Description

Functional Features

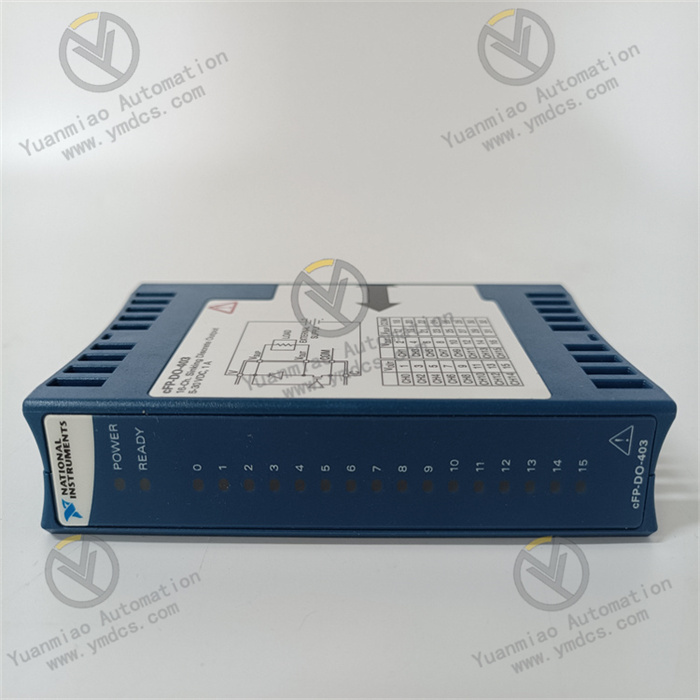

Multi-channel Input: It has 8 isolated analog input channels, which can be connected to multiple analog sensors or field devices simultaneously, enabling synchronous monitoring of multiple physical quantities.

Rich Input Types: It supports various analog input types, including 4 - 20mA current signals, 0 - 10V voltage signals, and resistance temperature detector (RTD) signals, meeting the needs of different types of sensors and measurements.

High Precision and High Resolution: With an accuracy of ±0.1% full scale and a resolution of 0.001% full scale, it can accurately measure and convert the input analog signals, providing accurate data for the control system.

Fast Signal Processing: The signal processing time is less than 10ms, which can promptly collect, convert, and process the input signals, ensuring the system's rapid response to on-site changes.

Fault Detection and Isolation: It has a fault detection and isolation mechanism, which can automatically detect faults in the input channels and isolate the faulty channels from the system, preventing the faults from affecting the operation of the entire system and improving the reliability and stability of the system.

Configurable Scaling and Filtering: It provides configurable signal scaling and filtering options. Users can perform processing such as linear scaling and filtering on the input signals according to actual needs to meet different control strategies and process requirements.

Technical Parameters Number of Channels: 8. Input Types: 4 - 20mA, 0 - 10V, RTD. Accuracy: ±0.1% full scale. Resolution: 0.001% full scale. Input Impedance: 250kΩ. Common-mode Rejection Ratio: 60dB. Signal Processing Time: <10ms. Operating Temperature: -40°C to 70°C. Power Consumption: 10W. Application Scenarios Process Control: Suitable for industries such as manufacturing and chemical industry, it is used to monitor and control process parameters such as temperature, pressure, and flow rate, achieving precise control and optimization of the production process. Machine Control: It can be connected to sensors and actuators in machinery to achieve precise control and automated operation of mechanical equipment, improving production efficiency and product quality. Building Automation: Integrated with heating, ventilation, and air conditioning (HVAC) systems and environmental sensors, it is used to monitor and control environmental parameters such as temperature, humidity, and air quality inside buildings, realizing energy-saving and comfortable building environment management. Environmental Monitoring: In environmental monitoring systems, it can be used to monitor environmental parameters such as air quality and water quality, providing data support for environmental protection and monitoring.

Application Cases: Power Industry Boiler Control: In a power plant, this module can be used to collect various analog signals during the boiler operation, such as temperature, pressure, and water level. By converting these analog signals into digital data and transmitting them to the control system for analysis and processing, it can achieve precise control of key aspects such as boiler combustion and water level adjustment, ensuring the safe and stable operation of the boiler and improving power generation efficiency. Turbine Control: Connected to the relevant sensors of the steam turbine, it monitors parameters such as the rotation speed, vibration, and steam pressure of the steam turbine. According to these real-time data, the control system can adjust the steam inlet amount, speed regulation system, etc. of the steam turbine to ensure that the operation state of the steam turbine is always at the optimal level, reducing the possibility of faults and improving the reliability of power production. Generator Control: It is used to monitor the operation parameters of the generator, such as voltage, current, frequency, and temperature. Through the precise measurement and analysis of these parameters, it can achieve functions such as excitation regulation and power control of the generator, ensuring that the generator outputs stable electrical energy to meet the needs of the power grid. Chemical Industry Process Control: In the chemical production process, this module can collect parameters such as the temperature, pressure, and flow rate of the reactor, as well as the composition information of various materials. Based on these data, the control system can adjust the reaction conditions in real time, such as the amount of reactants added, reaction temperature, and pressure, to ensure the smooth progress of chemical reactions, improve product quality and output, and ensure the safety of the production process at the same time. Distillation Column Control: Connected to the sensors of temperature, pressure, liquid level, etc. of the distillation column, it monitors the operation status of the distillation column in real time. Through the analysis of these parameters, the control system can adjust the operation parameters such as the reflux ratio and heating amount of the distillation column, achieving precise control of the distillation process, making the product reach the required purity standard, and reducing energy consumption and production costs. Steel Industry Blast Furnace Monitoring: It is used to collect parameters such as the temperature, pressure, and gas permeability of the blast furnace, as well as the composition information of raw materials and hot metal. Through the analysis of these data, operators can promptly understand the operation status of the blast furnace, adjust parameters such as the burden ratio and blast volume to ensure the stable operation of the blast furnace and improve the output and quality of hot metal. Rolling Mill Control: Connected to the sensors of speed, pressure, position, etc. of the rolling mill, it monitors various parameters during the rolling process in real time. According to these data, the control system can precisely control parameters such as the rolling speed and reduction amount of the rolling mill, ensuring the dimensional accuracy and surface quality of the steel products, and improving production efficiency and product quality.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

Emerson/Ovation Related Products

| 1C31116G04 | 5X00058G01 |

| 1C31122G01 | 5X00059G01 |

| 1C31125G02 | 5X00062G01 |

| 1C31127G01 | 5X00070G01 |

| 1C31132G01 | 5X00070G03 |

| 1C31223G01 | 5X00105G01 |

| 1C31107G01 | 5X00105G14 |

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.