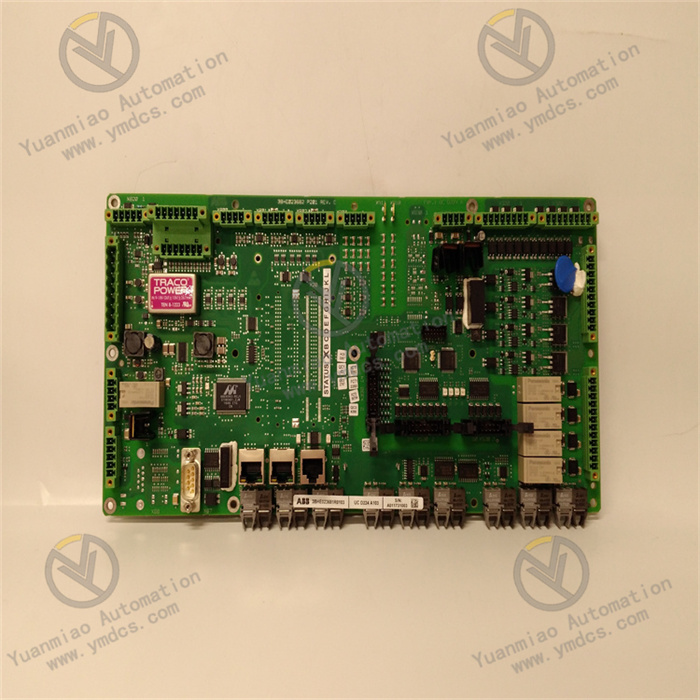

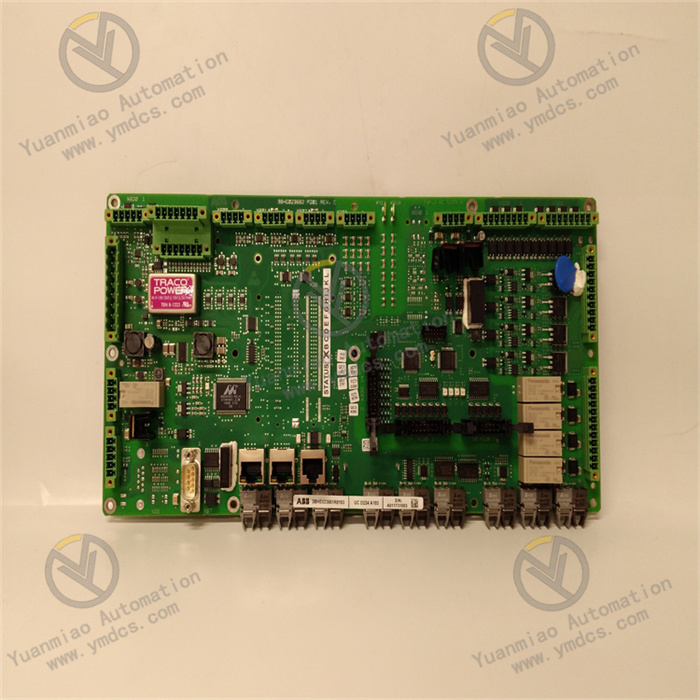

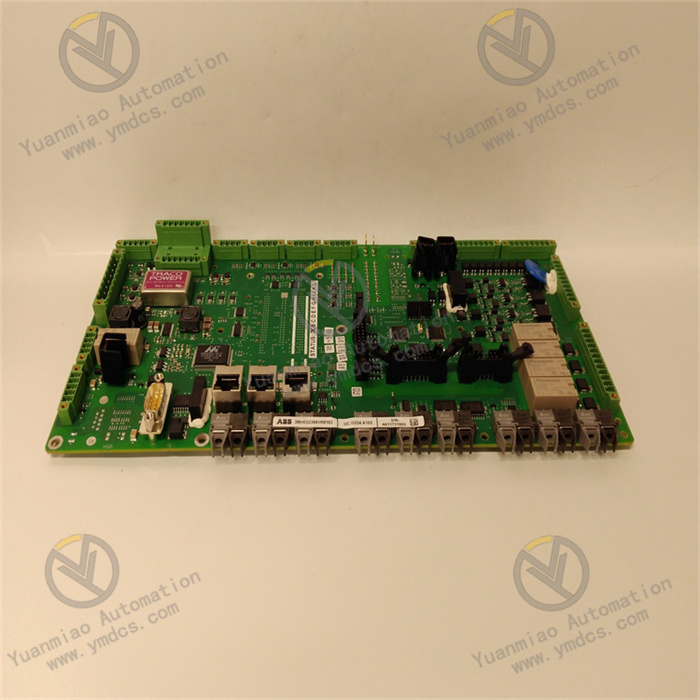

Description

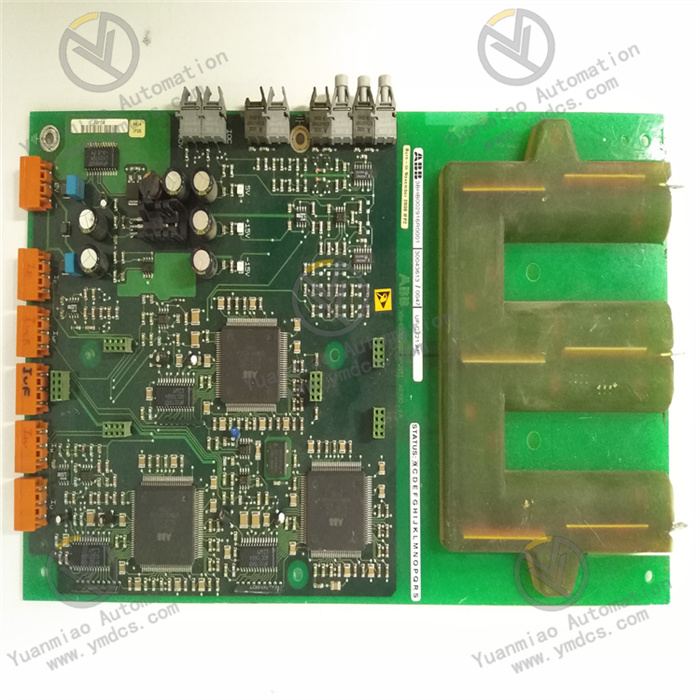

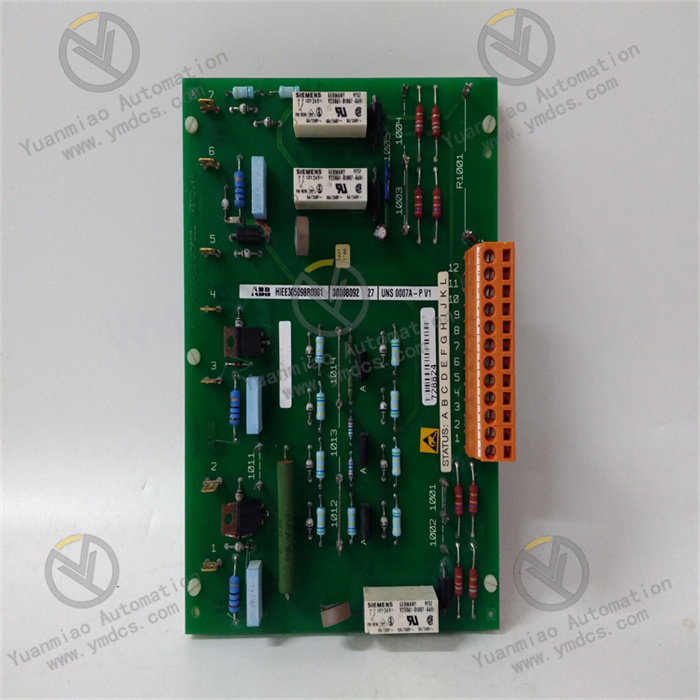

Technical Parameters Number of channels: There may be multiple input and output channels. For the specific number, please refer to the product manual. For example, there may be 24 channels, which are used to connect various field devices to achieve signal collection and output of control commands. Input and output types: It supports various types of input and output signals, such as analog input (AI), analog output (AO), digital input (DI), digital output (DO), etc., to meet the interface requirements of different industrial field devices. For example, it may have high-precision analog input channels that can accurately collect analog signals from field sensors, such as temperature, pressure, flow rate and other signals, and convert them into digital signals for processing by the control system. Signal range: The analog input channels may support multiple standard signal ranges, such as 0 - 10V, 4 - 20mA, etc., and can be configured according to the type of sensor actually connected. The digital input and output channels usually adopt standard industrial levels, such as 24V DC logic level. Accuracy: It has high measurement and control accuracy to ensure accurate monitoring and control of industrial processes. For example, the accuracy of analog input may reach ±0.1% or higher, which can accurately reflect the changes of field signals. Isolation characteristics: To ensure the stability and safety of the system, it usually has good electrical isolation performance. For example, photoelectric isolation or electromagnetic isolation technology is used between channels and between input/output and power supply to prevent interference between different circuits and the spread of electrical faults. The isolation voltage may reach several thousand volts, which can effectively protect the system from external electrical interference and surges. Communication interface: It supports interfaces for communication with the host computer control system or other devices, such as industrial communication protocols like Profibus, Modbus, Ethernet, etc., so as to transmit the collected data to the control system for processing and monitoring, and receive control commands from the control system. The communication rate may vary according to different protocols and interface types. For example, the communication rate of the Profibus interface may be selectable between 9.6Kbps and 12Mbps.

