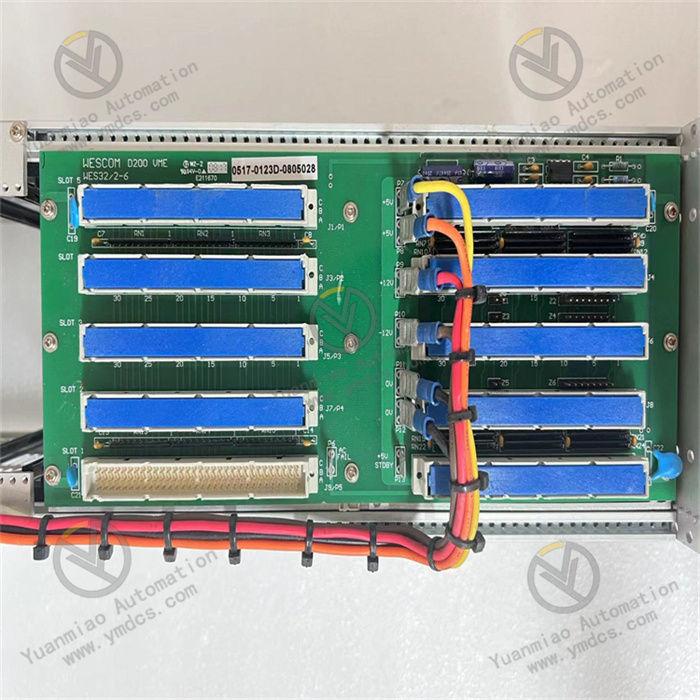

GE WESCOM D200 VME

Overview

GE WESCOM D200 VME is a high-performance industrial control platform based on the VME bus architecture, belonging to the GE WESCOM series of automation products. It is mainly applied to core control and data processing in large-scale industrial control systems. As a classic product of GE in the field of industrial automation, it integrates powerful computing capability, flexible expandability, and high-reliability design. It can realize real-time monitoring, logical control, and data interaction of complex industrial processes, serving as a key hub connecting on-site equipment and upper-level management systems.

With the advantages of high bandwidth and real-time performance of the VME bus, this platform can be adapted to various functional modules (such as I/O modules, communication modules, and processor modules). It is widely used in industries with high requirements for control system stability and real-time performance, such as electric power, metallurgy, and rail transit, providing solid technical support for the efficient operation and safety management of industrial production.

Technical Parameters

- Processor Configuration: Equipped with a 32-bit PowerPC series processor with a main frequency of up to 266MHz. It supports multi-tasking real-time operating systems (such as VRTX) and has data processing capability at the level of millions of instructions per second (MIPS), enabling efficient operation of complex control algorithms.

- Memory and Storage: Standard configuration includes 64MB SDRAM running memory, which can be expanded to 256MB; built-in 1GB flash memory for program storage and data backup, supporting power-off data protection to ensure that key configurations and operation records are not lost.

- VME Bus Characteristics: Complies with the VMEbus Rev. C.1 standard, with optional bus widths of 32 bits/64 bits. The maximum data transmission rate reaches 80MB/s, supporting parallel operation of multiple master devices, meeting the high-speed data exchange requirements of high-real-time control scenarios.

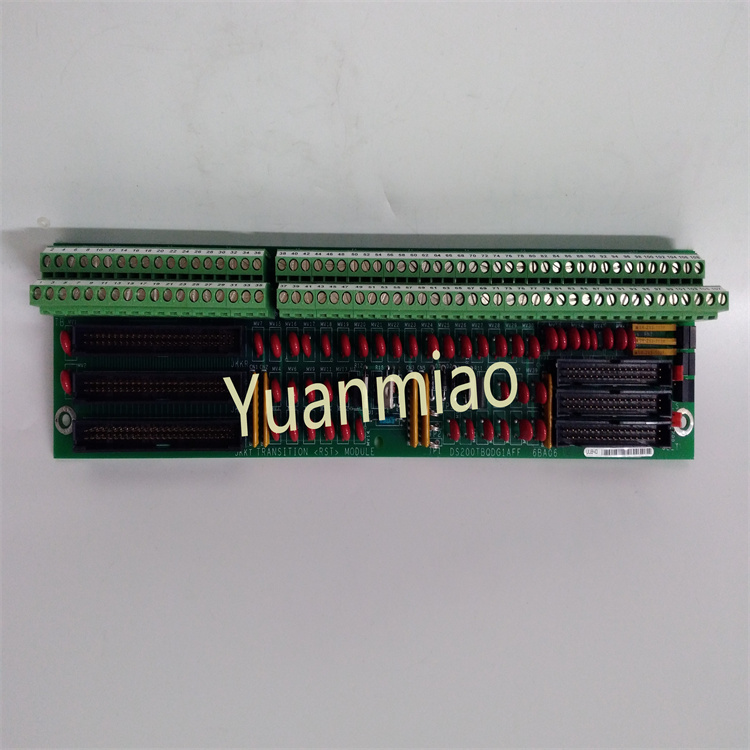

- I/O Expansion Capability: Supports up to 16 VME bus expansion slots, compatible with GE WESCOM series digital I/O modules, analog I/O modules, high-speed counting modules, etc. It can be expanded to a maximum of 1024 digital inputs/outputs and 256 analog inputs/outputs.

