Description

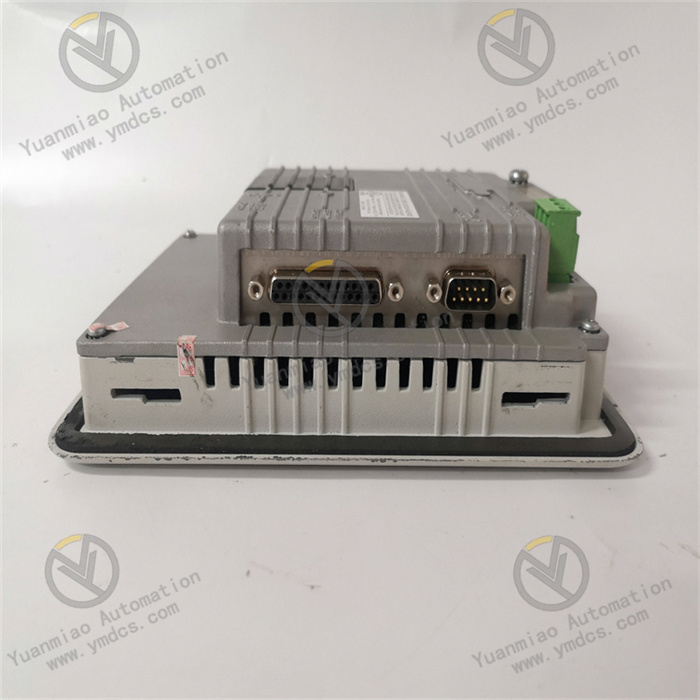

ABB PP825 3BSE042240R1

The ABB PP825 3BSE042240R1 is a high-performance industrial touchscreen panel with the following core features:

I. Outstanding Operational and Display Performance

Clear and Intuitive Display

- Equipped with a 12-inch color TFT display with a resolution of 800×600 pixels, offering vibrant colors and sharp imagery. It supports clear viewing from multiple angles, making it suitable for real-time data monitoring and operational interface display in industrial environments.

Sensitive Resistive Touchscreen

- Utilizes resistive touch technology with single-point touch support, ensuring responsive operation. It remains stable even when used with gloves or in slightly oily/dusty environments, adapting to the complex operational demands of industrial sites.

II. High Reliability and Environmental Adaptability

Wide Temperature Range

- Operating temperature: 0°C–55°C; storage temperature: -20°C–70°C. It ensures stable operation in high/low-temperature or large-temperature-gradient industrial environments without additional temperature control equipment.

Anti-Interference and Durability

- Constructed with industrial-grade materials and design, featuring vibration and impact resistance, and complying with strict industrial standards (e.g., electromagnetic interference resistance). Suitable for high-interference scenarios such as machine tools and production lines.

Dust and Moisture Resistance

- Supports up to 85% relative humidity (non-condensing), making it capable of withstanding harsh conditions like humidity and dust, thus extending equipment service life.

III. Flexible Communication and Integration Capabilities

Multiple Communication Interfaces

- Supports interfaces such as Ethernet, RS-232/RS-485, and is compatible with mainstream industrial communication protocols like Modbus, Profibus, and EtherNet/IP. It enables seamless connectivity with devices such as PLCs, drives, and sensors for real-time data interaction.

Open Software Compatibility

- Supports ABB’s self-developed configuration software like Panel Builder 300, allowing users to customize interface layouts, function buttons, and data display logic to flexibly adapt to operational requirements of different control systems.

IV. Convenient Installation and Maintenance

Compact Mechanical Design

- Dimensions: 368mm×289mm×92mm; Weight: 6.3kg. Supports panel or bracket mounting, saving space and facilitating integration into control cabinets or operator stations.

Maintenance-Free Design

- Fanless structure reduces dust ingress and mechanical failure points. Supports remote diagnostics and firmware upgrades to lower maintenance costs. Equipped with LED status indicators for quick identification of operational anomalies (e.g., power or communication faults).

V. Industrial-Grade Safety and Stability

Redundant Power Supply Design

- Supports dual-power input (e.g., 24V DC redundant power supply) to ensure continuous operation during power fluctuations or failures, preventing production interruptions due to power outages.

