Description

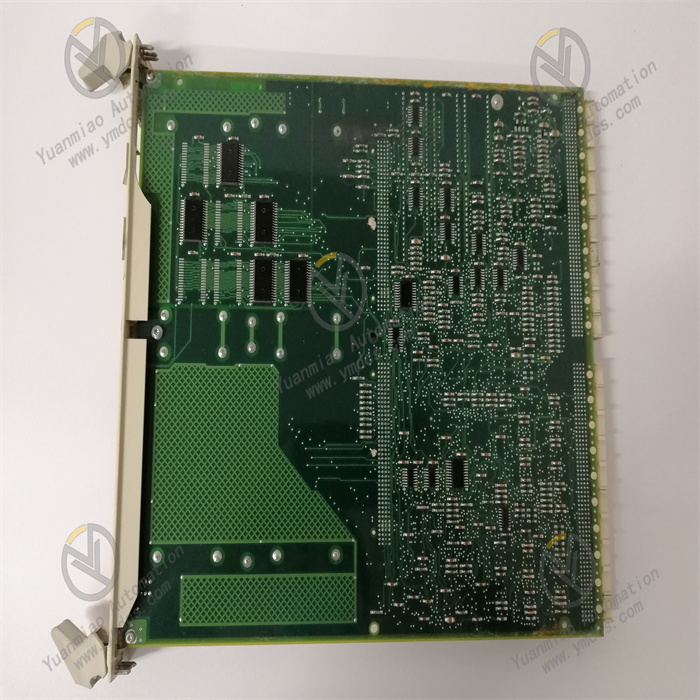

ABB SC520M 3BSE016237R1

I. Overview

ABB SC520M 3BSE016237R1 is a multi-functional module, with its core positioning as a dedicated carrier for MB300/MB300E series sub-modules + local edge computing unit. The suffix "M" in the model stands for Marine, representing the marine enhanced version of the SC520 series. It integrates physical support, electrical adaptation, local data processing and high-reliability protection functions. It can not only provide a stable installation base, power supply and signal links for sub-modules, but also realize local logical operation and edge computing through the built-in 32-bit CPU, reducing the load of the main controller. It is a core component of automation systems in scenarios such as ships, offshore platforms and marine engineering.

II. Core Features

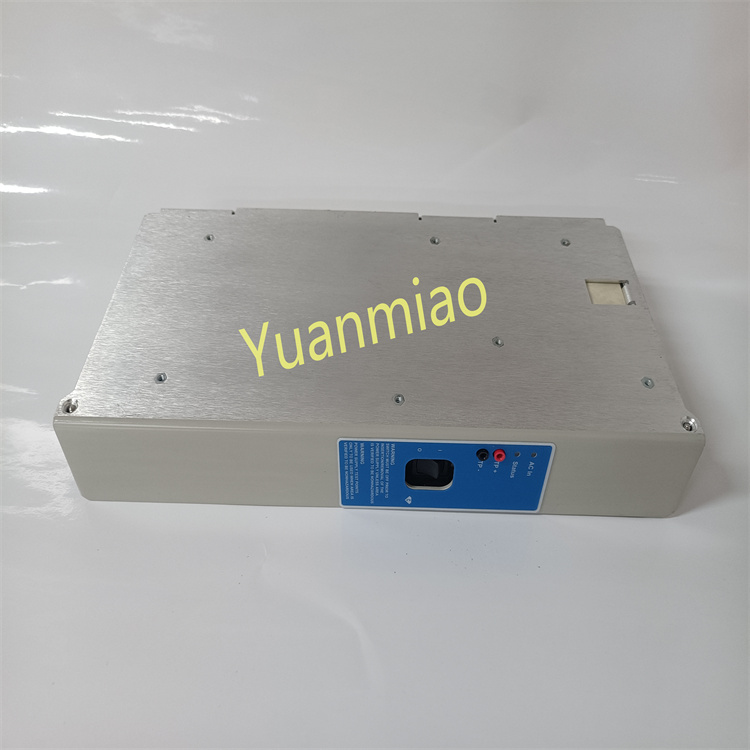

Marine-grade Enhanced Protection Design: The surface is treated with anti-corrosive coating, offering excellent resistance to salt spray, humidity and corrosion. The vibration-resistant structural design is suitable for the bumping conditions of ships. With an IP65 protection class, it can effectively prevent dust and water jets, meeting the stringent protection requirements of marine environments. It has also obtained certifications from classification societies such as DNV GL and ABS.

