Description

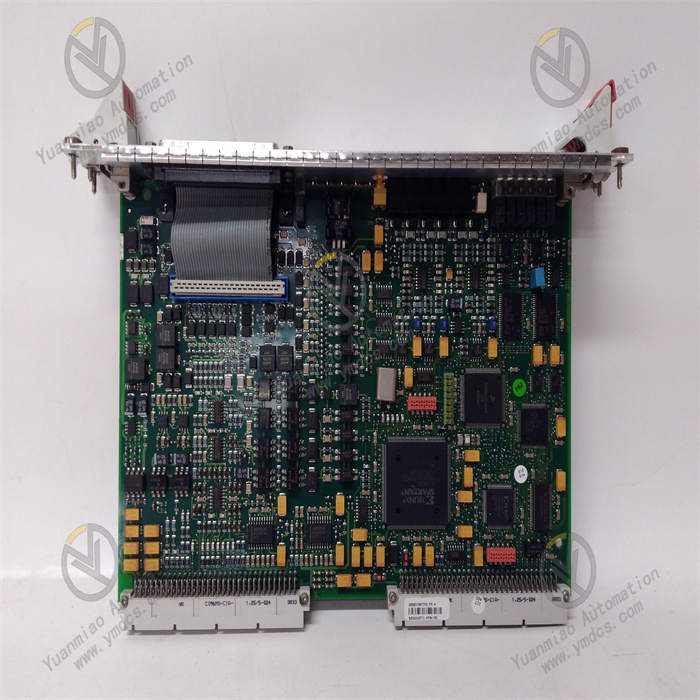

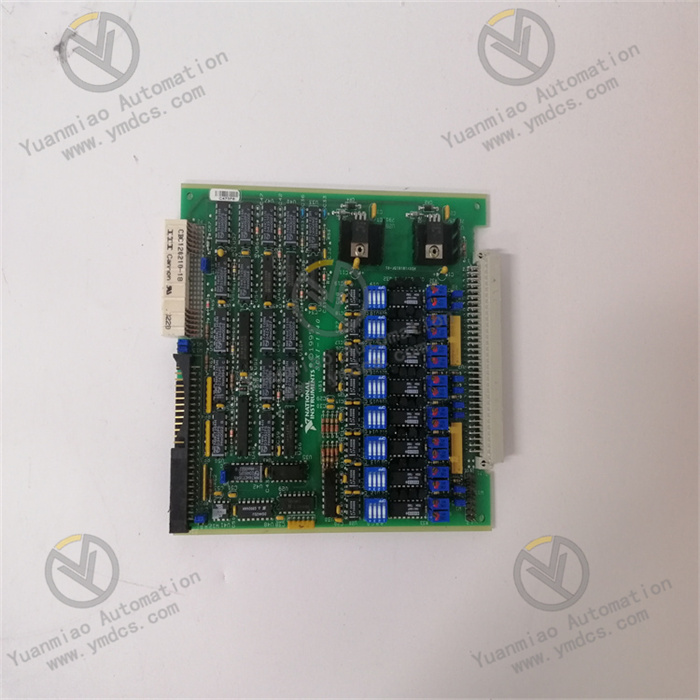

GE IC695CPU315-BB

I. Product Overview

II. Functional Features

Rich programming options: Supports multiple IEC-approved programming languages, such as Ladder Logic, Structured Text, Function Block Diagram, and can also be programmed using C language. The diverse programming methods provide great convenience for engineers with different programming habits and skill levels, enabling them to flexibly choose the most suitable programming method according to project requirements, reducing development difficulty and improving programming efficiency.

Flexible memory configuration: It has 20 MB of user memory (Random Access Memory, RAM) and 20 MB of flash memory. Automatically located symbolic variables can use memory as needed, with a maximum capacity of occupying all 20 MB of user memory, providing sufficient space for the storage and operation of complex programs and the processing of large amounts of data. At the same time, it can reserve 32 kilobits of memory for discrete I/O and 32 kilowords of memory for analog I/O, meeting the needs of different types of data storage and processing.

Convenient communication function: It is factory-configured with two front ports, namely RS - 485 serial port and RS - 232 serial port, supporting SNP, serial I/O, as well as Modbus slave and master serial protocols, facilitating data interaction with various field devices, intelligent option modules, and other control systems. In addition, the rack-based Ethernet interface module can be used to establish Ethernet communication, further expanding the communication range and data transmission capability, and realizing remote monitoring and centralized management.

Good compatibility: It can support most older GE Fanuc Series 90 - 30 modules and expansion racks. In system upgrade or transformation projects, it can effectively utilize existing equipment resources, reduce costs, reduce risks and workload caused by equipment replacement, and provide strong guarantee for the sustainable development of industrial automation systems.

Reliable diagnosis and maintenance support: It supports online testing and diagnosis functions, which can monitor its own working status in real-time. It has a complete fault recording function, which can record the time, type, and related parameters of faults in detail, facilitating maintenance personnel to quickly locate and solve problems. Its firmware can also be upgraded within the system, making it convenient to obtain new functions and performance optimizations in a timely manner, extending the service life of the equipment and improving the overall stability of the system.