Data Security Protection

- Supports user permission management (e.g., multi-level password protection) to prevent unauthorized operations. Built-in memory stores historical data and alarm information for easy traceability and fault analysis.

Working Principle

Scanning Operation Mode

Similar to most PLCs, the PP825 employs a "sequential scanning, continuous cycling" mode. During operation, its CPU periodically scans user programs stored in memory according to instruction sequence numbers. Without jump instructions, it executes user programs line by line from the first instruction to the end, then returns to the first instruction for the next scan.

Specific Scanning Phases

Each scan cycle of the PP825 includes three mandatory phases: input sampling, program execution, and output refresh.

- Input Sampling: Reads the on/off statuses or input data of all input terminals temporarily stored in the input latch in scanning order and writes them into corresponding input status registers. The input port is then closed, and the program execution phase begins.

- Program Execution: Scans and executes each instruction in the order of user program storage. After corresponding calculations and processing, results are written into output status registers.

- Output Refresh: After all instructions are executed, the on/off statuses in the output status registers are sent to the output latch during this phase and output via a specific method to drive corresponding output devices.

Programming Software and Operation Methods for ABB PP825 3BSE042240R1

The ABB PP825 3BSE042240R1, as an industrial touchscreen, is primarily programmed and configured using Panel Builder 300 software. Below is a detailed introduction to this software and its operation methods:

Overview of Panel Builder 300 Software

Panel Builder 300 is a configuration software developed by ABB specifically for industrial touchscreens. Its main function is to create intuitive and feature-rich human-machine interfaces (HMIs). With this software, users can customize settings for screen layouts, interactive elements, data displays, and communication connections to meet specific needs in different industrial scenarios.

Software Functional Features

- Graphical Development Environment

- Features a drag-and-drop editor that simplifies interface design. Users can easily add common elements such as buttons, text boxes, indicator lights, and charts without writing complex code.

- Provides a rich library of pre-defined graphics, including numerous industrial-standard symbols and icons, to help users quickly build professional operational interfaces.

- Supports custom graphic imports, allowing users to add specific company logos or equipment images as needed to enhance interface personalization and recognition.

- Flexible Data Processing

- Enables real-time data exchange with ABB and third-party PLCs, supporting multiple communication protocols such as Modbus, Profibus, and Ethernet.

- Achieves data collection, display, recording, and analysis, facilitating comprehensive monitoring of production processes.

- Supports alarm management functions, promptly notifying relevant personnel when abnormal data is detected.

- Multi-Language Support

- Offers interfaces in multiple languages, allowing users to switch between languages easily to meet the needs of multinational enterprises or international projects.

- Enables the creation of different language versions for the same interface, accommodating operators with different language backgrounds.

- User Permission Management

- Supports multi-level user permission settings, where users at different levels have different operational authorities to ensure system security.

- Features password protection to prevent unauthorized access to the system.

- Simulation and Debugging Tools

- Provides a simulator function that allows users to perform simulation testing on interfaces during the development phase to check whether interface functions and interactions are normal.

- Supports real-time debugging, displaying data transmission statuses and variable values to help users quickly locate and resolve issues.

Operation Methods

- Software Installation and Project Creation

- First, install the Panel Builder 300 software on a computer. After installation, launch the software.

- Create a new project in the software and select the device model compatible with the PP825 touchscreen to ensure software-hardware compatibility.

- Interface Design

- Select required elements (e.g., buttons, indicator lights, text boxes) from the graphics library and drag them onto the design interface.

- Adjust the size, position, and properties (e.g., color, font, display format) of elements according to actual needs.

- Add interactive functions to elements, such as executing specific operations when a button is clicked or triggering animations when data changes.

- Data Connection Configuration

- Configure communication connections with PLCs or other data sources, select appropriate communication protocols, and set corresponding parameters.

- Associate interface elements with variables in the PLC to ensure data is displayed and updated in real time on the interface.

- Logical Programming

- Use the scripting language or logic editor provided by Panel Builder 300 to write interaction logic for interface elements.

- Set alarm conditions and handling methods so that the system can issue timely alerts when alarm conditions are met.

- Simulation and Testing

- Run the simulator in the software to perform simulation testing on the created interface and check whether its functions and interactions meet expectations.

- During simulation, use debugging tools to view data transmission statuses and variable values, identifying and resolving issues in a timely manner.

