Description

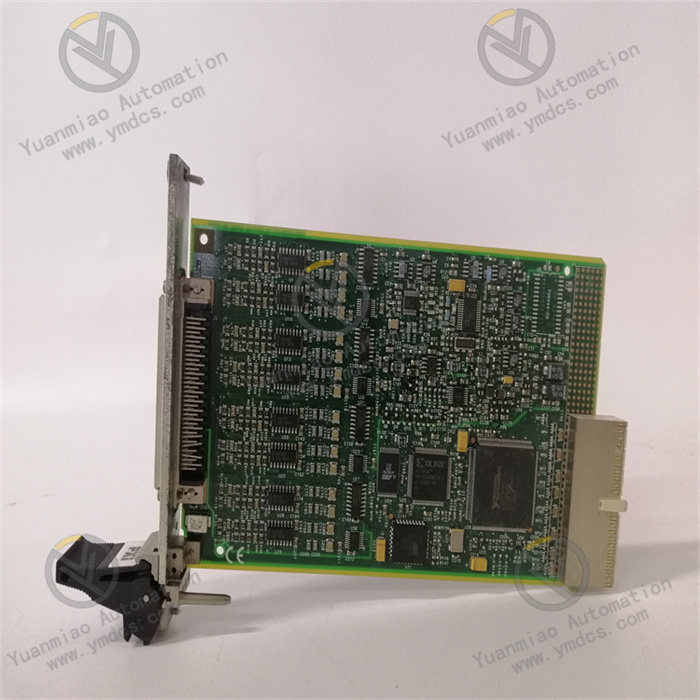

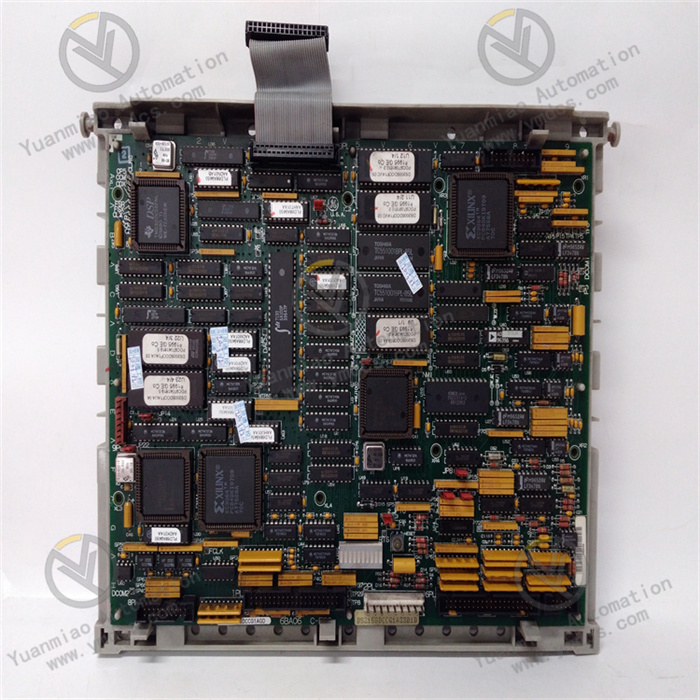

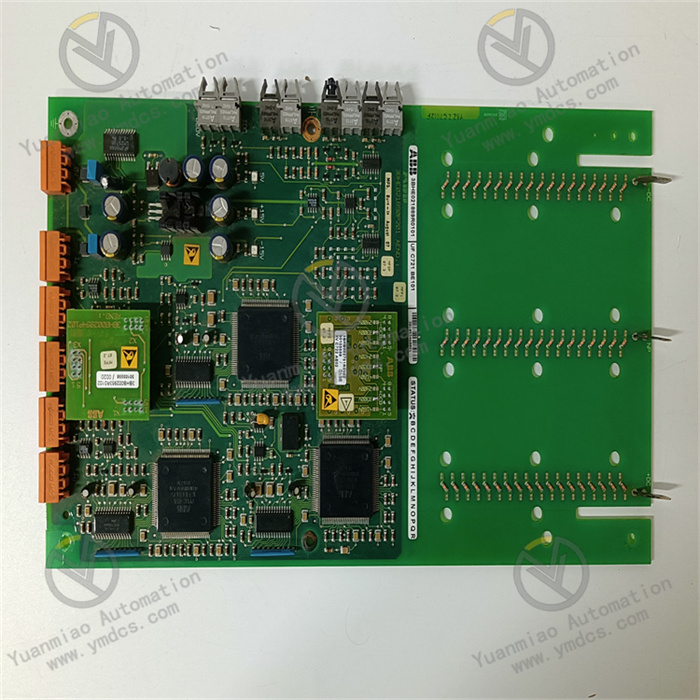

ABB PM861K01 3BSE018105R1 is a processor unit kit of ABB, belonging to the AC 800M series, mainly used in industrial automation control systems. Hardware Composition: PM861 CPU: It is the core processing component, responsible for executing control algorithms, processing data, and coordinating the operation of the system. TP830 Baseboard: It provides electrical connections and physical support for other components, with a width of 115mm. TB850 CEX - Bus Terminator, TB807 Module Bus Terminator, TB852 RCU - Link Terminator: They are used for the terminal matching of the bus to ensure the stability and integrity of signal transmission. Battery for Memory Backup: The model is 4943013 - 6, which protects important data and programs from being lost when the system power is cut off. 4 - Pin Power Plug: The part number is 3BSC840088R4, which provides power connection for the module.

Functional Characteristics: High-Performance Control: It has strong computing power and data processing capabilities, can implement complex control algorithms, and can quickly respond to various events and requests in the system to ensure the precise control of industrial processes. CPU Redundancy Support: It supports CPU redundancy configuration, improving the reliability and availability of the system. When the main CPU fails, the standby CPU can automatically take over the work to ensure the uninterrupted operation of the system. Integration and Openness: It can be closely integrated with ABB's 800xA system, and can also communicate and interact with other third-party systems. It has good openness and compatibility, making it convenient for users to build complex industrial automation systems. Technical Parameters: Dimensions: The depth is 20.3cm, the height is 15.7cm, and the width is 13.5cm. Weight: 1.14kg. Operating Voltage: Usually 220V. Output Frequency: Up to 60KHz. Application Scenarios: Industrial Automation Production Lines: In the production line control of industries such as automobile manufacturing and electronic device production, it can monitor and control various parameters in the production process in real time to ensure the stability of production and the quality of products. Process Control Systems: In process industries such as petroleum, chemical industry, and