Description

GE DS200FGPAG1AHD

I. Overview

The GE DS200FGPAG1AHD is a high-performance control module playing a critical role in the field of industrial automation, belonging to GE's classic LS2100 series. With its excellent design philosophy and reliable quality, this series is highly favored in complex and changeable industrial environments. The DS200FGPAG1AHD inherits the series' advantages, demonstrating strong functionality and adaptability.

Its core functions focus on fine-grained signal processing, including high-precision amplification of weak signals from sensors and other input sources, as well as precise shaping of pulse signals, ensuring the integrity and accuracy of signals during transmission and use, and laying a solid foundation for the stable operation of industrial systems. Take industrial production lines as an example: signals collected by various sensors need to be processed by the DS200FGPAG1AHD to accurately convey the operating status of equipment, thereby ensuring smooth production processes.

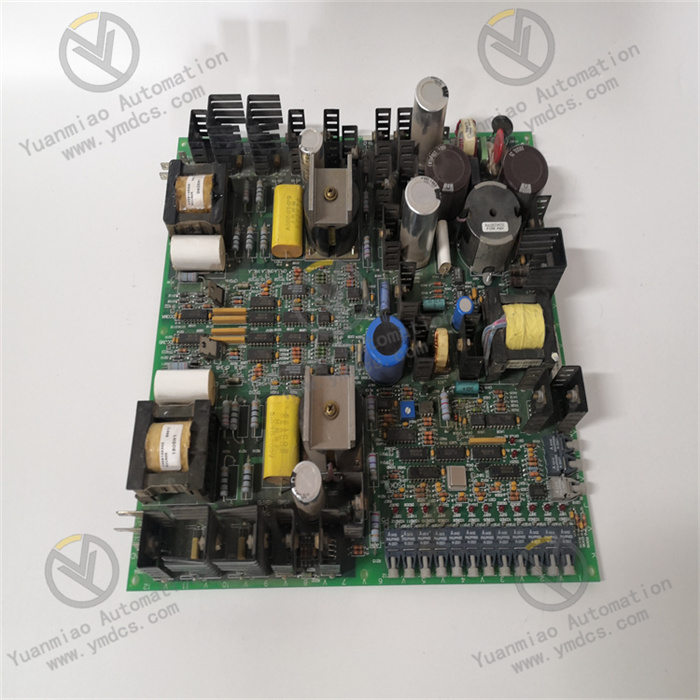

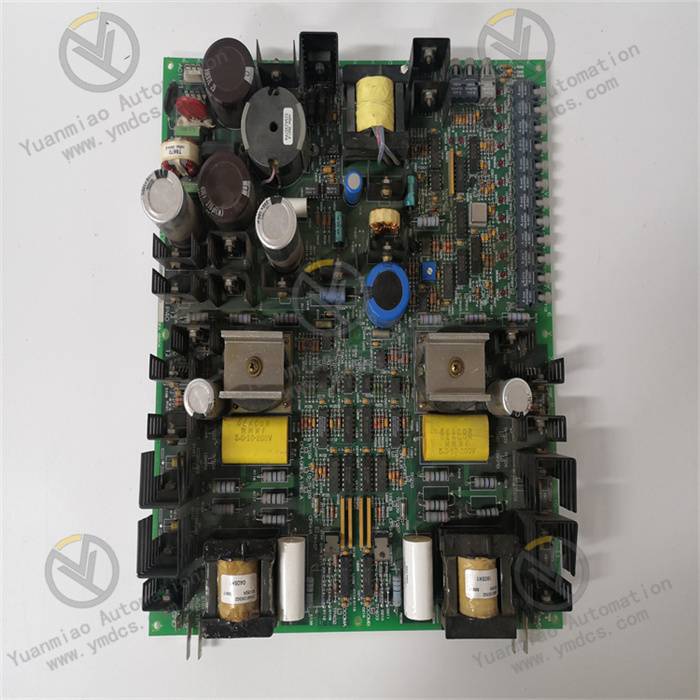

In terms of driving power semiconductor devices, the DS200FGPAG1AHD performs excellently, capable of efficiently driving key devices such as IGBTs and MOSFETs. By providing stable and adaptive gate signals, it precisely controls the switching status of equipment, achieving precise regulation of power electronic systems. It is widely applied in fields with strict power control requirements, such as industrial drives and power conversion.