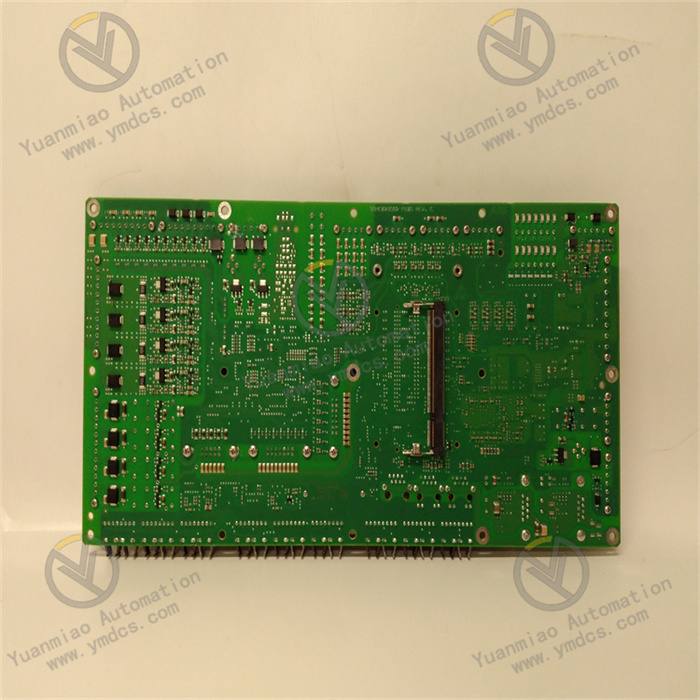

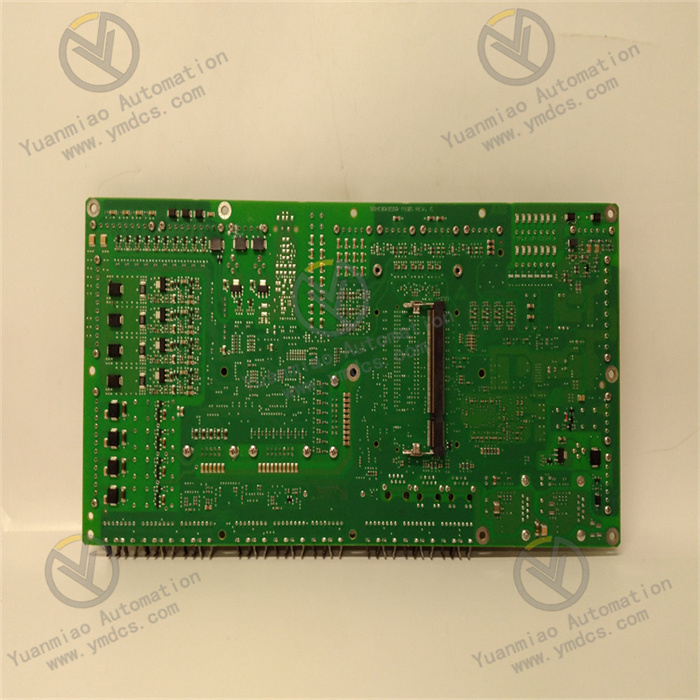

Functional Features High reliability: It uses high-quality electronic components and advanced manufacturing processes. After strict quality inspection and reliability testing, it can operate stably for a long time in harsh industrial environments. It has the abilities of anti-interference, anti-vibration, anti-shock, etc., and can adapt to industrial field conditions such as high temperature, high humidity, and dust. For example, in a high-temperature environment, its heat dissipation design can ensure that the module works within the specified temperature range and will not cause performance degradation or failure due to overheating. Flexible configuration: It can be flexibly configured through software to adapt to different industrial application scenarios. Users can set the types, ranges, filtering parameters, alarm thresholds, etc. of the input and output channels according to actual needs to achieve personalized control schemes. For example, for an industrial production line with various types of sensors, different channels can be set to corresponding input types and ranges through software configuration to accurately collect data from various sensors. Diagnostic function: It has a powerful self-diagnostic function, which can monitor its own working status in real time. When a fault occurs, it can send out alarm signals in a timely manner and provide detailed fault information to help maintenance personnel quickly locate and troubleshoot the fault. For example, the module can detect channel faults, power supply faults, communication faults, etc., and send fault codes and diagnostic information to the outside through indicator lights or communication interfaces, reducing system downtime and improving production efficiency. Redundancy function: In some key industrial applications, to improve the reliability of the system, redundancy configuration may be supported. For example, two UCD224A103 modules can be configured to be redundant to each other. When one module fails, the other module can automatically take over its work to ensure the uninterrupted operation of the system and improve the safety and stability of the industrial process.

Common Faults and Solutions Channel Fault Phenomenon: One or more input and output channels do not work properly, such as being unable to collect correct signals or output control signals. Cause: It may be caused by channel hardware damage, incorrect wiring, incorrect software configuration, or external interference. Solution: First, check whether the wiring of the channel is correct, and whether there are loose, open circuit or short circuit phenomena. If the wiring is normal, check whether the parameter settings of the channel in the software configuration are correct and whether they match the device actually connected. If the above are all normal, it may be a channel hardware fault, and you need to contact ABB's technical support personnel or replace the module. Communication Fault Phenomenon: The module cannot communicate normally with