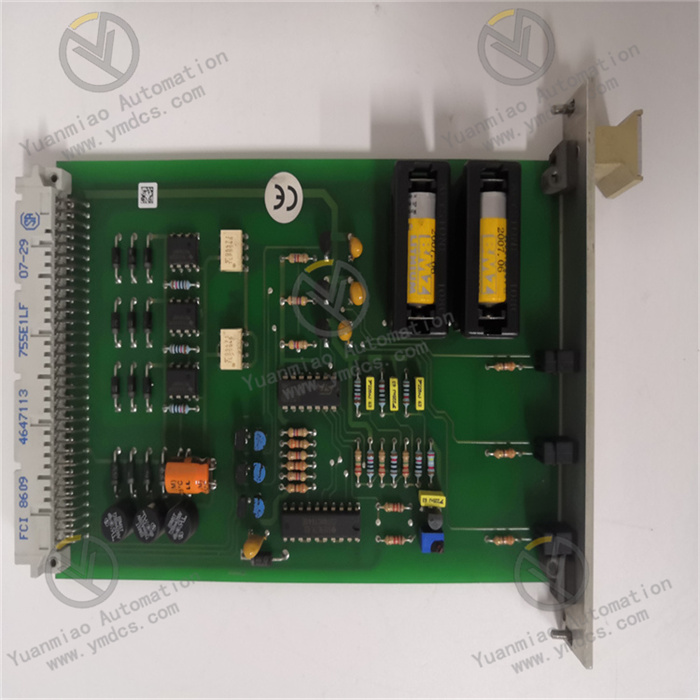

Description

GE IS220YAICS1AL

Functional Features

- High-speed Data Acquisition and Signal Processing: Capable of state monitoring, vibration analysis, temperature monitoring, etc.

- Four Analog Input Channels: Each channel features 12-bit resolution, supports multiple input signal types (e.g., voltage, current, temperature), and can be configured for single-ended or differential input.

- Built-in Signal Conditioner: Amplifies or attenuates input signals, with onboard diagnostic functions.

- Ethernet Connectivity to Mark VIe Controller: Supports mainstream industrial protocols (Modbus TCP/IP, Profinet, Ethernet/IP, etc.) for remote data transmission and real-time monitoring. Seamlessly integrates with other I/O modules, controllers, and HMIs.

- SIL3 Compliance: Suitable for critical process safety applications, operating in harsh industrial environments (high temperature, high humidity, high vibration).

Application Areas

- Primary Applications: Gas turbines, steam turbines, and other industrial process control applications; condition monitoring and protection for rotating equipment such as compressors.

- Extended Applications: Factory automation, process control, building automation, and commercial/residential applications (e.g., security systems, HVAC).

Technical Parameters

- Analog Input Channels: 4 channels

- Input Range: Voltage 0-10V, current 4-20mA

- Input Resolution: 16 bits

- Accuracy: ±0.1%

- Communication Protocols: Supports Modbus TCP/IP, Profinet, Ethernet/IP, etc. Redundant communication available. Complies with SIL3 (Safety Integrity Level 3) for critical process safety applications.

- Operating Environment: Suitable for harsh industrial environments (high temperature, high humidity, high vibration). Low-power design ensures long-term stable operation.

Additional Features: Advanced signal analysis capabilities for high-speed data acquisition and processing, applied to condition monitoring and protection of rotating equipment (gas turbines, steam turbines, compressors, etc.).

Working Principle of GE IS220YAICS1AL Module

1. I/O Module (Input/Output Module)

- Function: Connects field devices (sensors, actuators) to the control system for signal acquisition, processing, and output.

- Input Module:

- Receives signals (voltage, current, switch signals) from field devices, converting them into digital signals via signal conditioning circuits (filtering, amplification, isolation).

- Stores data in module registers for reading by the controller (e.g., CPU) after analog-to-digital conversion (A/D conversion).

- Output Module:

- Receives digital signals from the controller, converting them into power signals (e.g., 24V DC, relay contact signals) via digital-to-analog conversion (D/A conversion) or direct drive circuits.

- Ensures system safety through isolation circuits (e.g., optoelectronic isolation) to avoid external interference.

2. Communication Module

- Function: Enables communication between the control system and external devices, other systems, or host computers, supporting industrial protocols (Modbus, EtherNet/IP, Profibus, etc.).

