Description

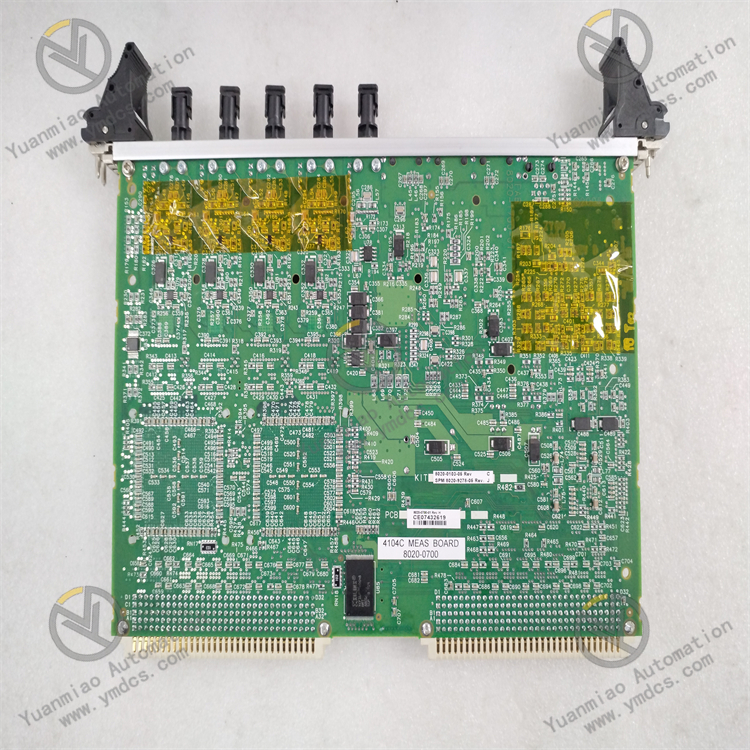

ZYGO 4104C

I. Product Overview

II. Technical Parameters

Number of measurement axes: It supports up to four measurement axes and can connect four interferometers simultaneously to achieve multi-dimensional displacement measurement. This multi-axis measurement capability has obvious advantages in complex measurement scenarios, being able to comprehensively and accurately obtain displacement information of objects in different directions, providing researchers and engineers with richer and more comprehensive data to help them deeply understand the movement state and changes of the measured object.

Interface type: It adopts the VME (VersaModule Eurocard) interface, which is a standard interface widely used in high-performance data acquisition and control systems. Through the VME interface, the 4104C can quickly and stably perform data interaction and communication with other devices, ensuring the efficiency and reliability of data transmission. At the same time, it also supports RS232 or RS485 interfaces, facilitating connection with some traditional devices or devices with relatively low requirements for communication rate, which greatly enhances the compatibility and applicability of the device, enabling it to better integrate into various types of measurement systems.

Laser parameters (if it is a pulsed laser type): If the 4104C is a pulsed laser type, its laser wavelength is 1064 nanometers, which has good applicability in fields such as material processing. The peak power can reach 2 kilowatts, able to provide strong energy output to meet process requirements that require high laser energy such as material cutting, drilling, and welding. The repetition frequency ranges from 10 Hz to 200 Hz, and users can flexibly adjust it according to specific processing tasks and material characteristics. The pulse width is from 10 nanoseconds to 50 nanoseconds, and a shorter pulse width can achieve more precise processing effects and reduce the heat-affected area of the material.

Optical measurement-related parameters (if it is an optical surface measuring instrument type): When the 4104C is used as an optical surface measuring instrument, its measurement range is very wide, covering a scale from 0.1 nm to 6.5 mm, capable of both micro-level nanoscale surface defect detection and macro-level overall measurement of larger-sized optical components. The measurement accuracy reaches an impressive 0.01 nm, able to accurately measure extremely small topographic changes and quality differences on the surface of optical components. The measurement time is between 5 - 60 seconds, and users can flexibly choose the appropriate measurement time according to different measurement tasks and accuracy requirements, ensuring measurement accuracy while maximizing measurement efficiency. It uses a HeNe laser as the light source, which has high stability and good monochromaticity, able to provide a stable and high-quality light beam for measurement. Equipped with a high-sensitivity CCD camera as a detector, it can quickly and accurately capture reflected light signals, thereby achieving precise measurement of optical surfaces.

