Description

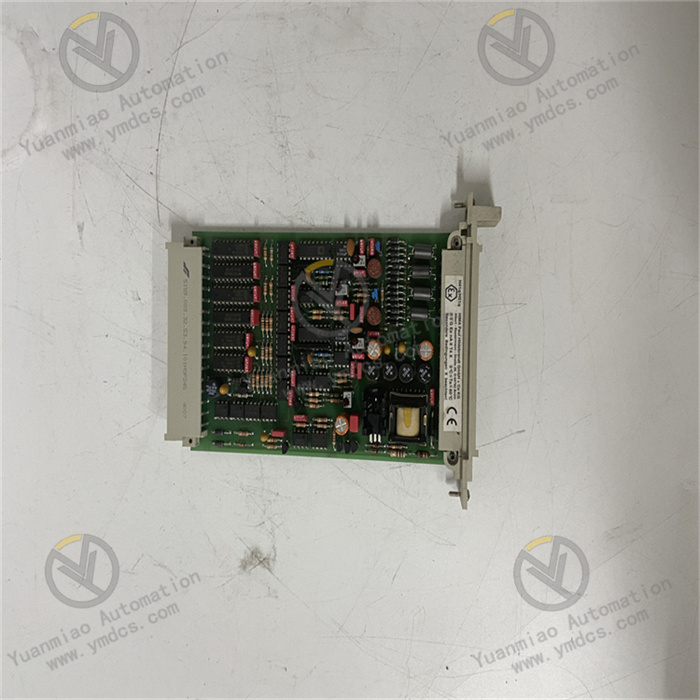

ABB TK803V018 3BSC950130R1

I. Overview

The TK803V018 3BSC950130R1 is an industrial automation control module belonging to the I/O module of the AC 800M series PLC. Primarily used for signal collection and output control in industrial fields, this module supports analog and digital signal processing, suitable for complex industrial scenarios such as power, petrochemical, metallurgy, and papermaking. Designed in compliance with high-reliability standards, it features electromagnetic interference resistance and wide-temperature operation, ensuring stable performance in harsh environments. It serves as one of the core components of Distributed Control Systems (DCS) and process automation systems.

II. Functional Features

Multi-Type Signal Processing Capability

- Supports Analog Input/Output (AI/AO) and Digital Input/Output (DI/DO), adapting to signal interaction with sensors (e.g., temperature, pressure, flow) and actuators (e.g., valves, motors).

- High-precision signal conversion: 16-bit resolution for analog input ensures accurate data collection.

Flexible Communication and Expansion

- Integrates industrial communication protocols like Modbus and Profibus, enabling real-time communication with PLC master units, HMIs, or SCADA systems.

- Supports hot-swapping for convenient system maintenance and expansion, allowing module replacement without shutdown.

High-Reliability Design

- Wide operating temperature range: -25°C to +70°C, adapting to high/low-temperature industrial environments.

- Interference resistance: Complies with EN 61000 electromagnetic compatibility standards, withstanding on-site electromagnetic interference.

- Fault diagnosis function: Built-in self-diagnosis mechanism displays module status (power, communication, fault) in real time via LED indicators.

Convenient Engineering Configuration

- Supports programming with ABB Control Builder software, compatible with IEC 61131-3 standard programming languages (e.g., LD, FBD, ST).

- Supports redundant configuration to enhance system reliability, suitable for high-safety scenarios (e.g., emergency shutdown systems).

III. Technical Parameters

| Parameter Category | Specific Indicators |

|---|---|

| Power Supply Voltage | 24V DC (±10%), power consumption ≤5W |

| Signal Types | - Analog input: 4-20mA, 0-10V, thermocouples, RTDs, etc. - Analog output: 4-20mA, 0-10V - Digital input/output: 24V DC switching signals |

| Channel Quantity | Typical configuration: 16 analog inputs / 8 analog outputs or 32 digital inputs / 32 digital outputs (subject to model specifications) |

| Resolution | Analog: 16 bits; Digital: 1 bit |

| Communication Interfaces | - 1×Profibus DP slave interface - 1×RS485/RS232 (supports Modbus RTU) |

| Physical Dimensions | Approximately 100mm × 25mm × 110mm, weight approx. 0.2kg |

| Protection Level | IP20 (suitable for installation in control cabinets) |

| Certification Standards | CE, UL, ISO 9001, compliant with industrial safety standards |

IV. Working Principle

As an I/O module, the TK803V018 core function is to enable interaction between industrial field signals and control systems, with the workflow as follows:

Signal Collection Stage

- Receives sensor signals (e.g., analog current/voltage signals, digital switching signals) through input channels and converts analog signals to digital (A/D conversion).

Signal Processing and Transmission

- Preprocesses collected signals (filtering, amplification, etc.), transmits them to the PLC master unit via the internal bus, or directly drives outputs based on preset logic.

Control Output Stage

- Receives control commands from the master unit, converts digital signals to analog (D/A conversion) or directly outputs digital signals to drive actuators (e.g., control valves, relays).

Communication and Diagnosis

- Interacts with upper-level systems via communication interfaces, while real-time monitoring hardware status (e.g., channel faults, power anomalies) and feedbacking fault information through indicators.

V. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Power light (PWR) off | Loose power connection or voltage anomaly | Check power cable connections, measure input voltage within 24V DC (±10%), and replace faulty power modules. |

| No signal input in channels | Sensor failure, loose wiring, or channel damage | Replace sensors, check terminal connections; test channels via diagnostic software and replace modules if damaged. |

| Abnormal output signals | Actuator power failure, output channel damage, or parameter configuration error | Check actuator power, reconfigure output parameters (e.g., range, type); test output channels and replace modules if necessary. |

| Communication interruption | Communication cable failure, address conflict, or protocol configuration error | Replace communication cables, verify Profibus or Modbus parameters (e.g., baud rate, slave address) for correctness. |

| Module overheating alarm | High ambient temperature or poor heat dissipation | Add control cabinet cooling fans, clean module heat sinks; ensure ambient temperature does not exceed 70°C. |

| Abnormal LED indicator flashing | Internal hardware failure or program error | Restart the module, check program logic via Control Builder software; contact ABB technical support for persistent faults. |

VI. Extended Application Scenarios

The TK803V018 is commonly used with ABB AC 800M series CPU modules, S800 I/O systems, and third-party devices. Typical applications include:

- Power industry: Generator set temperature/pressure monitoring, substation switching quantity control;

- Chemical industry: Reactor liquid level/flow regulation, distillation column temperature closed-loop control;

- Water treatment: Water quality parameter (pH, turbidity) collection and dosing control in sewage treatment plants;

- Manufacturing industry: Sensor signal collection and robotic arm motion control in automated production lines.