- Working Principle:

- Parses and encapsulates communication protocol data to ensure reliable data transmission between devices.

- Example: Ethernet modules exchange data with host computers via TCP/IP, while fieldbus modules (e.g., Profibus) communicate with distributed I/O devices via proprietary protocols.

- Typically includes protocol processing chips, communication interface circuits (RJ45, RS-485), and data buffer memory.

3. Control Module (e.g., PID Control Module)

- Function: Implements closed-loop control algorithms (e.g., PID control) to regulate industrial process parameters (temperature, pressure, flow).

- Working Principle:

- Collects real-time feedback signals (input values) from sensors, compares them with setpoints (given values) to generate deviations.

- Calculates output values via PID algorithms to drive actuators (valves, motors) and stabilize process parameters.

- Some modules support parameter self-tuning, alarm threshold setting, and fault diagnosis.

4. Analog Input Module

- Signal Acquisition: Receives analog signals from sensors (e.g., 4-20mA current, 0-10V voltage).

- Signal Processing: Filters noise and amplifies signals to appropriate levels via front-end conditioning circuits.

- Analog-to-Digital Conversion: Converts analog signals to digital quantities (e.g., 16-bit binary data) using high-precision A/D converters.

- Data Transmission: Transmits digital signals to the controller module via internal buses (e.g., PCIe or proprietary buses).

- Fault Detection: Built-in diagnostic circuits monitor signal overrun, disconnection, and other anomalies, reporting faults to the system.

Common Faults and Solutions

1. Power Supply Faults

- Symptoms: No power supply, indicator lights off; power indicator flashing or alarming; power module overheating or emitting odors.

- Causes: Faulty power supply lines (open circuit, short circuit); damaged power adapters/modules; internal power circuit short circuits or component aging.

- Solutions:

- Check input voltage/current against device specifications; replace power cables or sockets.

- Measure power output with a multimeter; replace the module if abnormal.

- Inspect internal power circuits for damaged components (e.g., bulging capacitors, burnt resistors) and replace them (professional operation required).

2. Communication Faults

- Symptoms: No communication with the host computer (PLC, computer); data errors, packet loss, or transmission interruptions; abnormal communication indicator lights (RX/TX).

- Causes: Poor communication cable connections, damage, or mismatched types (e.g., RS-485/RS-232); incorrect communication parameters (baud rate, parity, data bits, stop bits); faulty communication interface chips or driver issues.

- Solutions:

- Replug or replace communication cables; use shielded cables to reduce EMI.

- Ensure device and host computer communication parameters match; reconfigure per the manual.

- Update device drivers or firmware; return for repair or replace the module if interface chips are damaged.

3. Signal Acquisition/Output Faults

- Symptoms: Sensors fail to detect signals (no input module display); actuators unresponsive (no output voltage/current); unstable analog signals or abnormal values (e.g., temperature/pressure fluctuations).

- Causes: Faulty sensors/actuators (damage, loose wiring); malfunctioning signal conditioning circuits (e.g., amplifiers, filters); EMI causing signal distortion (cables near power lines).

- Solutions:

- Test sensor power and output signals with a multimeter; replace faulty sensors.

- Check output module loads and test output voltage/current; replace faulty components.

- Shield and ground signal cables or reroute them away from interference sources.

4. Hardware Damage or Aging

- Symptoms: Frequent crashes, restarts, or functional abnormalities; poor board slot contact causing system errors; oxidized component pins, loose solder joints, or corroded circuit boards.

- Causes: Aging electronic components (capacitors, resistors, chips); environmental factors (dust, humidity, high temperature); mechanical vibration causing loose connections or board fractures.

- Solutions:

- Clean internal dust; replace aging components (e.g., bulging capacitors).

- Replug boards or clean gold fingers with an eraser to ensure good contact.

- Improve the operating environment (add cooling fans, dust covers); repair or replace corroded circuit boards.

5. Software or Configuration Faults

- Symptoms: Abnormal device functions (e.g., ineffective parameter settings, logic control errors); program errors, loading failures, or version incompatibilities.

- Causes: Lost or incorrectly modified configuration files; outdated software or hardware-software incompatibility; logic errors in user-defined programs.

- Solutions:

- Restore factory settings or re-import correct configuration files.

- Upgrade device firmware or install compatible software versions.

- Debug or reset user programs per the manual to correct logic errors.