Description

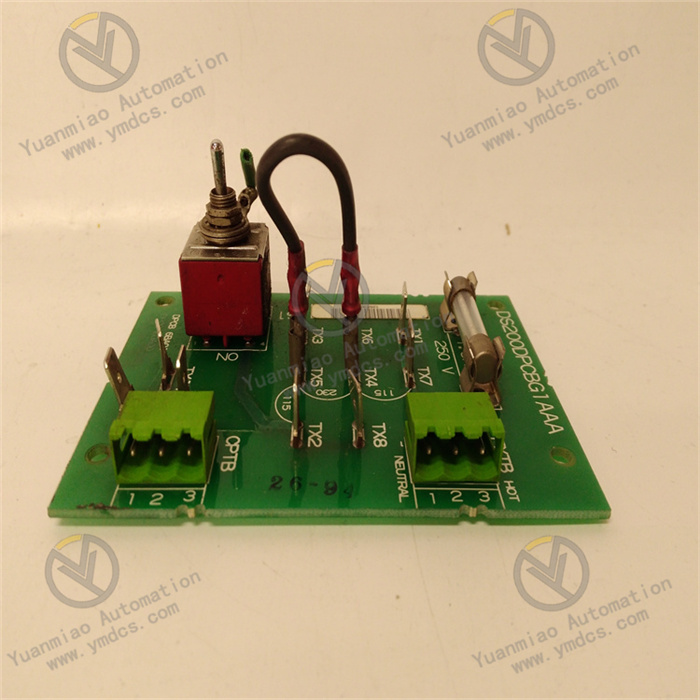

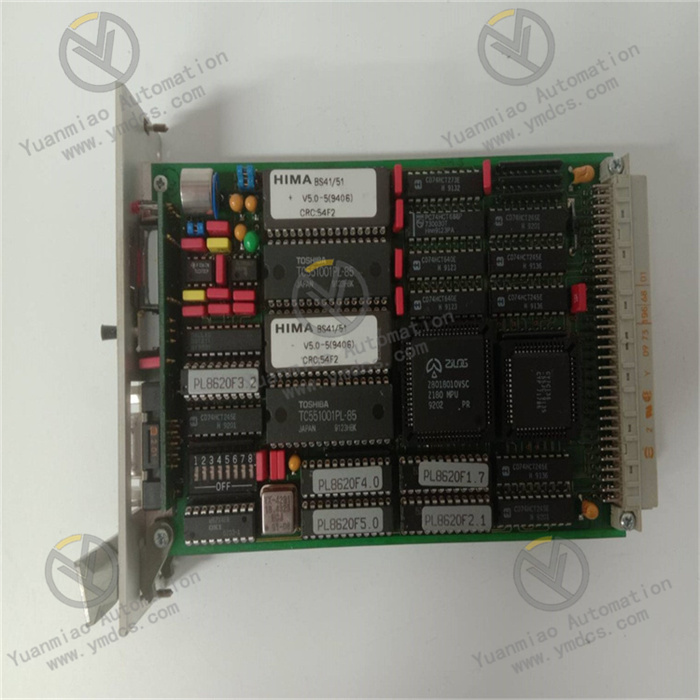

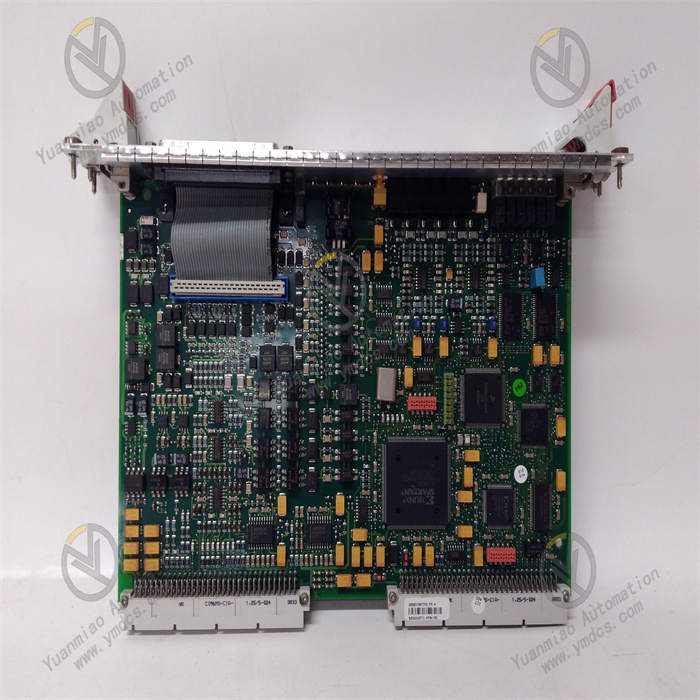

GE DS200ADPBG1ABB

Overview

The GE DS200ADPBG1ABB is a Genius adapter board meticulously crafted by General Electric (GE), holding a significant position in the field of industrial automation, especially in GE's Mark V series turbine control systems. As a key interface module in the system, it shoulders the important task of connecting and adapting various input/output (I/O) devices, committing to achieving stable and efficient communication and data exchange between the system and external devices, providing a solid guarantee for the smooth operation of industrial production processes.

