Description

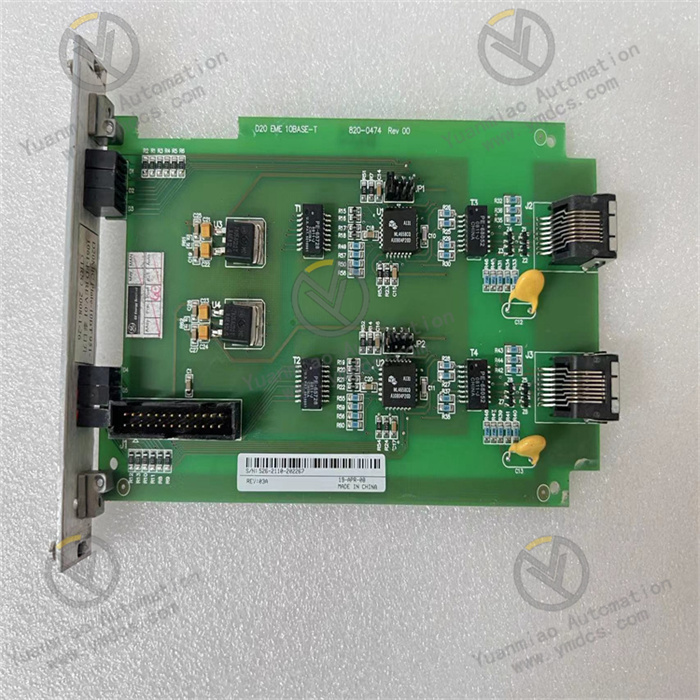

GE D20 EME 10BASE-T

Overview

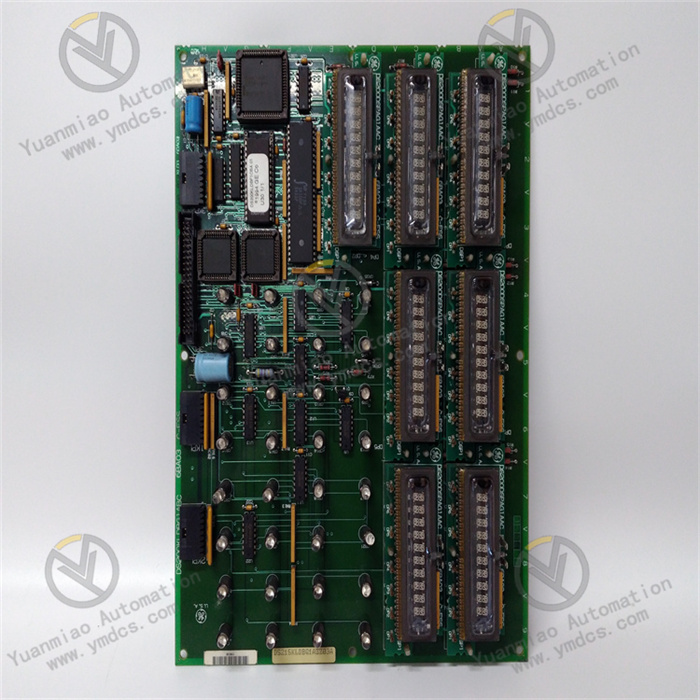

GE D20 EME 10BASE-T is a compact embedded control module with enhanced network communication functions in the GE WESDAC D20 series, designed specifically for small and medium-sized industrial control systems that require basic Ethernet connectivity. On the basis of retaining the core control functions of GE D20 EME, it focuses on enhancing the stability and compatibility of the 10BASE-T Ethernet interface. It is mainly used to realize networked data interaction between industrial equipment and upper computers or monitoring systems, while undertaking basic tasks such as logical control and signal acquisition.

As a control unit for small and medium-sized scenarios, the module integrates control and communication functions with a compact design. It can not only independently complete the local control of equipment but also access the industrial local area network through Ethernet to realize remote upload of data and reception of instructions. It provides a convenient solution for networked monitoring of small and medium-sized production lines and equipment control cabinets, and is an important node connecting underlying equipment and industrial networks.

Technical Parameters

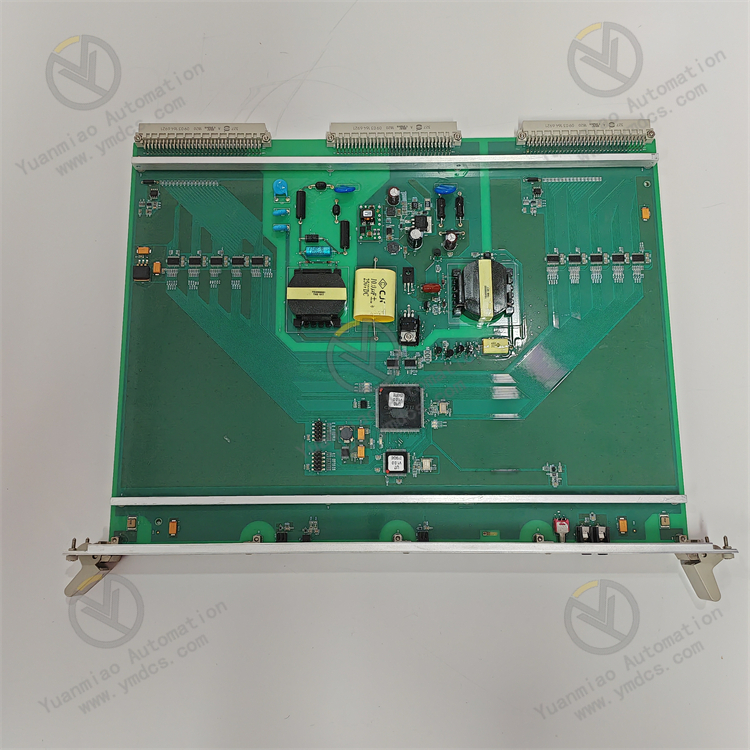

- Power Parameters: The working power supply is 24V DC, with an allowable voltage fluctuation range of ±15% and a rated power consumption of ≤18W. It can be directly connected to the industrial DC power supply system and adapt to voltage fluctuation environments.