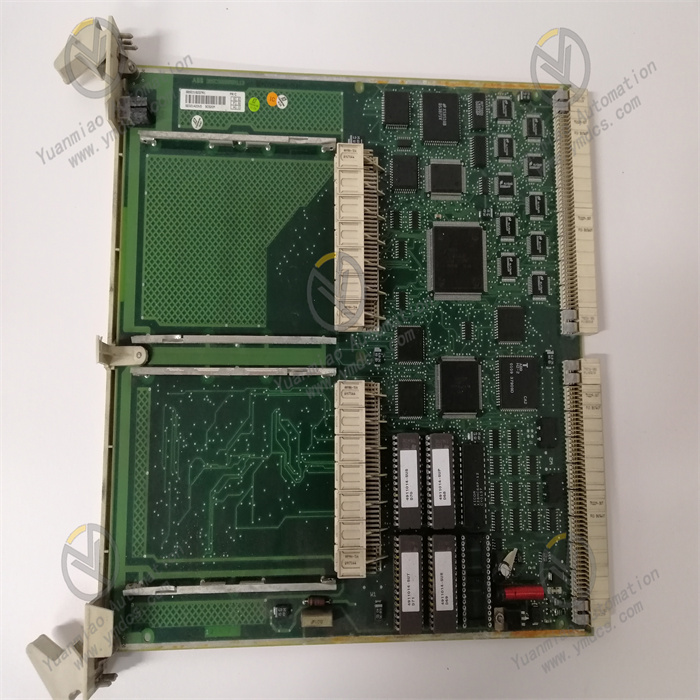

Sub-module Carrying and Expansion: Specifically designed for ABB MB300 and MB300E series sub-modules, it provides standardized installation positions and precise electrical connections, supporting the expansion of multiple types of sub-modules (I/O modules, communication modules). It is compatible with standard SC520 modules, enabling flexible adaptation to different system architectures to meet functional expansion needs.

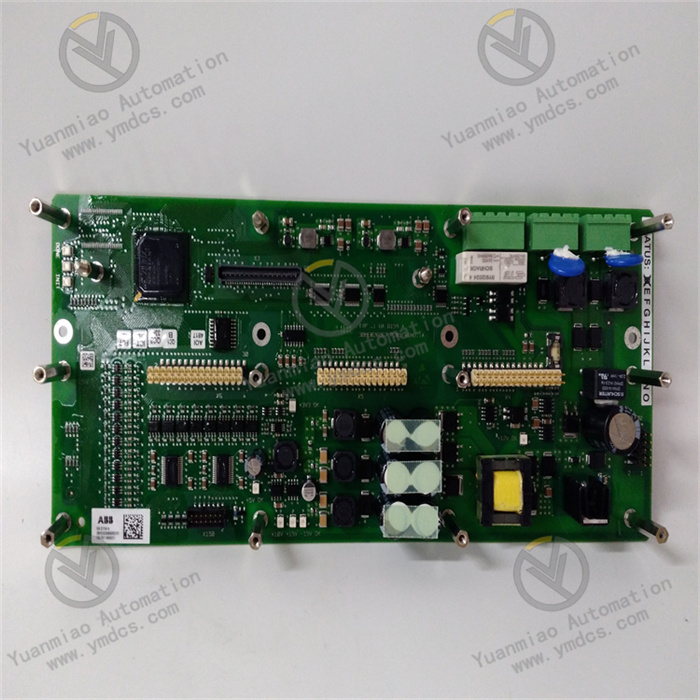

Local CPU and Edge Computing: Equipped with a 32-bit RISC CPU with a main frequency of 120MHz, 512KB program memory and 512KB data memory, it supports IEC 61131-3 standard programming languages. It can implement local logical operation, data processing and control decision-making, reducing data interaction with the main controller, lowering network latency and improving system response speed.

High Reliability and Redundancy Capability: Supports dual 24V DC redundant power input to enhance power supply continuity; features hot-swapping function, allowing module replacement without shutting down the system for easy maintenance; integrates Ethernet interface, supporting remote diagnosis and monitoring through the ABB Support Portal to reduce operation and maintenance costs.

