Description

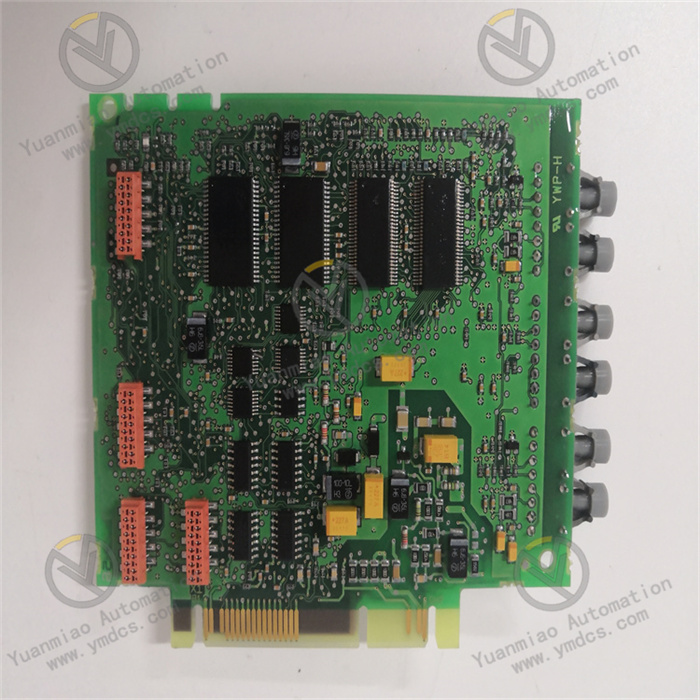

DS215SLCCG1AZZ01B

I. Overview

GE DS215SLCCG1AZZ01B is a LAN communication board meticulously designed by General Electric (GE) for its Mark V turbine control system board series. This series is widely applied in management and control systems for automation drive components of wind, steam, and gas turbines. Although the Mark V series has now become an obsolete legacy product, it remains highly regarded as one of GE's last product lines adopting the patented Speedtronic control system technology, which first debuted with the launch of the Mark I series in the mid-to-late 1960s. The DS215SLCCG1AZZ01B LAN communication card uses a special component version identified by DS 215 and is optimized through a separate Class A functional product revision. Compared with the DS 215 SL CCG 1 motherboard initially developed for the Mark V series, it features Class A revision and optional software packages, offering more powerful functions.

II. Functional Features

- High-performance Communication Capability: Supports multiple communication protocols (e.g., Modbus), executes LAN communication via isolated and non-isolated circuits, and connects with local networks like DLAN and Arcnet. It ensures fast and accurate data transmission in complex industrial environments, enabling efficient data interaction with other devices or systems.

- Excellent Environmental Adaptability: With an ultra-wide operating temperature range of -40°C to +70°C, it operates stably in harsh industrial environments (e.g., extreme heat or cold), adapting to diverse regional and operational requirements. The standard PCB coating resists environmental interference to ensure stable device operation.

- Convenient System Integration: Powered by 24V DC and installed via DIN rail, it easily integrates into existing systems, simplifying system design and installation, reducing construction difficulties and costs, and enhancing overall system compatibility and stability.

- Reliable Safety Assurance: Built-in multiple safety functions (e.g., data encryption, access control, transmission verification) comprehensively protect data security and integrity during transmission, effectively preventing leakage and tampering. Surface mount technology ensures stable connections, further enhancing data transmission security.

- Real-time Operating System Support: Runs on the QNX operating system, renowned for efficiency and reliability, ensuring real-time device operation to meet strict timeliness requirements in industrial control.

- Continuous Optimization and Improvement: Functional revisions A and Z, as well as circuit board artwork revision Z, reflect the product’s ongoing upgrades to better adapt to market and user needs.

III. Technical Parameters

- Input Voltage: 24VDC, compatible with common DC power inputs to ensure stable power supply.

- Operating Temperature Range: -40°C to +70°C, demonstrating strong environmental adaptability for different working scenarios.

- Storage Temperature Range: -40°C to +85°C, ensuring reliability during storage in various temperature environments.