III. Technical Parameters

Power supply requirements: The current is 1 ampere at 3.3 volts DC and 1.2 amperes at 5 volts DC, which is compatible with common industrial power supplies to ensure stable operation.

Power consumption: The power consumption during normal operation is within a reasonable range (the specific value is not clearly mentioned, but inferred from the hardware configuration and similar products, the power consumption design focuses on energy saving to reduce operating costs).

Performance parameters:

Processor speed: Up to 1 GHz, providing strong computing power to ensure fast processing of complex instructions and large amounts of data.

Boolean execution speed: The typical Boolean execution speed is 0.047 milliseconds per 1000 Boolean instructions, ensuring efficient logical operations.

I/O operation capability: It can perform up to 32K I/O operations per second, realizing rapid collection of field device status and timely output of control instructions.

Processor speed: Up to 1 GHz, providing strong computing power to ensure fast processing of complex instructions and large amounts of data.

Boolean execution speed: The typical Boolean execution speed is 0.047 milliseconds per 1000 Boolean instructions, ensuring efficient logical operations.

I/O operation capability: It can perform up to 32K I/O operations per second, realizing rapid collection of field device status and timely output of control instructions.

Memory parameters:

User memory: 20 MB of user memory (RAM) is used for program running and data storage, and 20 MB of flash memory is used for non-volatile data storage to ensure data security and reliable program loading.

I/O memory: 32 kilobits of memory are reserved for discrete I/O, and 32 kilowords of memory are reserved for analog I/O, which reasonably allocates memory resources to meet different I/O data processing needs.

User memory: 20 MB of user memory (RAM) is used for program running and data storage, and 20 MB of flash memory is used for non-volatile data storage to ensure data security and reliable program loading.

I/O memory: 32 kilobits of memory are reserved for discrete I/O, and 32 kilowords of memory are reserved for analog I/O, which reasonably allocates memory resources to meet different I/O data processing needs.

Communication parameters:

Serial ports: Equipped with two serial ports, RS - 232 and RS - 485, supporting multiple serial communication protocols to meet different communication distance and device connection requirements.

Communication protocols: Supports SNP, serial I/O, Modbus slave and master serial protocols to achieve communication compatibility with different devices.

Serial ports: Equipped with two serial ports, RS - 232 and RS - 485, supporting multiple serial communication protocols to meet different communication distance and device connection requirements.

Communication protocols: Supports SNP, serial I/O, Modbus slave and master serial protocols to achieve communication compatibility with different devices.

Physical parameters:

Dimensions: (The specific dimensions are not clearly given, but as an industrial module, it is compactly designed to fit into the installation space of standard industrial control cabinets, facilitating integration into various systems).

Weight: (The specific weight is not mentioned, but it is inferred to be lightweight in design, facilitating installation and transportation).

Dimensions: (The specific dimensions are not clearly given, but as an industrial module, it is compactly designed to fit into the installation space of standard industrial control cabinets, facilitating integration into various systems).

Weight: (The specific weight is not mentioned, but it is inferred to be lightweight in design, facilitating installation and transportation).

Environmental parameters:

Operating temperature: The operating temperature range is 0 to 60 degrees Celsius, which can adapt to temperature changes in most conventional industrial environments to ensure stable operation.

Humidity: (Although the humidity range is not clearly specified, referring to similar industrial products, it can work normally under common industrial environmental humidity and has a certain moisture-proof capability).

Operating temperature: The operating temperature range is 0 to 60 degrees Celsius, which can adapt to temperature changes in most conventional industrial environments to ensure stable operation.

Humidity: (Although the humidity range is not clearly specified, referring to similar industrial products, it can work normally under common industrial environmental humidity and has a certain moisture-proof capability).

IV. Working Principle

Signal conversion and processing: The received analog signals are converted into digital signals by the internal analog-to-digital converter. Together with the directly input digital signals, they are processed by the 1 GHz Intel Celeron - M microprocessor through operations and logical judgments according to the user-written control program. In the process control system, the control quantity is calculated based on sensor data such as temperature and pressure to determine whether it is necessary to adjust the equipment operating parameters.

Instruction execution and control output: The microprocessor executes corresponding control instructions according to the processing results. If abnormal equipment operation is detected, such as overcurrent or overheating, it immediately sends control signals to the actuators through the output interface, controlling the relay to act to cut off the power supply or adjust the equipment operating status to ensure equipment safety. In the automated assembly line, it controls the start and stop of motors, the running speed of conveyor belts, etc.

Communication interaction: It uses RS - 232, RS - 485 serial ports, and Ethernet interfaces to conduct data communication with other devices or systems. The collected equipment operating data, fault information, etc., are transmitted to the human-machine interface (HMI), monitoring system, or other upper computers, so that operators can understand the system status in real-time. It can also receive control instructions and parameter settings from the upper computer to realize remote control and system optimization.