- Communication Interfaces: Equipped with 2 10/100Mbps Ethernet interfaces (supporting TCP/IP, Modbus TCP/IP), 4 RS-485 interfaces (supporting Modbus RTU), and 1 V.24/RS-232 interface, enabling seamless communication with on-site equipment, SCADA systems, and third-party control systems.

- Environmental Adaptability: Operating temperature range is 0℃-+60℃, storage temperature range is -40℃-+85℃; relative humidity is 5%-95% (non-condensing); vibration resistance reaches 10-500Hz, 1g acceleration, meeting the harsh environmental requirements of industrial sites.

- Physical Specifications: Adopts 19-inch rack-mounted installation, with a standard 3U/6U VME chassis structure. The size is approximately 483mm×177mm×300mm (width × height × depth) depending on the configuration, with a weight of about 8-12kg, supporting redundant power supply configuration.

- Certification Standards: Complies with international standards such as IEC 61131-2, UL 508, and CE, and has SIL 2 safety certification, suitable for industrial scenarios with high safety requirements.

Functional Features

- High-performance Real-time Control: Based on the PowerPC processor and VRTX real-time operating system, it can realize microsecond-level task scheduling and data processing, supporting the parallel operation of complex control algorithms (such as PID regulation, logical interlocking), meeting the strict real-time requirements of large-scale industrial processes.

- Flexible Module Expansion: The open architecture of the VME bus supports plug-and-play of various functional modules. Users can flexibly configure the number of I/O points, communication interface types, and processing capabilities according to control needs without reconstructing the system core, greatly reducing the expansion cost.

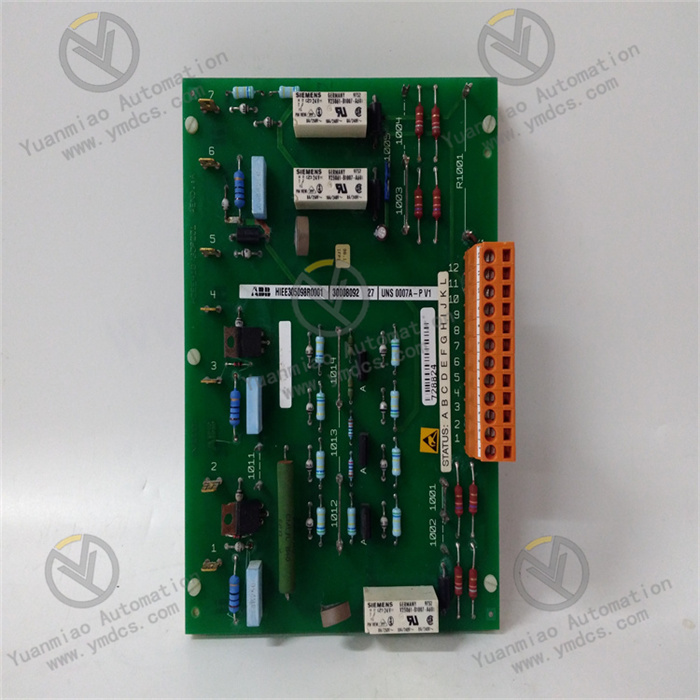

- High-reliability Design: Supports redundant configuration of power supplies, processors, and communication interfaces. When a component fails, it can automatically switch to the standby unit with a switching time ≤50ms, ensuring uninterrupted operation of the control system; at the same time, electrical isolation design is adopted between modules, with strong anti-electromagnetic interference capability, suitable for industrial environments with strong interference.

- Powerful Data Integration Capability: Through multi-protocol communication interfaces, it can centrally collect data from distributed on-site equipment (such as sensors, actuators, intelligent instruments) and support data interaction with upper-level systems such as SCADA and MES, realizing full-process data connection from bottom-level control to upper-level management.

- Standardized Programming Environment: Supports IEC 61131-3 standard programming languages (ladder diagram, function block diagram, structured text, etc.), and is equipped with configuration software such as GE CIMPLICITY, facilitating engineers to quickly develop, debug, and maintain control programs, shortening the project implementation cycle.

- Comprehensive Diagnosis and Maintenance: Built-in intelligent diagnosis function, which can real-time monitor module operation status, communication link quality, and power supply health. Fault information is prompted through both indicator lights and system logs, supporting remote diagnosis and online maintenance, reducing on-site maintenance workload.