The module features multi-functional integration. In addition to signal processing and power device driving, it also has a built-in SCR status monitoring function, which can real-time monitor the working status of thyristors. Paired with switching power supplies and gate drivers, it provides comprehensive support for the stable operation of the entire system. Moreover, its modular design is a notable highlight, not only facilitating quick location and replacement of faulty modules during maintenance, effectively reducing downtime and maintenance costs but also enabling flexible configuration adjustments according to different industrial scenarios to adapt to diversified and complex control tasks.

Facing harsh industrial working environments, the DS200FGPAG1AHD is no less impressive. It uses industrial-grade high-quality components to ensure reliability at the hardware level, capable of stable operation even under extreme conditions such as high temperature, high humidity, and strong electromagnetic interference, greatly expanding application scenarios. Whether in scorching steel smelting workshops or humid chemical production sites, it can work reliably.

II. Technical Parameters

1. Power Parameters

- Input Voltage: It shows wide compatibility. The basic input voltage supports 24V DC, and some models can adapt to AC 115 - 230 VAC, even further expanding to AC 90 - 260 VAC, adapting to various global industrial standard power supplies, reducing adaptation challenges caused by power differences, and ensuring stable power acquisition in different power supply environments.

- Output Voltage: The output voltage varies according to models, with common output ranges of ±25V or 0 - 10V, capable of providing appropriate drive voltages for various actuators, sensors, and power semiconductor devices to meet the diverse requirements of different devices for voltage amplitude.

- Power Consumption: The typical power consumption is 5W. While ensuring high-performance operation, it strictly controls energy consumption, conforming to the development trend of modern industry for energy conservation and efficiency improvement, helping to reduce long-term operating costs of enterprises.

2. Electrical Parameters

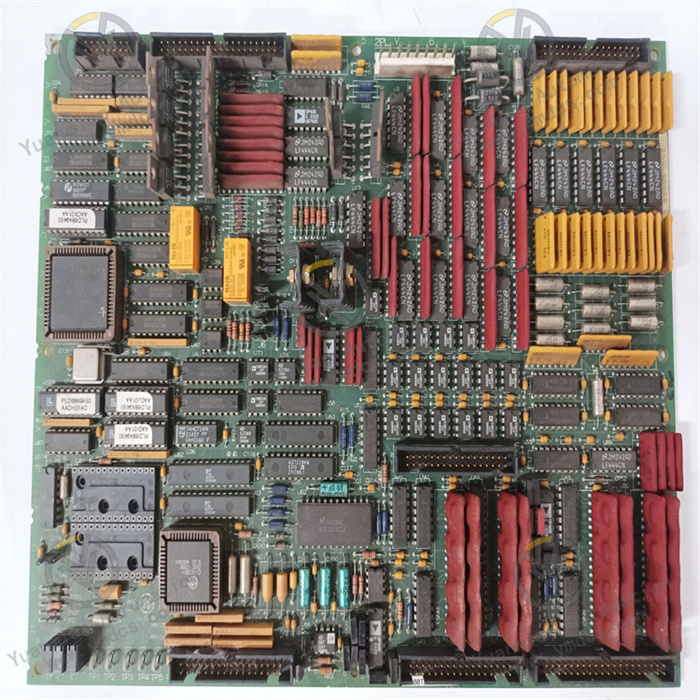

- Number of Channels: It has 16 input/output channels, capable of processing multiple signals simultaneously, greatly improving signal processing efficiency and system integration, facilitating connection of multiple sensors, actuators, and other devices to realize signal interaction and control for collaborative work of multiple devices in complex industrial systems.