- Processor and Memory: Equipped with a 16-bit microprocessor with a main frequency of 80MHz, 8MB Flash memory, and 2MB RAM. It supports storing more than 1000 control logic instructions, meeting the computing needs of small and medium-sized control scenarios.

- I/O Interfaces: Includes 16 digital inputs (24V DC, compatible with dry/wet contacts), 8 digital outputs (transistor output, maximum current 1A), and 4 analog inputs (0-10V DC or 4-20mA). Basic signal acquisition and control can be completed without expanding modules.

- Communication Interfaces: Equipped with 1 10BASE-T Ethernet interface (compliant with IEEE 802.3 standard), supporting TCP/IP protocol stack and Modbus TCP/IP protocol; 1 RS-485 interface (supporting Modbus RTU protocol), with a communication rate adjustable between 9600bps and 115200bps.

- Network Performance: The maximum transmission rate of the Ethernet interface is 10Mbps, supporting full-duplex/half-duplex mode and automatic negotiation function; the network transmission distance is ≤100 meters (using category 5 or above twisted-pair cables), meeting the wiring needs of industrial on-site local area networks.

- Environmental Adaptability: The operating temperature range is -10℃-+60℃, and the storage temperature range is -40℃-+85℃; the relative humidity is 5%-95% (non-condensing); the protection level is IP20, suitable for installation in control cabinets to resist dust and slight moisture.

- Physical Specifications: The size is approximately 100mm×80mm×65mm (length × width × height), and the weight is about 220g. It supports DIN rail mounting, saving installation space.

- Certification Standards: Complies with CE and UL 508 standards, and has passed industrial electromagnetic compatibility (EMC) testing and IEEE 802.3 Ethernet standard certification, ensuring the stability and security of network communication.

Functional Features

- Enhanced Ethernet Communication: Integrates a 10BASE-T Ethernet interface, supports Modbus TCP/IP protocol, and can be directly connected to industrial Ethernet to realize high-speed data interaction with upper computers and SCADA systems. Compared with traditional serial communication, it improves data transmission rate and network coverage, suitable for small and medium-sized industrial scenarios that require remote monitoring.

- Integration of Control and Communication: On the basis of retaining the compact integrated design, it deeply integrates logical control and network communication functions. Without additional configuration of an Ethernet gateway, it can realize the dual functions of "control + networking", simplifying the system architecture and reducing integration costs.

- Stable Network Connection: The Ethernet interface has an anti-interference design, supports data frame verification and retransmission mechanisms, and can maintain stable communication in the electromagnetic interference environment of industrial sites; the automatic negotiation function can adapt to different network devices (such as switches, routers), reducing the difficulty of network configuration.

- Real-time Data Interaction: The 10Mbps network transmission rate combined with a control cycle of ≤10ms can realize the real-time transmission of control instructions and monitoring data. For example, in remote monitoring scenarios, the upper computer can timely obtain the equipment operation status and issue adjustment instructions, ensuring the timeliness of control.

- Flexible Compatibility and Expansion: In addition to Ethernet, the RS-485 interface is retained to support the Modbus RTU protocol, which can connect serial devices and network devices at the same time, adapting to the industrial environment with a mixture of old and new systems; it supports collaborative work with other modules of the GE D20 series, facilitating the expansion of I/O points or communication methods according to needs.

- Simple Network Configuration: Network parameters such as IP address and subnet mask can be intuitively configured through dedicated configuration software, supporting DHCP to automatically obtain IP, simplifying the network deployment process; the module has a built-in network diagnosis function, and the link status can be viewed through indicators or software, facilitating quick troubleshooting of network faults.

Application Fields

- Remote Monitoring of Small and Medium-sized Equipment: In small injection molding machines, packaging machines and other equipment, the operating parameters of the equipment (such as temperature, pressure, output) are uploaded to the remote monitoring platform through 10BASE-T Ethernet. Managers can view the equipment status in real-time in the office and issue start-stop instructions remotely, reducing the workload of on-site inspections.

- Networking of Distributed Production Lines: In distributed production lines such as electronic component assembly and medical device assembly, multiple GE D20 EME 10BASE-T modules are connected to the central control cabinet through Ethernet to realize collaborative control and data aggregation of equipment at each workstation. For example, coordinating the actions of manipulators at different workstations to ensure consistent production rhythms.

- Intelligent Building Equipment Control: In the lighting and air conditioning zone control of commercial buildings, the module is connected to the building management system through Ethernet to collect temperature and light signals in each area, remotely control lamp switches and air conditioning wind speed, realize networked management of building equipment, and improve energy utilization efficiency.

- Monitoring of Small Municipal Pumping Stations: In secondary water supply pumping stations and small sewage treatment pumping stations in urban communities, data such as pump operation status and pipeline pressure are transmitted to the municipal monitoring center through Ethernet. The center can remotely adjust the pump frequency or switch the operation mode to ensure stable water supply/drainage.

- Automation of Laboratory Equipment: In small reaction devices and testing equipment in industrial laboratories, the module communicates with the experimental management system through Ethernet, uploads experimental parameters (such as reaction temperature, reagent dosage) in real-time, and receives experimental step instructions issued by the system, realizing the automation and data traceability of the experimental process.