Description

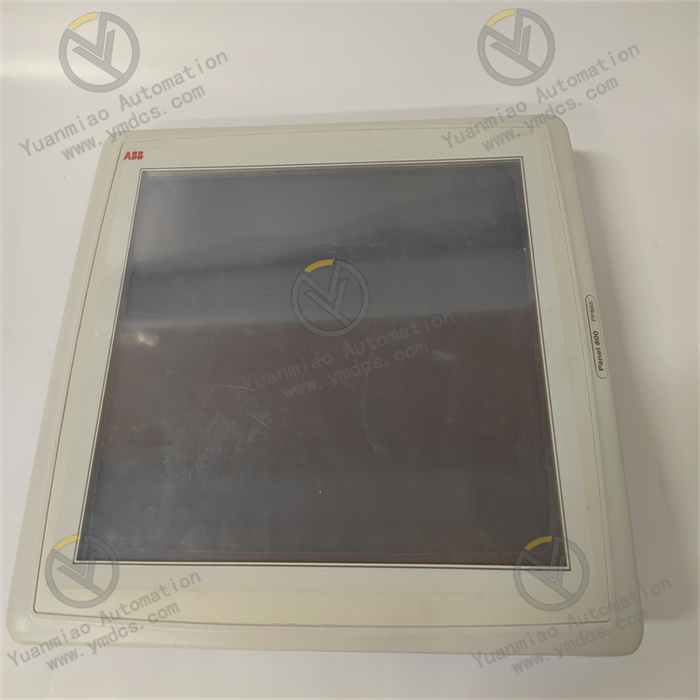

ABB PCS6000 PRODUCT FAMLIY 3BHE055094R0002 GBU72

Overview

The ABB PCS6000 product family is a series of high-performance power conversion and control systems launched by ABB, mainly targeting fields such as new energy power generation, industrial drives, and grid energy storage, dedicated to providing efficient and reliable power electronics solutions. This family covers multiple product lines including converters, controllers, and power modules. Through modular design and advanced control algorithms, it realizes precise conversion of electric power between different forms (AC and DC) and different voltage levels. Meanwhile, it has strong system integration capabilities and intelligent operation and maintenance functions, serving as a core equipment family for achieving efficient energy utilization and precise control in modern power systems and industrial automation fields.

Core Product Types

- PCS6000 Converter Series: As the core products of the family, they include grid-connected converters, energy storage converters, and industrial converters. Grid-connected converters can convert DC power or variable-frequency AC power generated by new energy sources (such as solar energy, wind energy) into power-frequency AC power that meets grid standards, with a conversion efficiency of over 98.5%. They support a wide input voltage range and can adapt to the volatility of new energy power generation. Energy storage converters realize bidirectional power conversion between the power grid and energy storage systems: storing electrical energy in battery packs during low grid load periods and releasing it during peak load periods, with a response time of no more than 50ms, effectively mitigating grid fluctuations. Industrial converters are mainly used for industrial motor drives, enabling stepless speed regulation of motors with a wide speed range of 0.1-3000rpm, meeting the speed requirements of different industrial equipment.

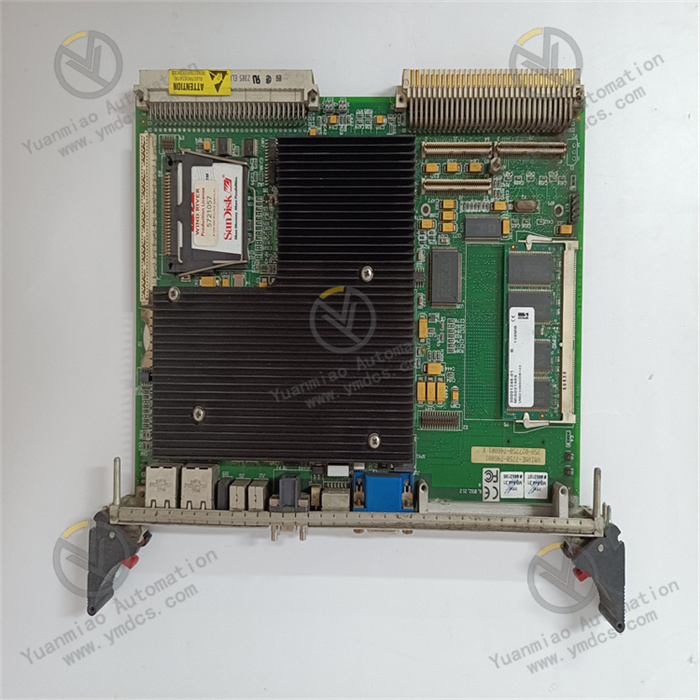

- PCS6000 Controller Series: As the "brain" of the converter, the controller adopts a multi-core processor architecture with a main frequency of 1GHz, supporting real-time control algorithms and complex logic operations. It can monitor the operating parameters of the converter in real-time (such as voltage, current, temperature) and dynamically adjust the converter's output according to grid commands or load demands. It also has communication functions with upper-level monitoring systems, supporting multiple industrial protocols such as PROFINET and Modbus, facilitating remote monitoring and system integration.