the host computer control system or other devices, resulting in the inability to transmit data or issue control commands. Cause: It may be caused by damage to the communication interface, incorrect communication protocol settings, network connection problems, or electromagnetic interference. Solution: Check whether the connection of the communication interface is normal, and whether there is looseness or damage. Confirm whether the settings of the communication protocol are consistent with those of the opposite device, including parameters such as baud rate, data bits, stop bits, and parity bits. Check whether the network connection is normal. If necessary, use network detection tools to check the network status. If electromagnetic interference is suspected, check whether there are strong interference sources around and take corresponding anti-interference measures, such as using shielded cables and adding filters. Power Supply Fault Phenomenon: The module does not work properly, and the indicator light does not turn on or abnormal alarm information appears. Cause: It may be caused by power input failure, damage to the power module, or problems with the power line. Solution: Check whether the power input voltage is within the specified range. If the voltage is abnormal, check the power supply equipment and power line to eliminate the power supply fault. If the power input is normal, it may be that the power module inside the module is damaged, and you need to contact professional maintenance personnel for maintenance or replace the module.

Application Areas: Industrial automation: In the production lines of the manufacturing industry, it is used to control and monitor various devices, such as motors, valves, sensors, etc., to achieve the automation and optimization of the production process. For example, in the automation production lines of industries such as automobile manufacturing and electronic device manufacturing. Power system: It can be applied to power facilities such as power plants and substations, and is used for the protection, control and monitoring of the power system. For example, it monitors and controls the status of devices such as generators, transformers, and transmission lines to ensure the stable operation of the power system. Process control: In process industries such as chemical, petroleum, natural gas, and pharmaceutical industries, it is used to accurately control and monitor parameters such as temperature, pressure, flow rate, and liquid level in the production process to ensure the safety of the production process and the stability of product quality. Transportation: For example, in railway transportation, it can be used in railway signal systems, control systems of electric vehicles, etc., to ensure the safe and efficient operation of transportation. Building automation: In intelligent buildings, it is used to control the lighting system, air conditioning system, elevator system, etc., to achieve the energy management of buildings and the automated operation of equipment, and improve the comfort and energy efficiency of buildings.