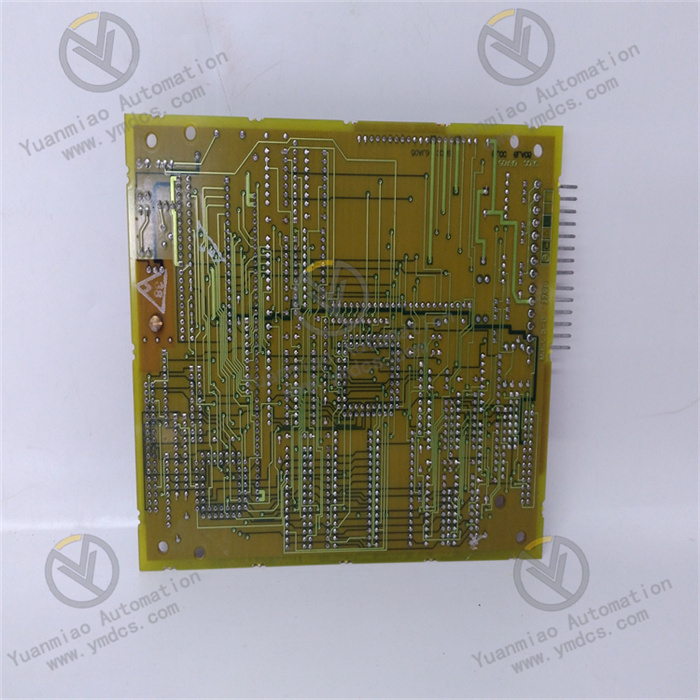

- Dimensions: 125mm (L) × 100mm (W) × 40mm (H), with a compact design for easy installation in control cabinets and equipment spaces.

- Weight: 0.5kg, lightweight for convenient installation and handling.

- Connectivity: Equipped with 2 RS-485 ports and 1 Ethernet port to meet diverse device connection needs.

- Communication Rate: Supports 9600 bps to 1 Mbps, adjustable flexibly according to actual requirements.

- PCB Coating: Standard coating for effective circuit board protection.

- Functional Revisions: Versions A and Z, reflecting continuous functional improvements.

- Circuit Board Artwork Revision: Version Z, indicating optimizations in design layout.

- Operating System: QNX system, providing software support for efficient and stable device operation.

- Installation Method: DIN rail mounting, quick and easy to fix on standard rails.

- Technology Type: Surface mount technology, enhancing the reliability and stability of electronic component installation.

IV. Working Principle

During control system operation, the LAN Control Processor (LCP) of DS215SLCCG1AZZ01B plays a core role. When the device needs to interact with other systems, the LCP first establishes connections with local networks (e.g., DLAN and Arcnet) via the board’s isolated and non-isolated circuits. For example, in an industrial automation production line, sensors collect equipment operation data, which is transmitted to DS215SLCCG1AZZ01B in specific signal forms. The LCP processes the received signals, converts them into digital signals, and packages and encodes the data according to preset communication protocols. The processed data is then sent to target devices or systems via network interfaces. Conversely, when receiving data from other systems, the LCP decodes and verifies the data based on communication protocols to ensure accuracy and integrity, then transfers the processed data to other system components for subsequent processing. The board’s main microprocessor and system memory support the LCP’s efficient operation, ensuring smooth data processing and communication.

V. Common Faults and Solutions

- Data Transmission Interruption or Error

- Fault Phenomenon: Frequent data packet loss, transmission interruptions, or errors during communication with other systems.

- Solutions: First, check communication lines for looseness, damage, or poor contact, and repair or replace them promptly. Then, verify communication protocol settings, recheck compatibility with other devices, and adjust if incorrect. If the issue persists, the communication interface module may be faulty; test by replacing the module to identify and resolve the problem.

- Device Fails to Recognize Network

- Fault Phenomenon: The device cannot detect surrounding DLAN or Arcnet networks after startup, disabling communication.

- Solutions: Check network configuration parameters (IP address, subnet mask, gateway, etc.) to ensure they match the network environment. Verify that network connection devices (switches, routers, etc.) are working normally and try restarting them. If unresolved, hardware failures (e.g., a damaged network chip) may exist, requiring professional maintenance or replacement.

- Device Overheating

- Fault Phenomenon: The casing temperature rises excessively after operation, possibly triggering overheat protection and causing performance degradation or shutdown.

- Solutions: Check the heat dissipation environment to ensure good ventilation and no debris blocking the channels. Verify that the cooling fan operates normally and replace it if faulty (e.g., stalled or abnormal speed). If the device runs under high load for extended periods, optimize communication task allocation to adjust workload and reduce power consumption.