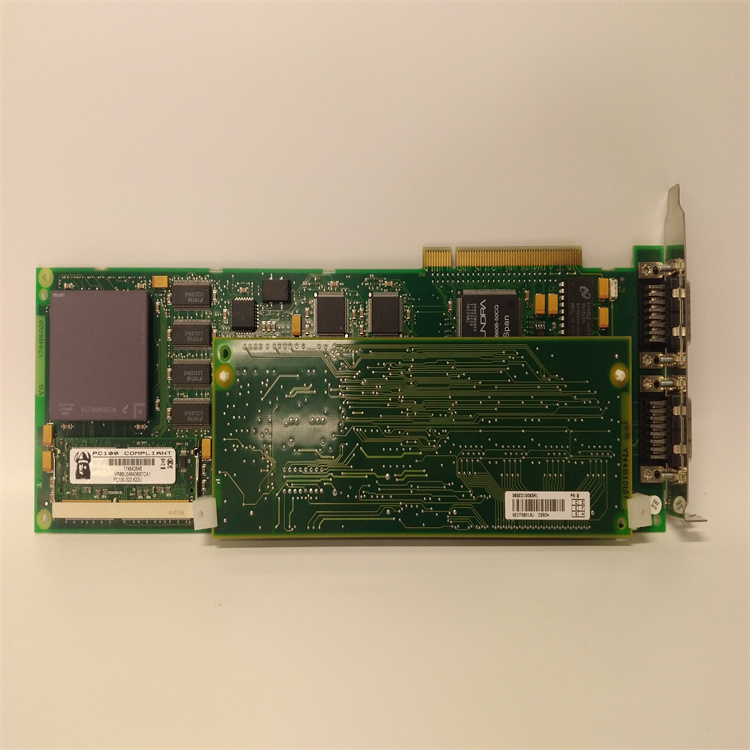

- Multi-protocol Communication and Seamless Compatibility: Supports mainstream industrial protocols such as Modbus RTU/TCP, CANopen and Profibus; integrates 2 RS-232/485 serial communication interfaces, and can expand fieldbus functions through optional modules; highly compatible with ABB AC500 series, 800xA and AC 800M control systems.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB SC520M 3BSE016237R1 |

| Product Type | Marine-grade sub-module carrier (with local CPU), enhanced version of SC520 series |

| Compatible Modules | ABB MB300, MB300E series sub-modules, compatible with standard SC520 modules |

| Core Configuration | 32-bit RISC CPU (120MHz main frequency); 512KB program memory, 512KB data memory |

| Communication Parameters | Integrated 2 RS-232/485 interfaces; supports Modbus RTU/TCP, CANopen, Profibus; Ethernet expansion optional |

| Power Supply Method | Dual 24V DC redundant input (±20% fluctuation tolerance), powering sub-modules via backplane |

| Protection Performance | IP65 protection class; anti-corrosive coating, vibration-resistant structure; operating temperature -25℃~+60℃, storage temperature -40℃~+85℃ |

| Installation Method | TS35 DIN rail mounting, supporting hot-swapping |

| Dimensions | 291mm (depth) × 300mm (height) × 30mm (width) |

| Product Weight | Net weight approx. 0.742kg |

| Compatible Systems | ABB AC500, 800xA, AC 800M control systems, Advant series controllers |

IV. Working Principle

The core working principle of the ABB SC520M 3BSE016237R1 module is a collaborative process of carrier support - power distribution - local computing - data interaction. Through the linkage of marine-grade protection design and multi-functions, it achieves stable operation and efficient control in harsh environments. The specific working process can be divided into four core stages:

Stage 1: Module Carrying and Electrical ConnectionInsert MB300/MB300E series sub-modules accurately into the dedicated installation positions. The module provides physical fixation and electrical connection through built-in interfaces, establishing stable power supply and signal transmission channels. Meanwhile, the anti-corrosive and vibration-resistant structure ensures the stable operation of sub-modules under marine working conditions.

Stage 2: Redundant Power Supply and Safety ProtectionThe dual 24V DC power input distributes stable voltage to the module itself, built-in CPU and loaded sub-modules through the internal power distribution unit, resisting the impact of voltage fluctuations. The IP65 protection and anti-corrosive structure block the intrusion of external salt spray, moisture and dust, protecting the internal circuit from damage.

Stage 3: Local Computing and Data ProcessingThe built-in CPU executes local logical operation, PID regulation, data acquisition and filtering through preset programs to realize edge computing functions. It reduces the amount of data interaction with the main controller, lowers network latency and main controller load, and improves the real-time response capability of the system.

V. Common Fault Troubleshooting

1. Sub-modules Unresponsive, Signal Transmission Interrupted

2. Abnormal Local CPU Operation, Response Delay

3. Remote Diagnosis Failed, Unable to Monitor Remotely