- PCS6000 Power Module Series: Serving as the core of the converter's power conversion, they adopt advanced IGBT (Insulated Gate Bipolar Transistor) devices. A single module has a rated power of up to 500kW and supports parallel operation of multiple modules, with a total power scalable to tens of megawatts. The power modules are equipped with comprehensive protection functions, including overcurrent, overvoltage, and overtemperature protection. They adopt liquid-cooled or air-cooled heat dissipation designs, enabling stable operation in high-temperature environments.

- PCS6000 Monitoring and Operation & Maintenance System: Connected to PCS6000 series equipment via industrial Ethernet, it can collect real-time operating data, fault information, and energy efficiency indicators of the equipment, generating visual reports and trend curves. The system supports remote diagnosis and predictive maintenance. By analyzing the operating status data of the equipment, it can early warn potential faults, reduce downtime, and improve system availability.

Technical Features

- Efficient Energy Conversion: PCS6000 converters adopt advanced Space Vector Pulse Width Modulation (SVPWM) technology, with a power factor close to 1 (lagging or leading) and a Total Harmonic Distortion (THD) of less than 3%. This greatly reduces harmonic pollution to the power grid and improves energy conversion efficiency. In new energy grid connection and industrial motor drives, it can significantly reduce energy loss and enhance the energy-saving performance of the system.

- Strong Adaptability and Scalability: The product family adopts a modular design with standardized interfaces between components, supporting flexible configuration and power expansion. For example, in large-scale photovoltaic power plants, multiple PCS6000 grid-connected converters can operate in parallel to meet the needs of power plants with different capacities. When the system needs upgrading, only the corresponding power modules or controllers need to be replaced or added, without reconstructing the entire system, reducing upgrade costs.

- Precise Control Performance: The controller's high-speed computing capability and advanced control algorithms (such as model predictive control) ensure the stability and accuracy of the converter's output. In energy storage systems, it can precisely control charging and discharging current and voltage, achieving refined management of batteries and extending battery life. In industrial drives, it can realize high-precision speed and torque control of motors, meeting the requirements of precision processing equipment.

- High Reliability and Safety: The entire product series has passed strict industrial certifications (such as IEC and UL standards) and has characteristics such as anti-electromagnetic interference, anti-vibration, and corrosion resistance, adapting to harsh industrial environments. Both power modules and controllers adopt redundant designs. When a component fails, the redundant component can automatically switch, ensuring uninterrupted system operation. Meanwhile, the comprehensive protection mechanism can quickly respond to faults, preventing equipment damage and safety accidents.

Typical Application Scenarios

- Large-Scale Photovoltaic Power Plant Grid-Connected System: In gigawatt-level photovoltaic power plants, PCS6000 grid-connected converters convert DC power generated by photovoltaic arrays into high-voltage AC power and integrate it into the grid. The controller adjusts the output power according to grid dispatching instructions to achieve efficient utilization of photovoltaic power. The monitoring system monitors the power generation efficiency and equipment status of the power plant in real-time, ensuring stable operation and maximizing power generation.

- Grid-Level Energy Storage System: PCS6000 energy storage converters are responsible for power conversion between batteries and the grid in grid energy storage systems. When grid load is low, the converter converts grid electricity into DC power and stores it in batteries; during peak load periods, it converts the DC power from batteries back into AC power and feeds it into the grid, playing a role in peak shaving and valley filling. The controller maintains grid frequency and voltage stability through precise control of the charging and discharging process.

- Industrial Motor Drive System: In heavy industries such as steel and cement, PCS6000 industrial converters are used to drive large asynchronous or synchronous motors. For example, in the drive system of rolling mills in steel plants, the converter can adjust motor speed and torque in real-time according to changes in roll load, ensuring the stability of the rolling process and product quality. At the same time, stepless speed regulation reduces the starting impact of the motor, extending equipment life.

- New Energy Vehicle Charging Pile Cluster: PCS6000 converters can serve as the core of power conversion for charging piles, converting grid AC power into DC power to charge new energy vehicles. The controller dynamically distributes power according to the load demands of the charging piles, supporting simultaneous charging of multiple piles and improving charging efficiency. The monitoring system records charging data, realizing intelligent management and maintenance of the charging piles.

Summary

With efficient energy conversion, strong adaptability, and precise control performance, the ABB PCS6000 product family plays a key role in new energy, industrial drives, grid energy storage, and other fields. Its modular design and intelligent operation and maintenance functions not only reduce the construction and operation costs of the system but also improve the reliability and availability of equipment, providing strong support for the efficient and stable operation of modern energy systems and industrial automation.