Functional Features

Wide Device Adaptability

It has strong compatibility and can adapt to various types of I/O devices. Whether analog input devices such as temperature sensors and pressure sensors, or output devices such as motors and solenoid valves for control execution, it can easily interface with them, greatly enhancing the flexibility of system configuration and meeting the diversified control needs of different industrial scenarios.

Convenient Modular Design

Adopting the modular design concept, this design makes the installation process simpler. Maintenance personnel can also quickly locate and replace the corresponding modules during maintenance and troubleshooting, effectively shortening equipment downtime and improving the continuity and efficiency of industrial production.

Excellent Reliability

Manufactured with high-quality industrial-grade components, these components have undergone strict screening and testing, and can effectively cope with harsh conditions such as electromagnetic interference, mechanical vibration, and temperature changes commonly found in industrial environments, ensuring that the adapter board can operate stably for a long time in complex and harsh environments, providing strong support for the reliability of industrial production.

Flexible Customizability

Fully considering the personalized needs of different customers, it supports functional customization according to specific customer requirements. Customers can adjust and optimize the functions of the adapter board according to the characteristics of their own industrial processes, making it better fit the actual production needs and improve the overall production efficiency.

Perfect Signal Processing Function

It integrates a signal conditioning circuit, which can perform operations such as voltage adjustment, filtering, and amplification on input and output signals. Through these processes, the accuracy and reliability of signal transmission between devices are ensured, signal distortion and interference are reduced, and the precise transmission of system control commands and the accurate feedback of device status information are guaranteed.

Technical Parameters

| Parameter Category | Details |

|---|---|

| Product Model | DS200ADPBG1ABB |

| Product Type | Genius Adapter Board |

| Series | Mark V Series |

| Number of Slots | 4 |

| I/O Points | Up to 128 points |

| Communication Interfaces | RS-232, RS-485, CAN |

| Power Supply | 24V DC |

| Power Consumption | Approximately 5W |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% (non-condensing) |

| Vibration Resistance | 5G to 500Hz |

| Shock Resistance | 50G |

| Dimensions | Approximately 140mm×85mm×25mm |

| Weight | Approximately 250g |

| Protection Level | IP67 |

| Working Voltage | +5V DC (6A), 28V DC (power supply) |

| Installation Method | DIN Rail Mounting |

| Technical Process | Surface Mounting |

Application Fields

Power Energy Industry

In power plants, especially those using GE Mark V series turbine control systems, it is used to connect various sensors (such as temperature sensors, pressure sensors, speed sensors) with the control system. By real-time collecting various parameters in the turbine operation process and accurately conveying control commands to the actuators (such as regulating valves, oil pump motors), it ensures the efficient and stable operation of the turbine and improves power generation efficiency and power supply reliability.

Industrial Automation Production Lines

In automated production lines such as automobile manufacturing and electronic assembly, it is used to connect PLCs with various on-site I/O devices. For example, it connects sensors to detect material positions, equipment operation status and other information, and transmits the control commands issued by the PLC to execution devices such as mechanical arms and conveyor belt motors, realizing the automated operation of the production line and improving production efficiency and product quality.

Petrochemical Industry

In links such as oil extraction, oil refining, and chemical production, it adapts various field instruments (such as flowmeters, level gauges) to the control system. It accurately collects key parameters such as flow, level, and temperature in the production process and controls the operation of equipment such as pumps and valves, ensuring that the chemical production process is carried out in accordance with the 预定 technological requirements and guaranteeing production safety and product quality.

Intelligent Building Control Systems

It is used to connect various devices in intelligent buildings, such as intelligent switches and sensors in the lighting system, and controllers and actuators in the air conditioning system. Through data interaction, it realizes the intelligent control of the building's lighting, air conditioning, ventilation and other systems, improves energy use efficiency, and creates a comfortable and convenient environment for users.

Transportation Field

In transportation hubs such as ports and airports, it connects automated loading and unloading equipment (such as cranes, conveyor belts) with the control system. Through real-time communication, it coordinates the operation of equipment and improves cargo loading and unloading efficiency; in the railway system, it is used to connect signal control equipment with actuators to ensure the safe and smooth operation of trains.