power industry, it is used for precise control of technological processes, and realizes the adjustment and optimization of parameters such as temperature, pressure, and flow. Intelligent Building Systems: It can be applied to the heating, ventilation, and air conditioning systems, lighting systems, elevator control systems, etc. of intelligent buildings to achieve the automated management and energy-saving operation of buildings.

Common Faults and Solutions:

Communication Fault: The fault phenomenon is the interruption of communication or data transmission errors between the module and other devices. The reasons may include poor connection of communication cables, incorrect communication parameter settings, and faults in the module communication interface, etc. The solution is to check whether the communication cable is firmly connected and whether there is any damage; confirm whether the communication parameter settings match those of other devices; if there is a fault in the communication interface, professional personnel should be contacted to repair or replace the module.

Processor Fault: It is manifested as abnormal operation of the module, the appearance of error codes, or system crashes. It may be caused by reasons such as overheating, power supply faults, software errors, or hardware damage. When solving the problem, check the heat dissipation situation of the module to ensure good ventilation in the installation environment; measure whether the power supply voltage is stable within the rated range; try to reset the module or update the software; if the hardware is damaged, replace the module.

Memory Fault: Such as data loss, program operation errors, etc. It may be caused by reasons such as insufficient battery power of the memory or damage to the memory chip. First, replace the memory backup battery. If the problem still exists, it may be necessary to replace the memory chip of the module or the entire module.

I/O Connection Fault: When there are problems with the connection to I/O devices, it will lead to the inability to correctly read input signals or control output devices. The reasons include poor connection of I/O cables, faults in I/O modules, incorrect I/O address configuration, etc. The solution is to check the connection of I/O cables; confirm whether the I/O address configuration is correct; if there is a fault in the I/O module, try to replace the module.