- Frequency Response: The frequency response range is 20Hz to 20kHz, capable of precisely processing signals within this frequency band. Whether low-frequency slow-varying signals or high-frequency fast pulse signals, they can be accurately captured and processed, ensuring the timeliness and accuracy of signal processing to meet the processing requirements of industrial automation systems for different frequency signals.

- Gain Adjustment: It supports adjustable gain function. Users can flexibly adjust the gain multiple according to the difference in signal strength in actual application scenarios, ensuring weak signals are effectively amplified and over-strong signals do not distort, enhancing the module's adaptability to complex signal environments.

- Communication Interfaces: Equipped with rich and diverse communication interfaces, covering standard communication protocol interfaces such as Modbus TCP/IP, RS232, and RS485. This enables the DS200FGPAG1AHD to conveniently interact data with other devices and control systems, easily integrate into various complex industrial automation networks, realize rapid data transmission and sharing, and promote the intelligent and integrated development of industrial systems.

3. Mechanical and Environmental Parameters

- Operating Temperature Range: The operating temperature range is extremely wide, reaching -40°C to 85°C, with some materials showing -40°C to 70°C. This excellent temperature adaptability makes it fearless of various extreme climatic conditions and complex industrial environment temperature changes worldwide. Whether in cold polar industrial facilities or hot desert factories, it can operate stably to ensure the continuity of industrial production.

- Humidity Range: It can work reliably in an environment with a relative humidity of 5% to 95% (non-condensing), demonstrating good humidity tolerance, effectively avoiding the risk of circuit failures caused by humidity changes, and ensuring normal operation in scenarios such as humid coastal area factories or industrial production workshops with large humidity fluctuations.

- Protection Level: The protection level is IP20, with certain dust-proof capability, which can block larger dust particles from entering the module interior, providing basic protection for internal precision circuits and extending equipment service life to a certain extent.

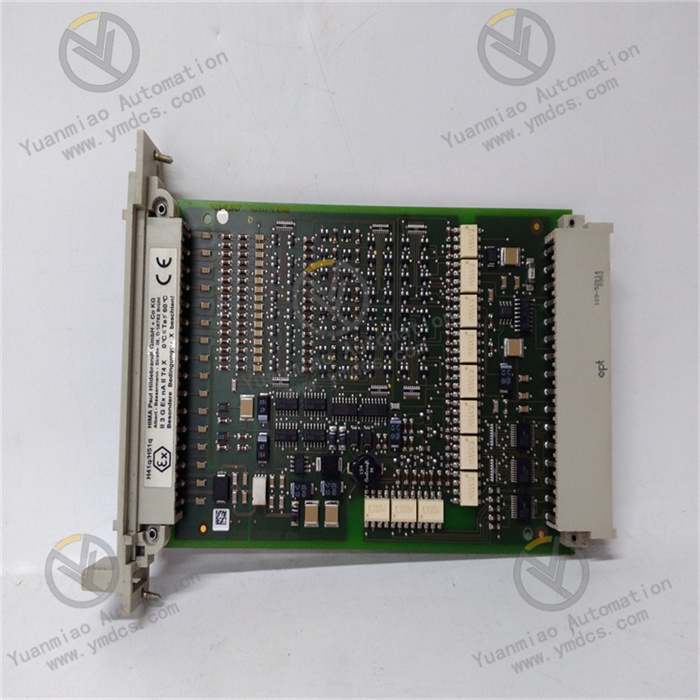

- Dimensions and Weight: In terms of dimensions, some models are 100mm x 80mm x 20mm. The compact shape design gives it significant advantages when installing in industrial control cabinets and equipment interiors with limited space, facilitating flexible layout; other models have dimensions of 170mm x 105mm x 32mm, weighing about 120g. The moderate weight is convenient for handling and installation operations, and it will not cause excessive burden on the installation structure during equipment operation.