- Project Download and Deployment

- Download the tested project to the PP825 touchscreen via USB, Ethernet, or other methods.

- After downloading, launch the project on the touchscreen and conduct actual operation testing to ensure the system works normally in real-world environments.

Application Tips

- Optimize Interface Layout: Reasonably plan the interface layout by grouping related elements to improve operational efficiency. Use layered designs to organize interface elements of different functions into separate layers for easier user management.

- Improve Response Speed: Reduce unnecessary data refreshes and avoid frequent data transfers to enhance system responsiveness. Optimize communication configurations by selecting appropriate communication rates and protocols to ensure stable and efficient data transmission.

- Enhance User Experience: Use animations and transition effects to enhance the visual appeal and interactivity of interfaces. Provide operation guides and help information to facilitate quick familiarization with the system.

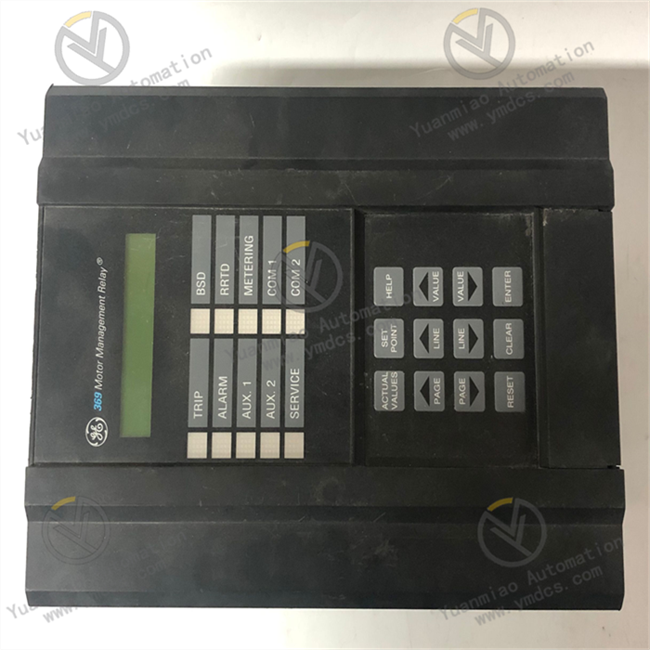

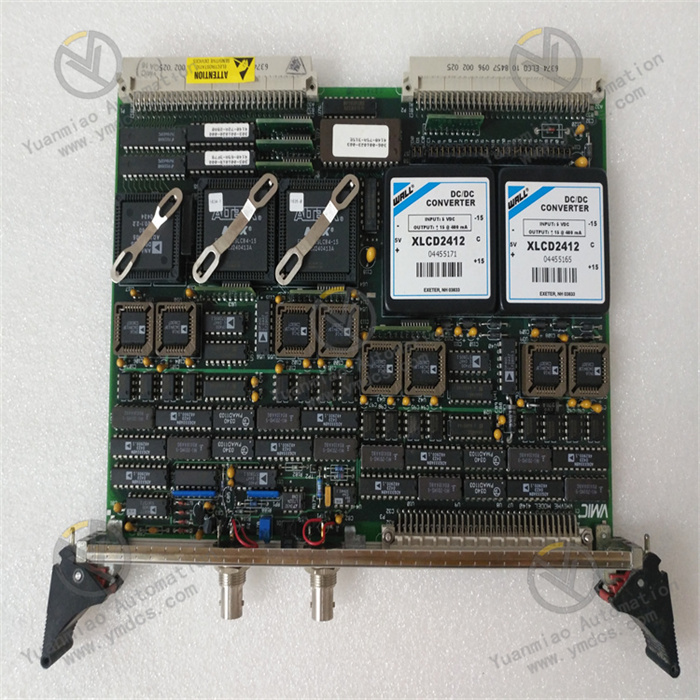

Other Brand-Related Products

Motorola MVME55006E-0163 | VMEbus Single-Board Computer

ENTERASYS A2H254-16 P0973BK Ethernet Switch

Foxboro FCP270 P0917YZ | Digital Output Module

Honeywell 8C-TDODA1 51307149-175 | Digital Output Module

Emerson PR6423/010-000-CN+CON021 Eddy Current Sensor