III. Functional Features

Cyclic error compensation function: It uses patented cyclic error compensation technology, which can automatically and seamlessly eliminate the inherent nonlinear errors common in DMI systems. This error compensation function is crucial for improving the accuracy and repeatability of measurements, especially in scenarios that require multiple repeated measurements or long-term continuous measurements. It can ensure the consistency and reliability of each measurement result, avoiding measurement deviations caused by system errors, and providing reliable data support for scientific research experiments and industrial production.

Advantages of modular design: It adopts a modular design concept and has excellent expandability. It can work in collaboration with other ZMI™ series boards, easily expanding to up to 64 measurement axes. This modular design provides users with great flexibility. Whether it is a simple small-scale measurement system or a complex large-scale industrial automation measurement network, users can build the most suitable measurement solution by reasonably adding or combining modules according to actual needs, effectively reducing the system construction cost and the difficulty of later upgrade and maintenance.

Automatic calibration function (some models): Some models of the 4104C have an automatic calibration function. The device can automatically calibrate its own measurement parameters and accuracy regularly or when needed by the user, ensuring that the device is always in the best working condition. This function greatly reduces the workload and human error of manual calibration, improves the accuracy and stability of measurement, and is especially suitable for application scenarios that require long-term continuous operation or have extremely high requirements for measurement accuracy, such as batch inspection of optical components.

IV. Application Fields

Semiconductor manufacturing field: It plays a key role in the entire process of semiconductor manufacturing. In the lithography process, high-precision control of the displacement of the lithography machine's workbench is required. The 4104C can monitor the tiny displacement of the workbench in real-time, ensuring the precise positioning of the lithography pattern, thereby improving the manufacturing accuracy and performance of the chip. In the chip packaging process, the alignment accuracy between the chip and the substrate is extremely high. The 4104C can be used to measure and adjust the position of the chip, ensuring the accuracy and reliability of the packaging and reducing the rejection rate. In addition, in the research and development and maintenance of semiconductor equipment, it is also necessary to rely on the high-precision measurement function of the 4104C to perform performance testing and fault diagnosis on key components of the equipment, ensuring the normal operation of the equipment.

Precision machinery processing field: In precision machinery processing, the requirements for processing accuracy are increasing. The 4104C can be used to monitor and control the motion accuracy of machine tools. By measuring the relative displacement between the tool and the workpiece in real-time, it can timely adjust the motion parameters of the machine tool to ensure the dimensional accuracy and surface quality of the processed parts. For example, in the processing of components in the aerospace field, many key parts require processing accuracy up to the micron or even nanometer level. The 4104C can provide reliable measurement guarantee for these high-precision processing tasks, ensuring that the processed parts meet strict quality standards.

Scientific research field: In nanotechnology research, scientists need to accurately measure and analyze the growth process, structural changes, and mechanical properties of nanomaterials. The sub-nanometer resolution and multi-axis measurement function of the 4104C make it a powerful tool for nanotechnology research, able to help researchers deeply understand the characteristics and behaviors of nanomaterials and promote the development of nanotechnology. In the field of optical research, the requirements for measuring the surface topography and optical properties of optical components are extremely high. As a high-precision optical surface measuring instrument, the 4104C can be used to measure parameters such as surface roughness and surface shape error of optical lenses, mirrors, and other components, providing important data support for the design and optimization of optical systems. In biomedical research, some high-precision experimental equipment, such as atomic force microscopes, also need to rely on the high-precision displacement measurement function of the 4104C to achieve precise operation and observation of biological samples.