III. Working Principle

1. Principle of Signal Amplification and Shaping

When the DS200FGPAG1AHD is connected to an industrial automation system, weak signals from sensors or other input sources first enter the input channel. The internal signal amplification circuit amplifies the signal according to the preset gain value. This amplification circuit adopts advanced operational amplifier technology, featuring low noise and high gain accuracy, which can amplify signals while minimizing noise interference to ensure signal purity.

For pulse signals, the pulse shaping circuit in the module plays a role. It adjusts and optimizes parameters such as the waveform, width, and amplitude of the pulse through specific logic circuits and filtering algorithms. For example, when the input pulse signal has distortion or noise interference, the shaping circuit can identify and remove the interference part, adjusting the pulse signal into a standard rectangular wave, ensuring reliable transmission and use of the signal in the industrial system and providing accurate data support for subsequent control decisions.

2. Principle of Power Device Driving

When driving power semiconductor devices (such as IGBTs and MOSFETs), the gate driver of the DS200FGPAG1AHD plays a key role. The control signal is processed and transmitted to the gate driver, which generates gate drive signals that meet the working requirements of power devices according to control instructions.

Taking the IGBT as an example, the gate driver will output pulse signals with appropriate amplitude and width to the IGBT gate according to the requirements of the control signal. When the IGBT needs to be turned on, a high-level pulse is output, forming a sufficient voltage difference between the IGBT gate and emitter, thereby turning on the IGBT to realize power transmission of the circuit; when the IGBT needs to be turned off, a low-level pulse is output, the IGBT gate voltage decreases, the device turns off, and the circuit is cut off. By precisely controlling the timing and parameters of the gate signal, the DS200FGPAG1AHD can efficiently and stably drive power semiconductor devices to achieve precise control of power electronic systems.

3. Principle of SCR Status Monitoring

The SCR status monitoring function of the DS200FGPAG1AHD relies on its internal status monitoring circuit. This circuit real-time collects working parameters of the SCR (thyristor), such as voltage, current, and other information through a specific connection method with the SCR.

Taking voltage monitoring as an example, the status monitoring circuit will real-time detect the voltage value across the SCR and compare it with the preset normal working voltage range. Once the voltage value exceeds the normal range, such as overvoltage or undervoltage, the monitoring circuit will quickly feedback the abnormal signal to the control system. At the same time, through the monitoring of SCR current, it can be judged whether the SCR is in a normal conduction or off state. If the current increases abnormally, it may mean that the SCR has a short-circuit fault, and the monitoring circuit will also issue a fault signal in a timely manner for the control system to take corresponding measures to ensure the safe operation of the system.

4. Communication Workflow

When the DS200FGPAG1AHD needs to communicate with other devices or control systems, its built-in communication interface circuit works according to the adopted communication protocol (such as Modbus TCP/IP, RS232, RS485).

If using Modbus TCP/IP protocol for Ethernet communication, the module first encapsulates the internal data to be sent in the Modbus TCP/IP protocol format, adds corresponding packet headers, addresses, function codes, and other information, and packages it into a data packet conforming to the Ethernet transmission format. Then, the data packet is sent to the industrial Ethernet network through the Ethernet physical interface and transmitted to the target device or control system. When receiving data, the module real-time monitors the Ethernet interface. Once a data packet is received, it immediately unpacks the packet, extracts valid data, and transmits the data to the internal processing unit for subsequent analysis and control decision-making.

For RS232 and RS485 serial communication methods, the module also processes data according to the corresponding protocols. Since RS485 uses a half-duplex communication mode, the module will strictly follow the timing specified by the RS485 protocol to control data sending and receiving. When sending data, it converts the internal data into RS485 signal level format and sends it through the serial port line at the set baud rate; when receiving data, it converts the received RS485 signal into a digital signal, unpacks it, and passes it to the internal processing unit to realize data interaction with other serial devices and ensure the accuracy and stability of communication.